Contents ..................................................................................Page

Contents

3

1Safety .................................................................................................................................... 5

1.01 Directives............................................................................................................................... 5

1.02 General notes on safety......................................................................................................... 5

1.03 Safety symbols ...................................................................................................................... 6

1.04 Important notes for the user.................................................................................................. 6

1.05 Operating and technical staff ................................................................................................. 7

1.05.01 Operating staff ....................................................................................................................... 7

1.05.02 Technical staff ........................................................................................................................ 7

1.06 Danger ................................................................................................................................... 8

2Proper use............................................................................................................................. 9

3Specifications ..................................................................................................................... 10

4Disposal of Machine ...........................................................................................................11

5Transportation, packing and storage ................................................................................ 12

5.01 Transportation to customer‘s premises ............................................................................... 12

5.02 Transportation inside the customer‘s premises................................................................... 12

5.03 Disposal of packing materials ..............................................................................................12

5.04 Storage ................................................................................................................................ 12

6Explanation of symbols..................................................................................................... 13

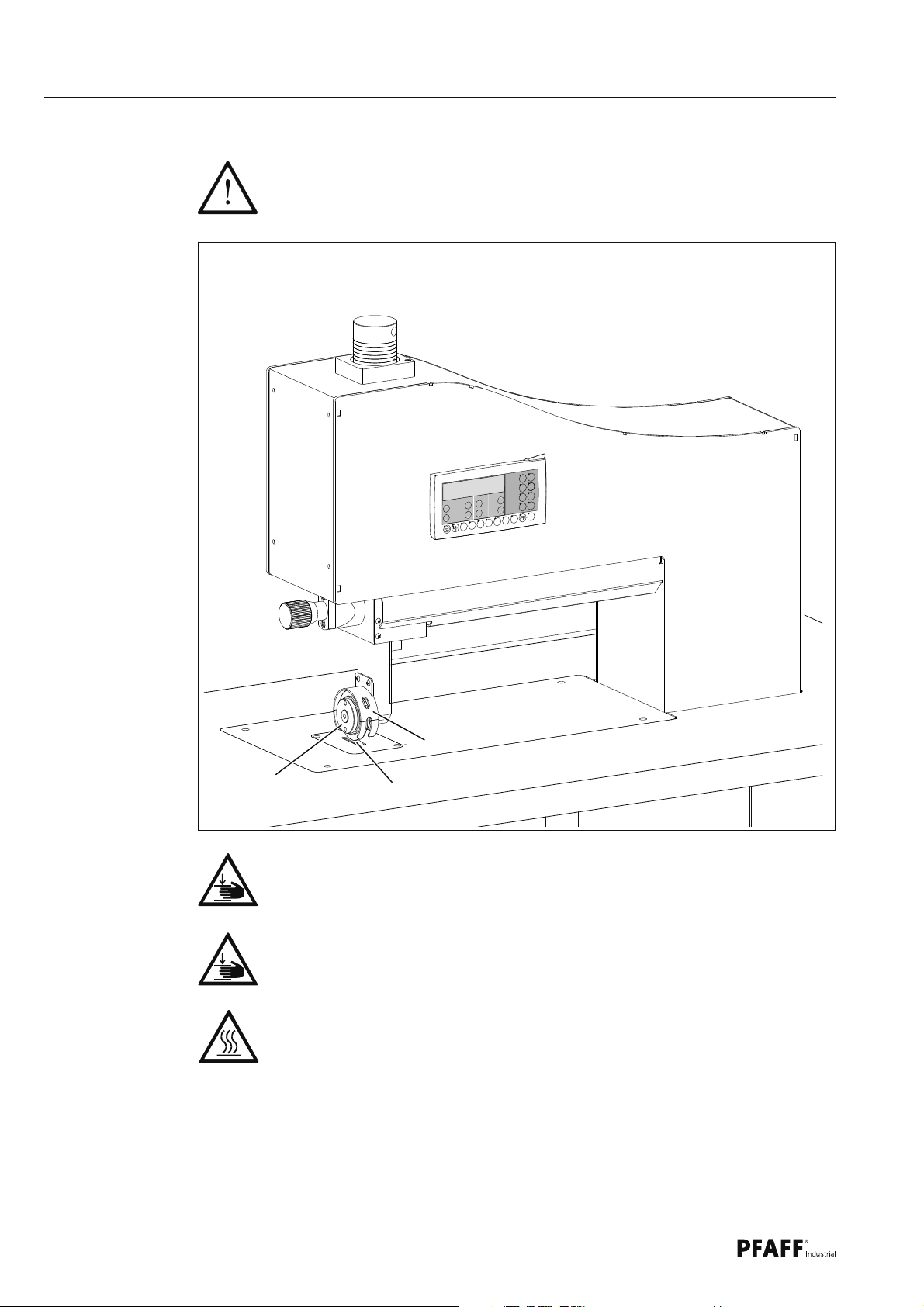

7Controls .............................................................................................................................. 14

7.01 Summary of control elements ............................................................................................. 14

7.02 Main switch ......................................................................................................................... 15

7.03 Pedal .................................................................................................................................... 15

7.04 Setting wheel for roller distance ..........................................................................................16

7.05 Setting wheel for roller pressure.......................................................................................... 16

7.06 Control panel........................................................................................................................ 17

7.06.01 Symbols on the display ........................................................................................................ 17

7.06.02 Function keys ....................................................................................................................... 18

8Installation and commissioning ....................................................................................... 19

8.01 Installation............................................................................................................................ 19

8.01 Adjusting the table-top height.............................................................................................. 19

8.02 Commissioning .................................................................................................................... 20

8.03 Switching the machine on/off ..............................................................................................20

9Preparation ......................................................................................................................... 21

9.01 Programme call-up and modification.................................................................................... 21

9.02 Setting roller distance and roller pressure ........................................................................... 21

9.03 Setting the differential transport .......................................................................................... 22

9.04 Additional transport rollers (optional) ................................................................................... 22

9.05 Inserting and removing the SD-memory card...................................................................... 23

10 Sealing ................................................................................................................................ 24

10.01 Sealing principle .................................................................................................................. 24

10.02 Error messages.................................................................................................................... 25