Index

Contents ..................................................................................Page

1 Proper use ..........................................................................................................................4

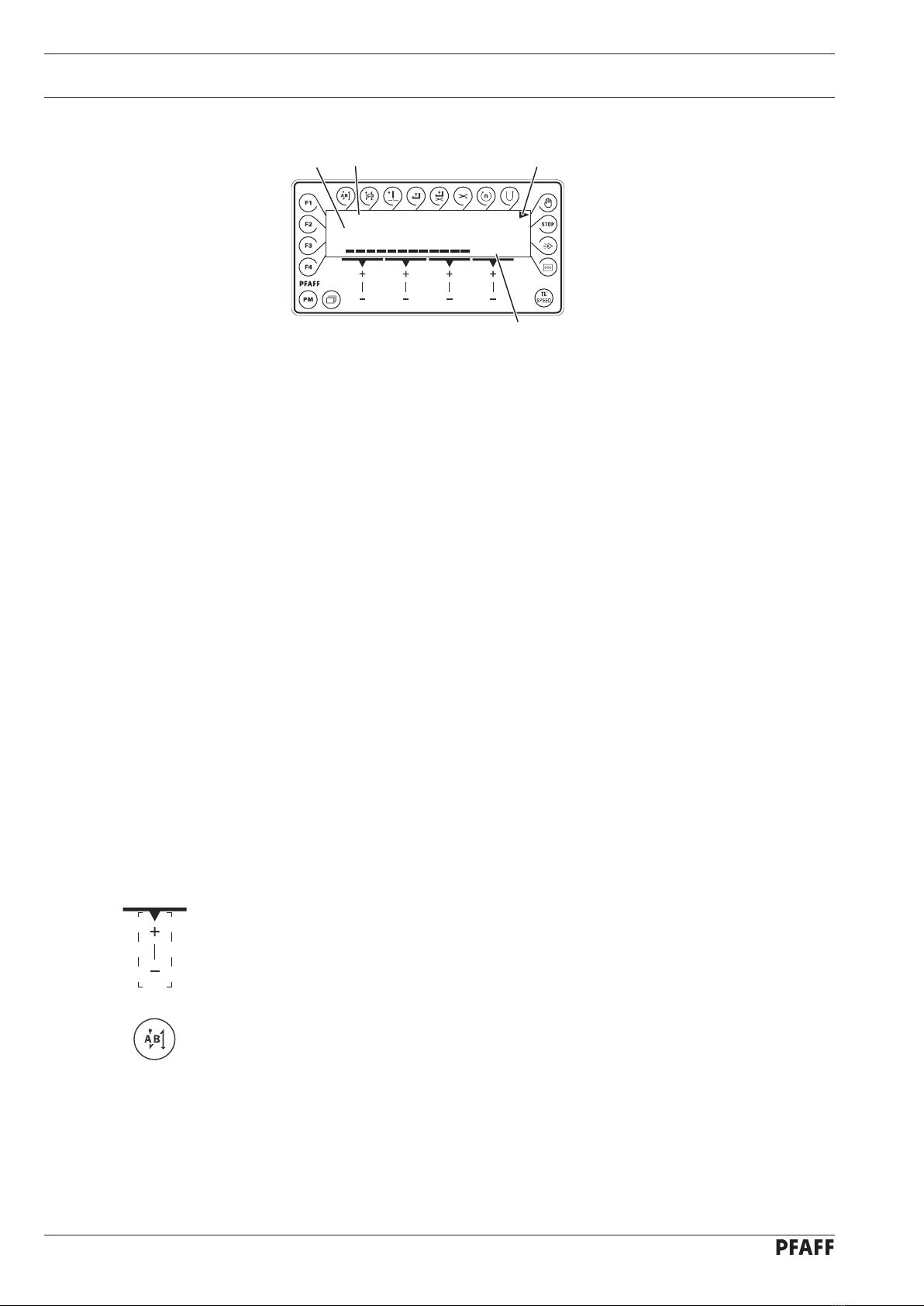

2 Controls ................................................................................................................................5

2.01 Knee switch .......................................................................................................................... 5

2.02 Control panel .......................................................................................................................... 6

2.02.01 Screen displays ...................................................................................................................... 6

2.02.02 Function keys ......................................................................................................................... 6

