PLA 140.207.000.000RE

3

1. Content

1. Description and work .................................................................................................................................... 5

1.1. DPS-140 Desription and work .................................................................................................................... 5

1.1.1. DPS-140 Purpose........................................................................................................................... 5

DPS-140 in a complex with DEL-140, DEL-150, DEL-150Еis designed to control of drawworks shaft

rotation of drilling and workover rigs.............................................................................................................. 5

1.1.2. DPS-140 Modifications and its technical characteristics:................................................................. 5

Table 1 –Main technical characteristics and DPS-140(А,E) parameters.......................................................... 5

Table 2 –Main technical characteristics and parameters DPS-140(I)............................................................... 5

Table 3-Main technical characteristics and parameters DPS-140(P)................................................................. 5

Table 4–Dimensions, weight ......................................................................................................................... 6

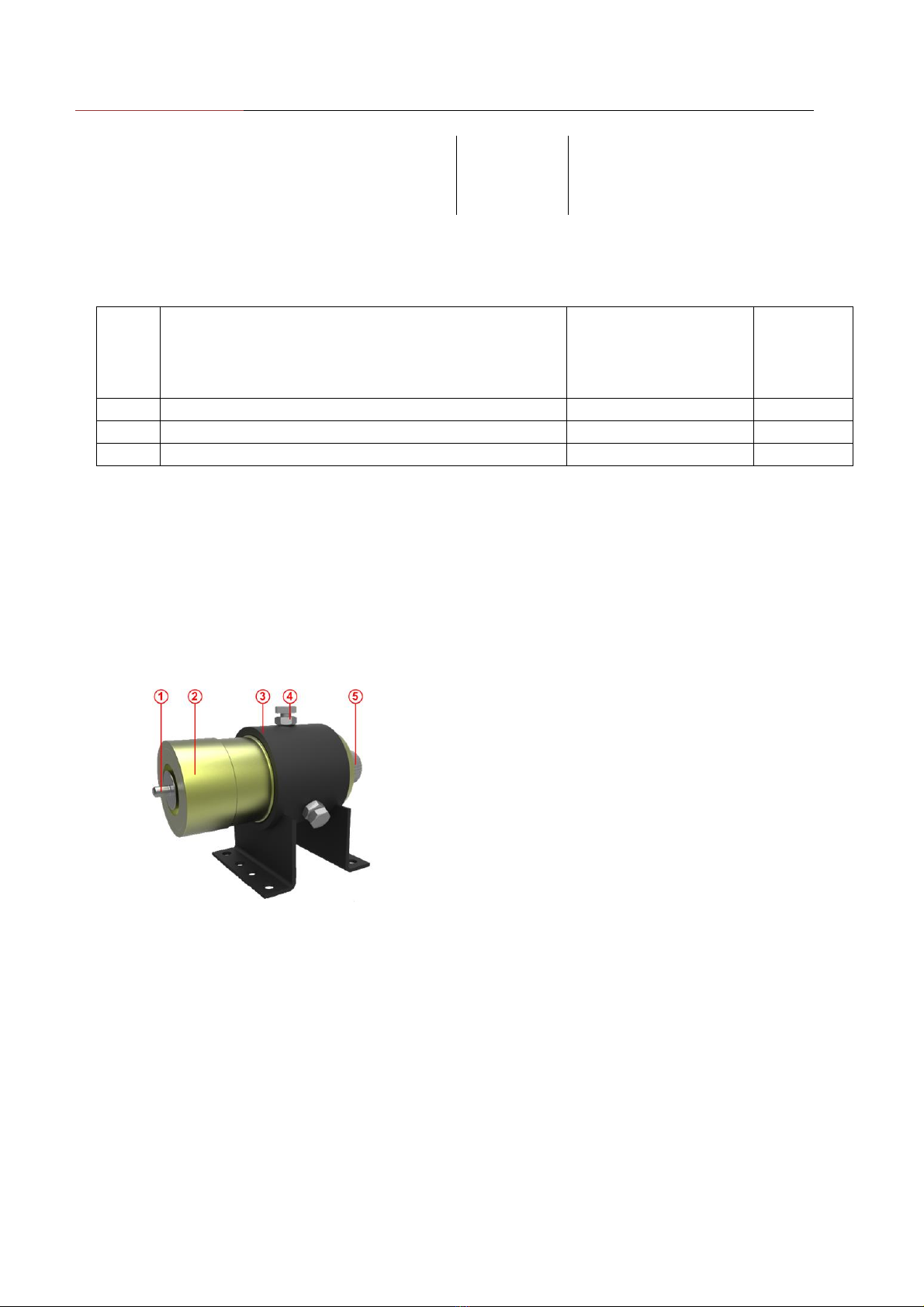

1.1.3. Content DPS-140(А,E)................................................................................................................... 6

