English Worm gear drive, self-locking 07.02.013

technische Änderungen vorbehalten design changes under reserve changements techniques sous réserve Seite / page 8

!

Inspection- and Maintenance Instructions

Safety Instruction

Before carrying out inspection and maintenance works ensure the winch is unloaded.

Inspection Intervals Maintenance- Inspection Works

Function of the gear.

daily Function of brake (self-locking)

Check the worm gear for wear.

Control lubricant level.

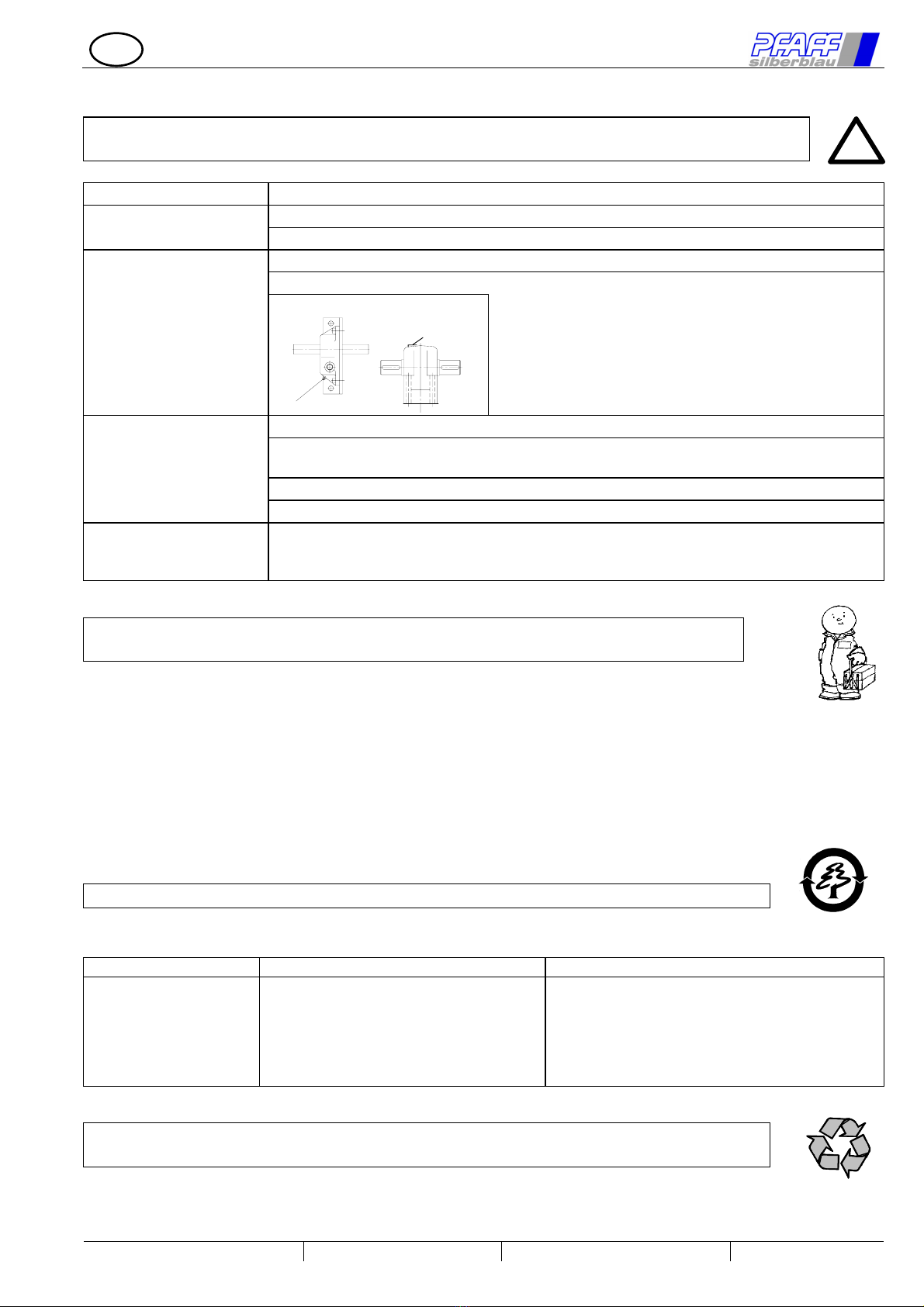

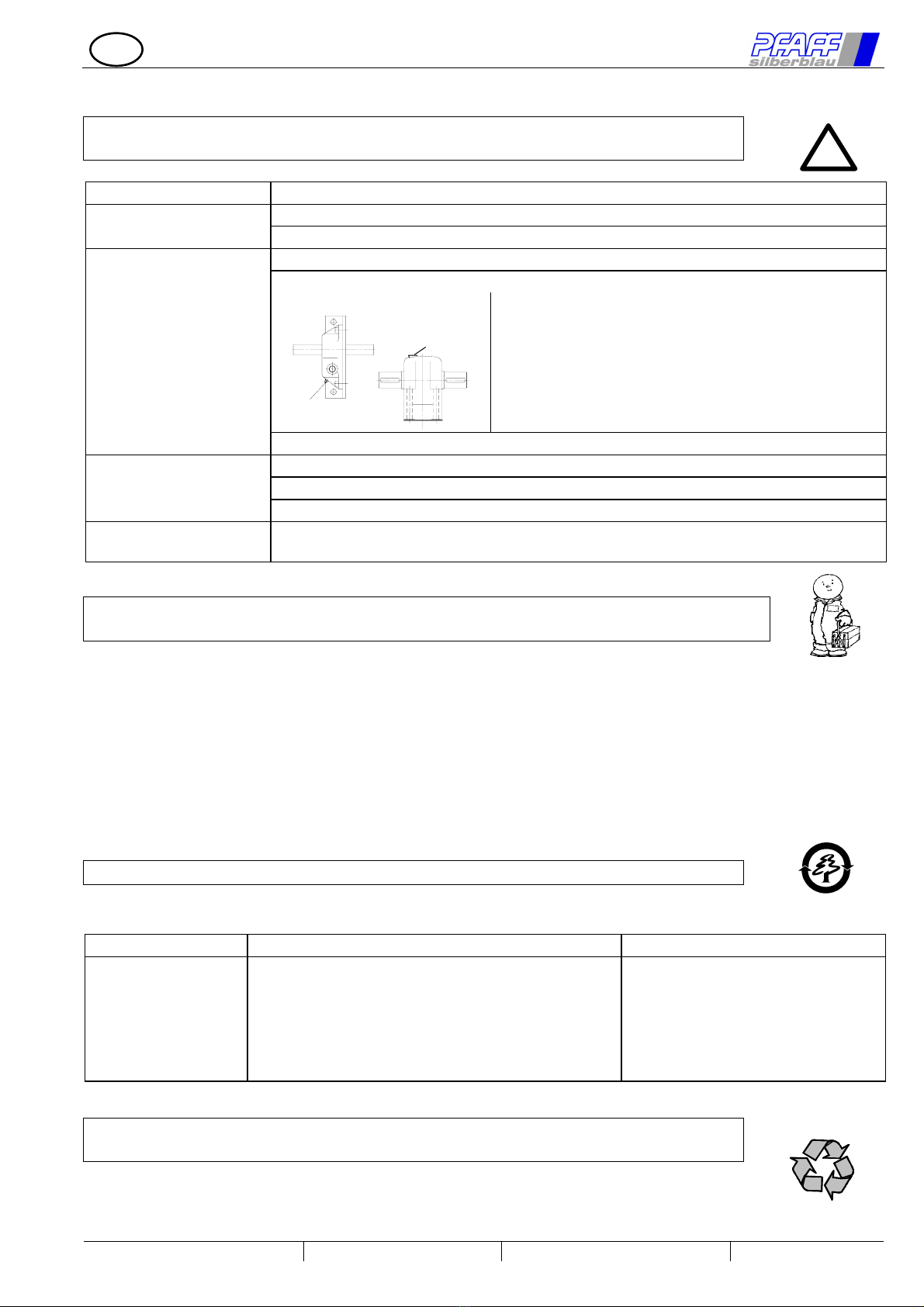

S 20 S 24

lubricating

nipple

plug

S 20-Type 032626004; 032626990

Lubricate the gear box through the lubricating nipple.

S 24-Type 032626020; 032626999

remove the plug, lubricant level and wear are visible.

Afterwards close it.

quarterly

Check the fixing screws for firm seat.

Check all parts of the gear for wear. If necessary, replace defect parts.

Check name plate for legibility

annually

Arrange for an examination by a competent person 1)

every 2 years Replace lubricant. Open the gear, remove the old lubricant refill new lubricant, seal the

housing and re-assemble the gear. Only by authorised personnel 1)

1) for example by Pfaff-silberblau service department.

The working life of the winch is limited, wearing parts have to be replaced in good

time.

