Contents

Contents ................................................................................. Chapter - Page

1Safety ........................................................................................................................... 1 - 1

1.01 Regulations ................................................................................................................... 1 - 1

1.02 General notes on safety ................................................................................................ 1 - 1

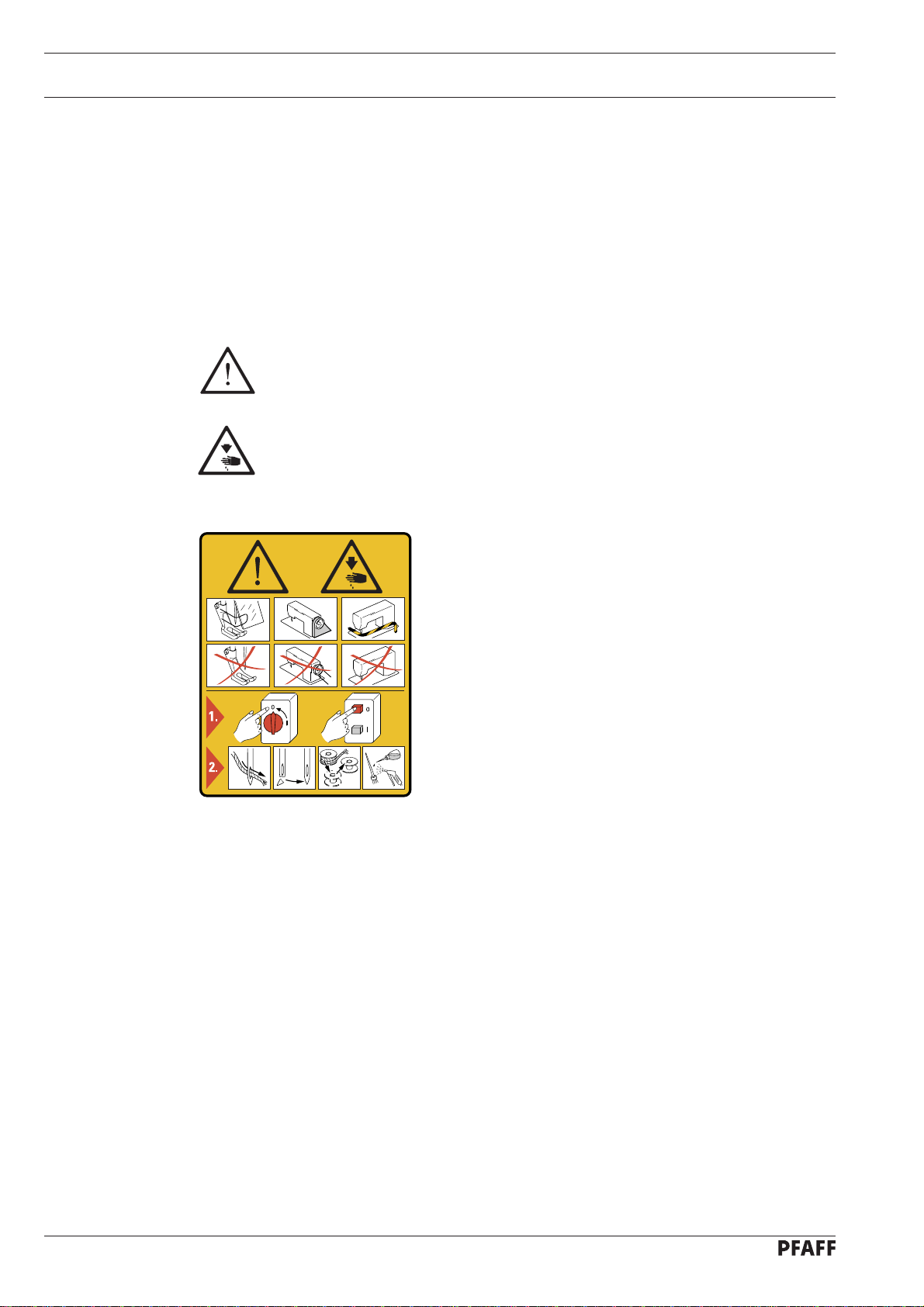

1.03 Safety symbols ............................................................................................................. 1 -2

1.04 Important notes for the user ......................................................................................... 1 - 2

1.05 Notes for operating and technical staff ......................................................................... 1 - 3

1.05.01 Operating staff .............................................................................................................. 1 - 3

1.05.02 Technical staff............................................................................................................... 1 - 3

1.06 Danger warnings........................................................................................................... 1 - 4

2Proper use.................................................................................................................... 2 -1

3Specifications .............................................................................................................. 3 - 1

3.01 General specifications ................................................................................................... 3 - 1

3.02 Specifications of the PFAFF 5704 ................................................................................. 3 - 2

3.03 Specifications of the PFAFF 5714 ................................................................................. 3 - 2

3.04 Specifications of the PFAFF 5716 ................................................................................. 3 - 3

3.05 Specifications of the PFAFF 5742 ................................................................................. 3 - 3

4Disposal of the machine ............................................................................................. 4 - 1

5Transport, packaging and storage ............................................................................. 5 - 1

5.01 Transport to the customer ............................................................................................ 5 - 1

5.02 Transport within the customer’s premises ................................................................... 5 - 1

5.03 Disposal of the packaging ............................................................................................. 5 - 1

5.04 Storage ......................................................................................................................... 5 - 1

6Explanation of the symbols........................................................................................ 6 - 1

7Control elements ......................................................................................................... 7 - 1

7.01 Main switch ..................................................................................................................7- 1

7.02 Pedal ............................................................................................................................. 7 - 1

7.03 Balance wheel............................................................................................................... 7- 2

7.04 Sewing foot retracting lever .......................................................................................... 7 - 2

7.05 Cloth plate stop lever .................................................................................................... 7 - 3

7.06 Stop button for stitch length adjustment....................................................................... 7 - 3

7.07 Lever for setting the fullness ........................................................................................ 7 - 4

8Mounting and commissioning the machine ............................................................. 8 - 1

8.01 Installation..................................................................................................................... 8 - 1

8.01.01 Adjusting the table height ............................................................................................. 8 - 1

8.01.02 Table top drill hole plans (for mid-height assembly)....................................................... 8 - 2

8.01.03 Table top cut-out (for mid-height assembly) .................................................................. 8 - 3

8.01.04 Sewing head support plate (for mid-height assembly) .................................................. 8 - 4

8.01.05 Table top drill hole plans (for assembly level with the table top) ................................... 8 - 5

8.01.06 Table top cut-out (for assembly level with the table top)............................................... 8 - 6