CONTENTS

General information of the machine’s maintenance and

use manual

1

1.1 Introduction 1

1.2 Principal cautions 2

1.3 Safe working practices 4

General information of the instruction manual

5

2.1 Introduction 5

2.2 Rules 5

2.3 Aim of the document 5

2.4 Use and preservation of the manual 6

2.5 Respect of the rules 6

2.6 Preservation of the manual 6

2.7 Information for the user 7

8

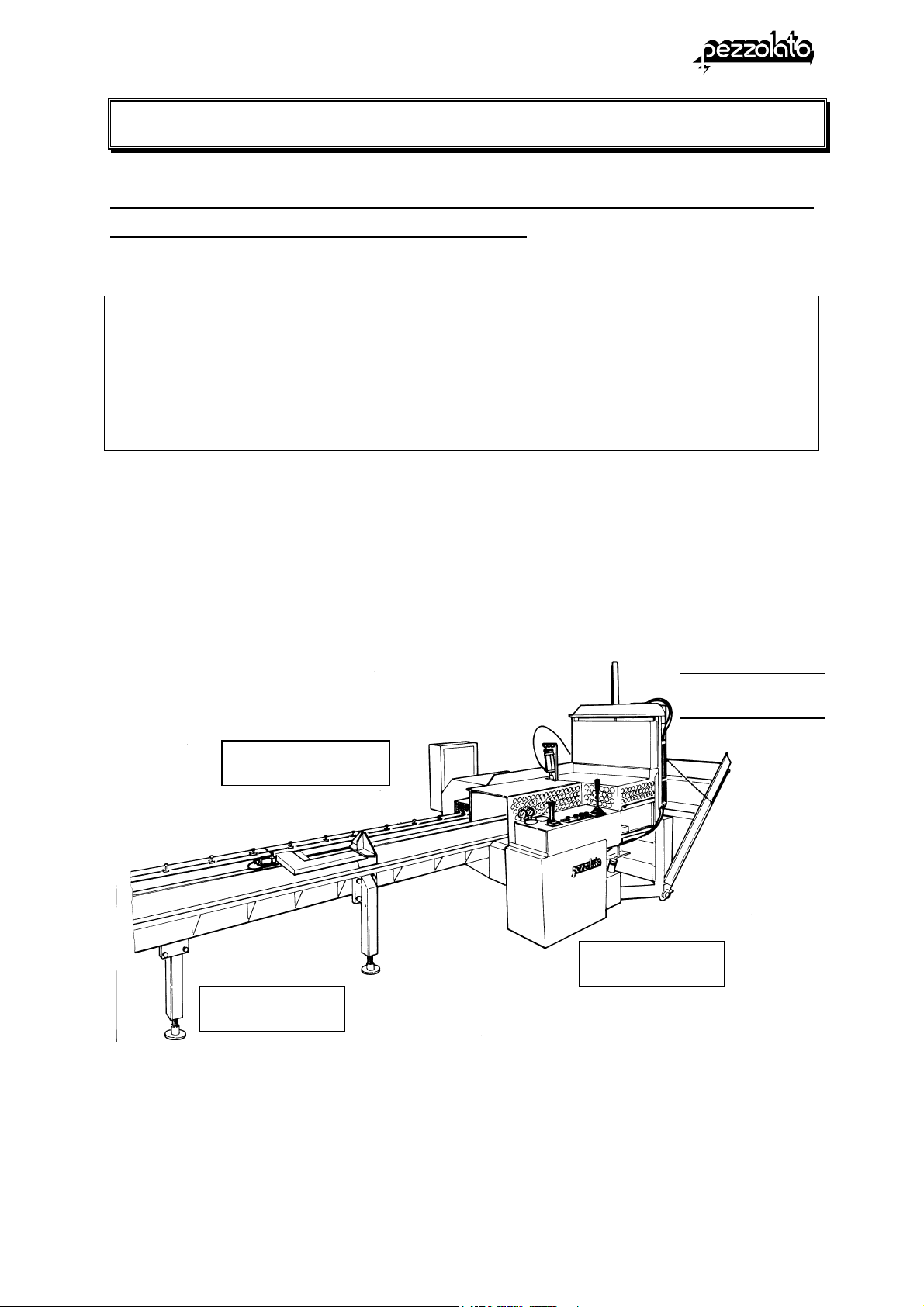

Principal parts of the machine and their positions

9

Safety protections and devices

10

5.1 Fixed front carter 10

5.2 Front door wood-cutter side 10

5.3 Back protections 11

5.4 Emergency push-buttons 11

12

6.1 Considerations about safety conditions and residual

risks

12

14

Installation (PTO version)

Installation (Kombi version) 16

18

8.1 Use of the machine with electric engine 18

8.2 Connection of the compressor 19

8.3 Control of the air plant’s filter-lubricator assembly 19

Installation (version with trolley)

20

8.5 Lubrication of the lay shaft’s supports of the overgear -

pulley

22

8.6 Lubrication of the universal joint of the shaft/pulley 22

8.7 Control and replacement of the overgear’s oil 22

23

9.1 Positioning of the conveyor belt 23

9.2 Adjustment of the conveyor belt tension 23