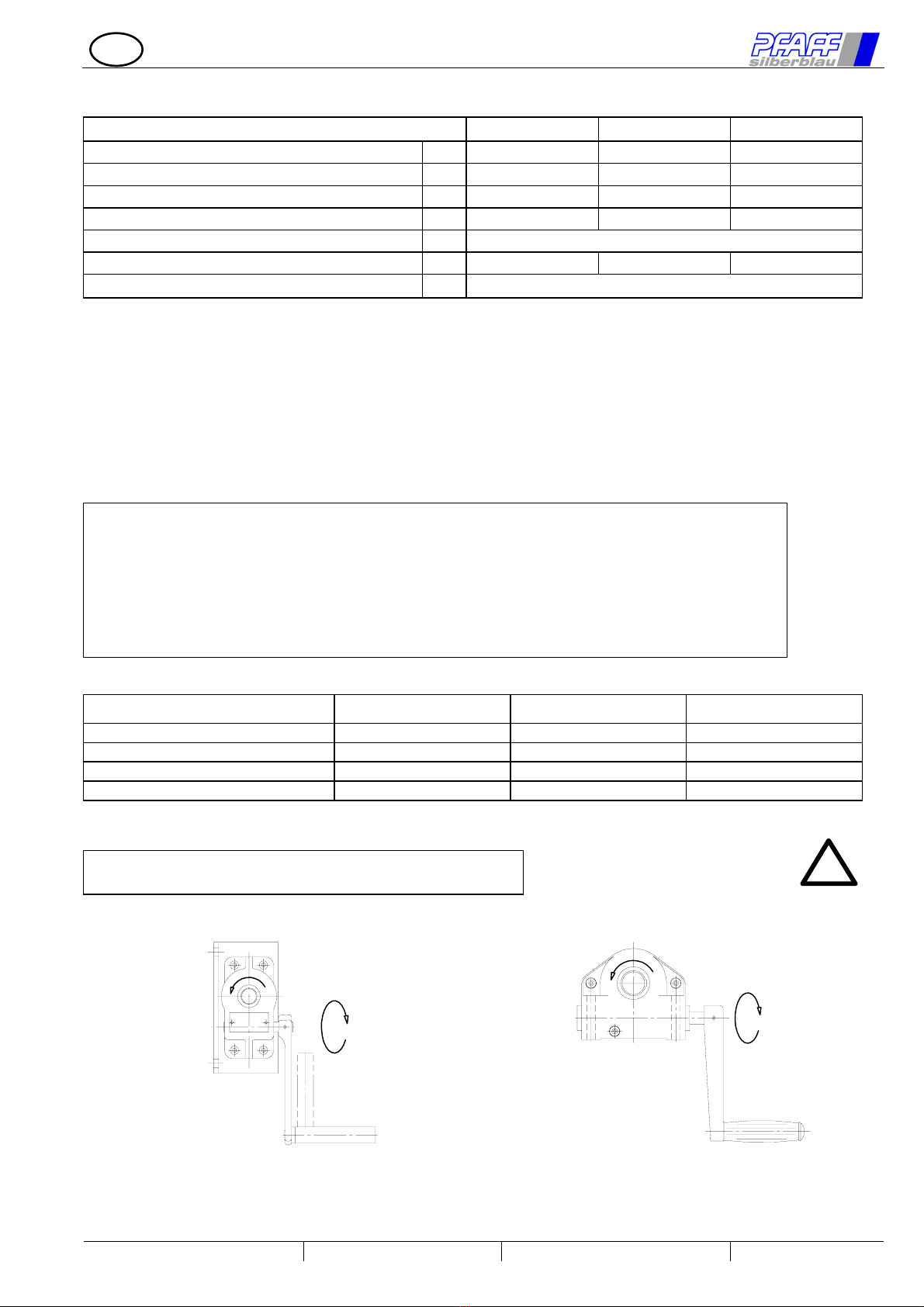

Betriebsstoffe / Schmierstoffempfehlung

recommended lubricant for all greasing points:

Gear S 20 - Type 032626004; 032626 990

multipurpose grease according to DIN 51825 T1 K2K

Gear S 24 - Type 032626 020; 032626 999

lubricating grease DIN 51826 (DIN 51502) GPOH

lubricant quantity:200 cm³

e.g.: ESSO-Fibrax EP 370 or any grease equal quality

Waste lubricant has to be disposed according to legal regulations!

Operating failures and their causes

Failure Cause Elimination

In unloaded state, it is

difficult to turn the

crank.

Lubricant in bearing points and gearing is missing.

Dirt or something similar has accumulated in the

gearing.

Gear was distorted during mounting.

Execute maintenance works.

Check the fixing.

Is the mounting surface even, are

the screws tightened correctly?

Disposal

After having placed out of service, the parts of the hand operated gear box have

to be recycled or disposed according to legal regulations!