Figure 1 –DPS-140(А) .................................................................................................................................. 6

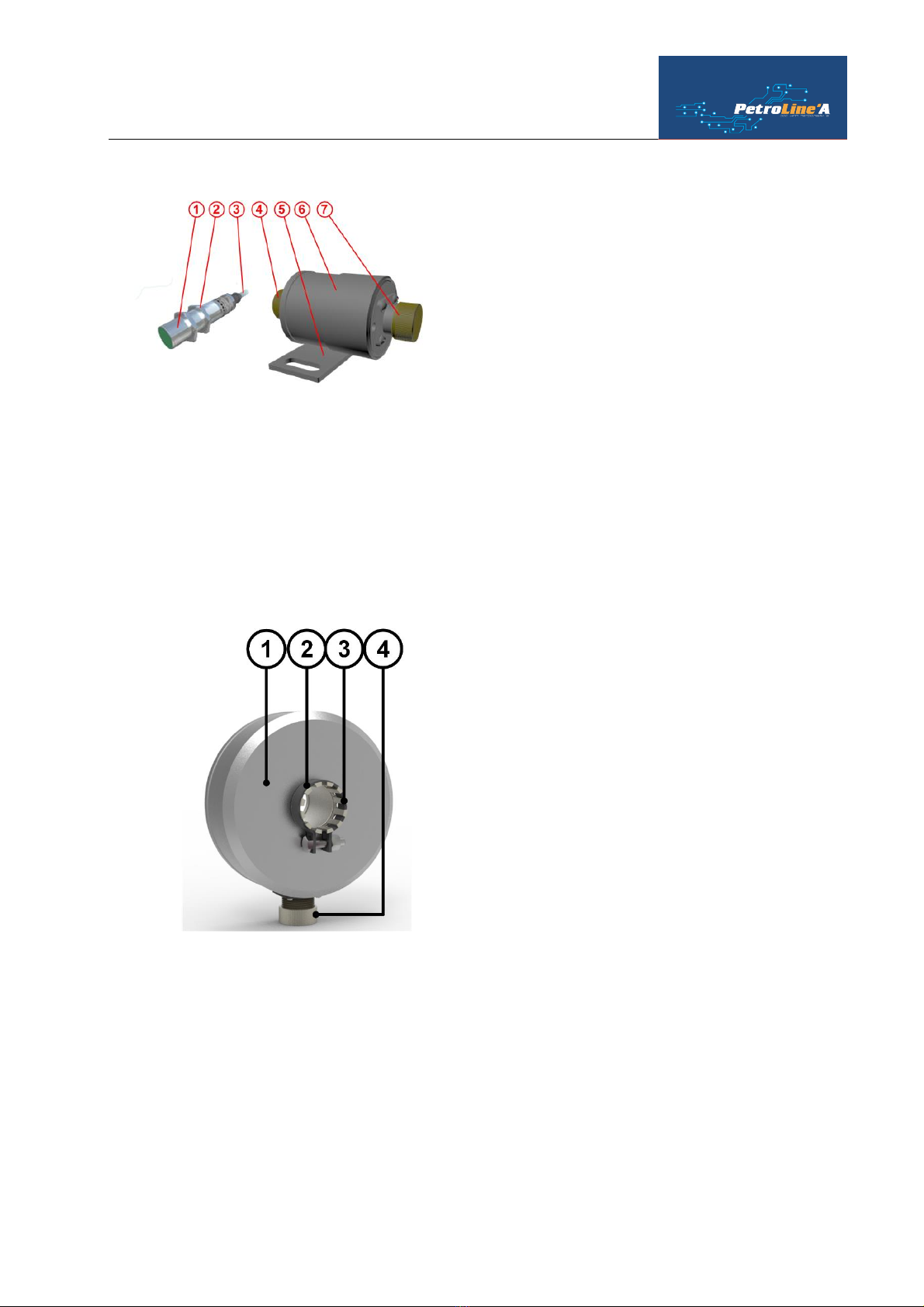

1.1.4. Content DPS-140(E)...................................................................................................................... 6

