6.

Threading

ihe

Bobbin

Case

Insert

the

full

bobbin

into

the

bobbin

case

cover

so

that

the

thread

un

winds

clockwise

(Photo 5).

Pull

the

thread

into the slot 1,

and

draw

it under the tension spring into

the delivery

eye

2. Place the bobbin

case

cover with the bobbin on the

center

stud

in the

bobbin

case

base

so

that

the

bobbin

case

latch

points

toward

the

operator.

Press the

bobbin

case

in until it clicks in position

audibly. This is very innportant

as

otherwise

needle or

bobbin

case

breakage

may

result.

Photo

5

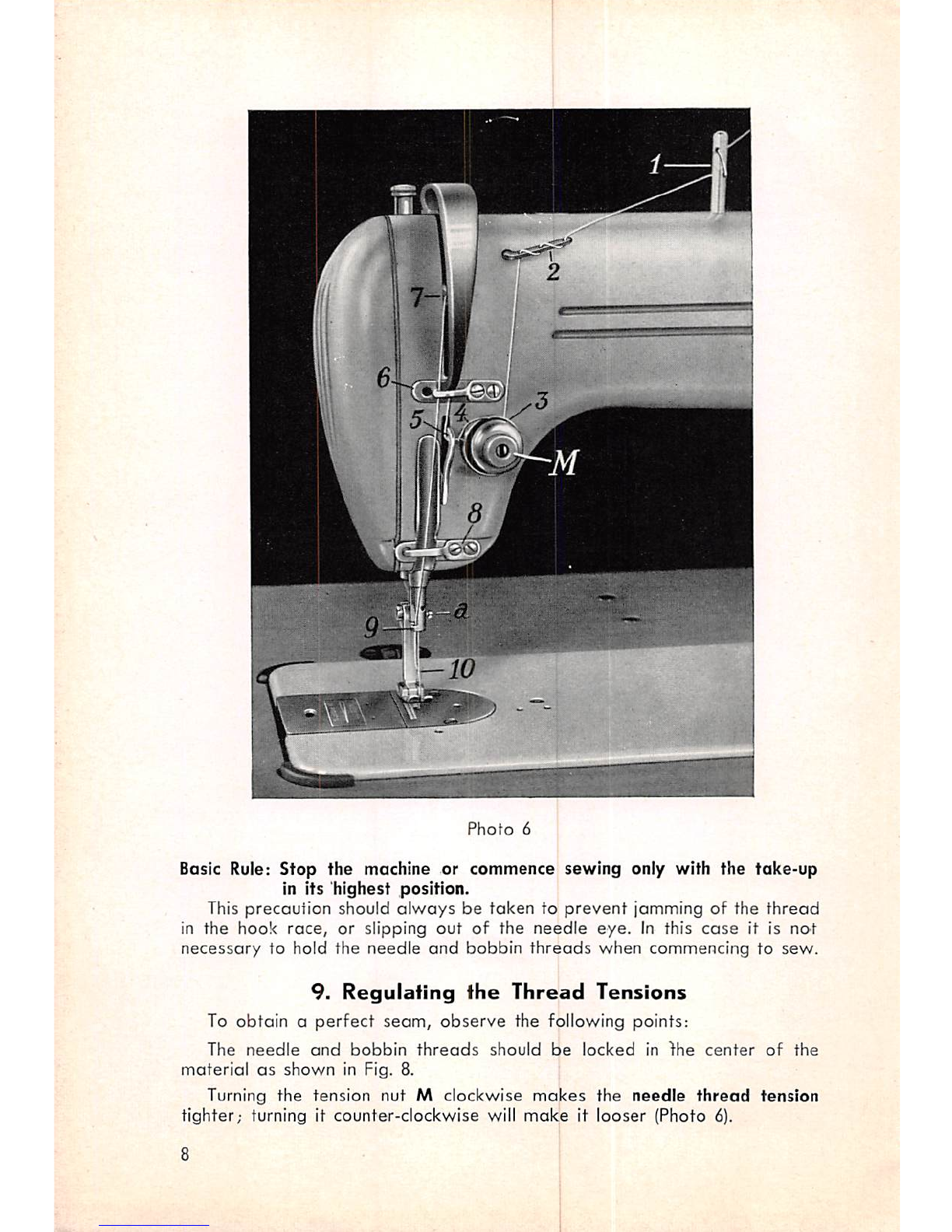

7.

Threading

fhe

Needle

Threading the

PFAFF

436

presents no difficulty since the thread, as with

PFAFF

133/134

machines, passes in plain view of the operator (Photo 6) so

that every user should be familiar with it. Pass the thread from the thread

unwinder to thread guide pin 1 and, to prevent vibration of the thread

at

high

speed,

through

both of its holes.

By

the same token, pass it

through

all

three

holes in fhe

thread

retainer

2

as

shown

in

photo

6,

and

then

be

tween tension discs 3, to threod check spring 4, below guide 5, through

guide 6, right-left through the take-up eyelet 7, down to thread guide 8 and

needle

bar

eyelet

9, and left-right through the needle

eye

10.

8.

Drawing

Up

the

Bobbin

Thread

Hold

the

end

of

the

needle

thread,

and

turn

the

balance

wheel

toward

you

until

the needle moves down and up again, thus catching the bobbin

thread which comes up through the needle hole in a loop (Photo 7). Place

both

threads

back

under the

presser

foot.