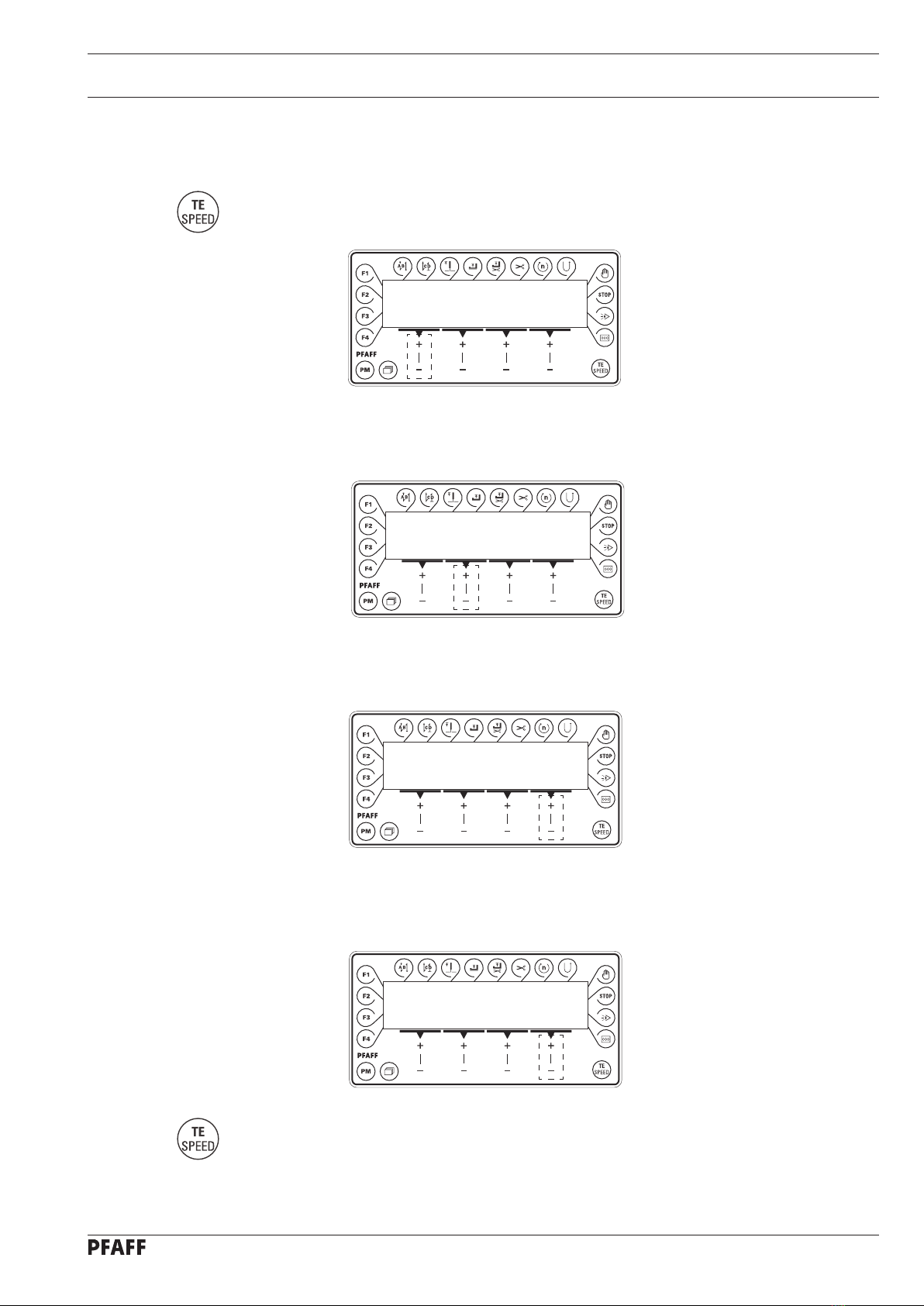

2.02.03 Selecting and altering parameters ......................................................................................... 9

2.02.04 Selecting the user level ........................................................................................................ 10

3 Commissioning .................................................................................................................. 11

3.01 Basic position of the machine drive ..................................................................................... 11

3.02 Testing the function of the start inhibitor ............................................................................. 12

4 Setting up ........................................................................................................................... 13

4.01 Entering the maximum speed ............................................................................................. 13

4.02 Setting the presser foot pressure ........................................................................................ 13

4.03 Entering the start and end backtacks ................................................................................... 14

4.04 Setting the stitch counting function for the bobbin thread control ...................................... 15

5 Sewing ................................................................................................................................ 16

5.01 Manual sewing .................................................................................................................... 16

5.02 Programmed sewing ............................................................................................................ 17

5.03 Error messages .................................................................................................................... 18

6 Parameter Settings ............................................................................................................. 19

7 Internet update of the machine software ......................................................................... 20

8 Reset / Cold start ................................................................................................................ 21

9 Parts list ............................................................................................................................. 22

10 Circuit diagrams .................................................................................................................23