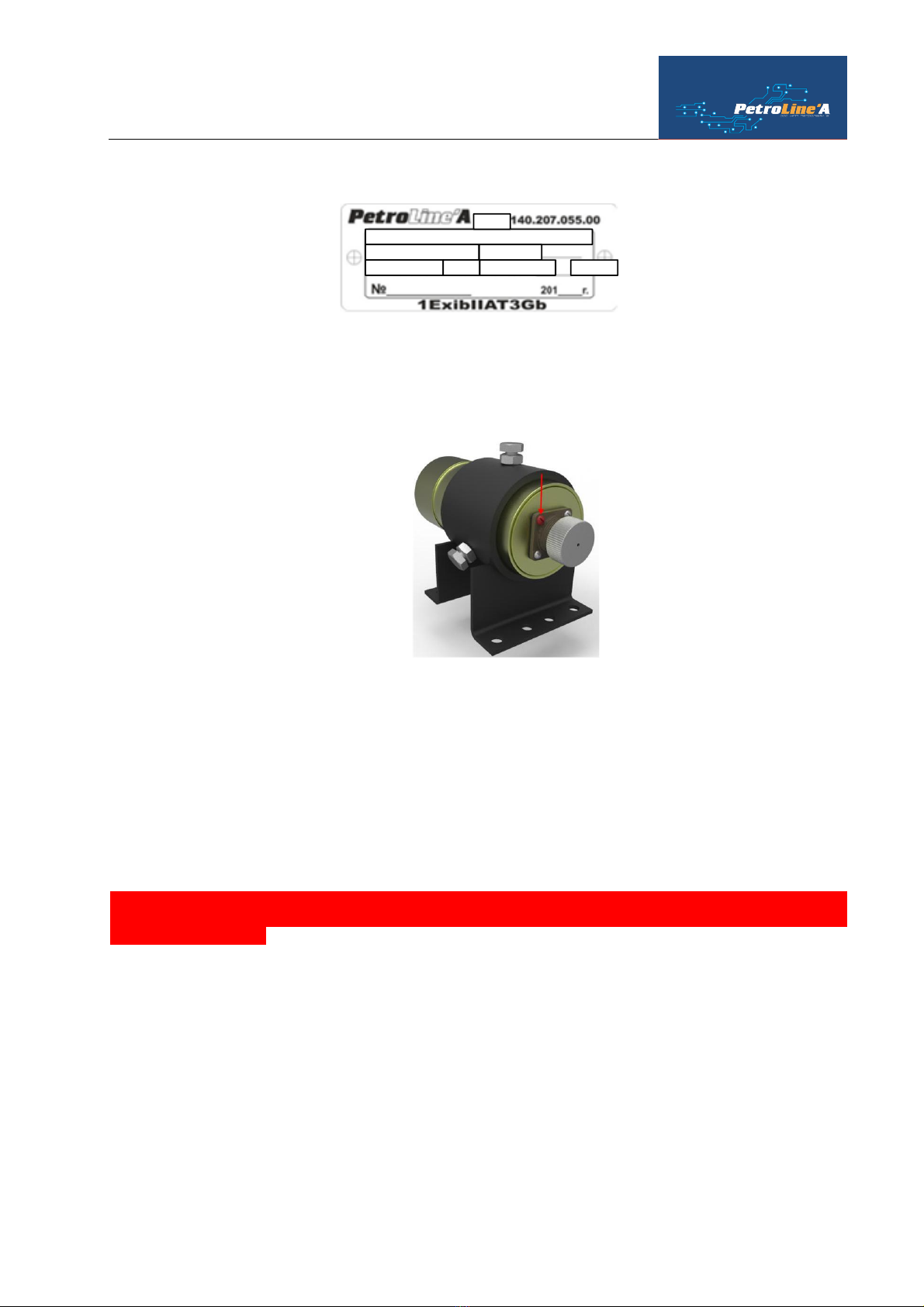

Figure 2 - DPS-140(I)..................................................................................................................................... 7

1.1.5. Content DPS-140(P)....................................................................................................................... 7

Figure 3. DPS-140(P)..................................................................................................................................... 7

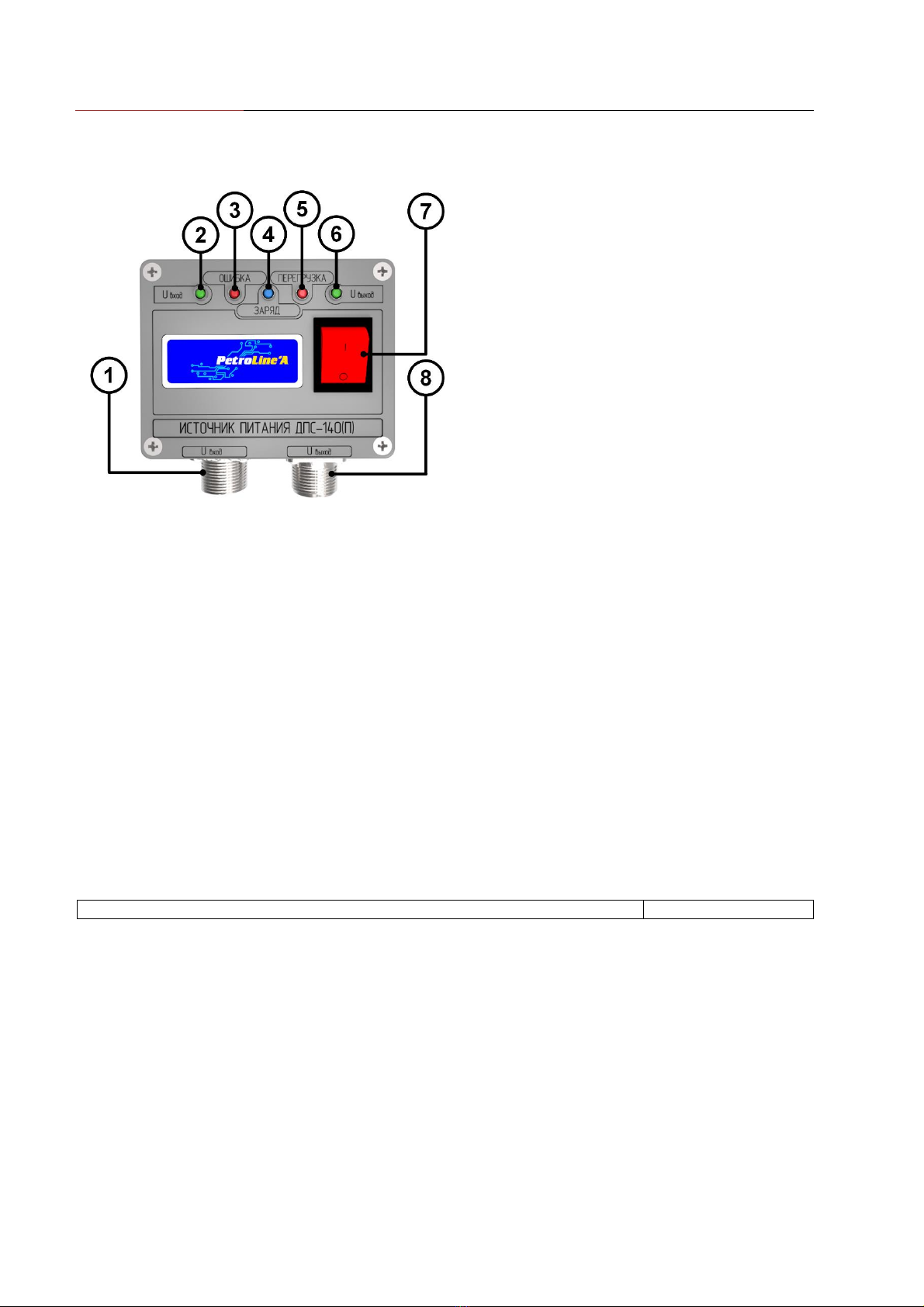

Figure 4. Power Source for DPS-140(P)......................................................................................................... 8

1.1.6. Structure and operationing.............................................................................................................. 8

Table 5 –Ex marking..................................................................................................................................... 8

1.1.9. Marking and sealing....................................................................................................................... 8

Figure 5. Marking examples. .......................................................................................................................... 9

Figure 6. Sealing examples............................................................................................................................. 9

1.1.10. Packaging ...................................................................................................................................... 9

2. Usage............................................................................................................................................................. 9

2.1. Operational constraints............................................................................................................................. 9

2.1.9. Ex rating in operating..................................................................................................................... 9

2.2. Preparation of DPS-140(А,E,I,P) usage ................................................................................................... 10

2.2.1. Volume and sequence of DPS-140 (А,E,I,P)................................................................................. 10

2.2.2. Readiness checking for usage ....................................................................................................... 10

2.2.3. Setting description after preparation for a work:............................................................................ 10

2.2.4. DPS-140(А,E,P) Orientation and indication.................................................................................. 10

Figure 8. DPS-140(А,E) Setting example (at shaft end drawworks)............................................................... 11

Figure 9. DPS-140(P) at drawworks shaft. .................................................................................................... 11

.................................................................................................................................................................... 11

Figure 10. Drawworks shaft-1200................................................................................................................. 12

2.2.5. DPS-140(I) Orientation ................................................................................................................ 12

Figure 11. DPS-140(I) Setting example (at drawworks drum)....................................................................... 12

2.2.6. DPS-140(А,E) Orientation (belt, chain drive)............................................................................... 12

2.2.7. DPS-140(А,E) Orientation (rod).................................................................................................. 12

2.2.9. DPS-140(I) Switch on guideness and parameter setting «TRIPPING RATE» in content of DEL-140.

13

2.2.10. DPS-140(А) Switch on quideness and parameter setting «TRIPPING RATE» in content of DEL-

150. 14

2.2.11. Guideness to parameter setting «TRAVELLING BLOCK POSITION» in content of DEL-150 .... 16

2.2.12. Setting guideness parameter «BIT DEPTH» in content of DEL-150 ............................................. 16

2.2.13. Setting guideness parameter «BIT POSITION» in content of DEL-150....................................... 17

2.2.14. DEL-150 Contractions regarding DPS-140(A) for parameters display on a control module screen. 18

Table 6 –Sensors abbreviations.................................................................................................................... 18