Contents

Contents ................................................................................. Chapter - Page

13 Adjustment ................................................................................................................ 13 - 1

13.01 Notes on adjustment................................................................................................... 13 - 1

13.02 Tools, gauges and other accessories .......................................................................... 13 - 1

13.03 Abbreviations .............................................................................................................. 13- 1

13.04 Adjusting the basic machine ....................................................................................... 13 - 2

13.04.01 Pre-adjusting the needle height................................................................................... 13 - 2

13.04.02 Setting the bottom feed dog at its neutral position ..................................................... 13 - 3

13.04.03 Bottom feed dog motion............................................................................................ 13 - 4

13.04.04 Bottom feed dog position............................................................................................ 13 - 5

13.04.05 Needle rise, hook clearance, needle height and bobbin case position finger............... 13 - 6

13.04.06 Thread check spring and thread regulator ................................................................... 13 - 7

13.04.07 Knee lever stop ...........................................................................................................13- 8

13.04.08 Presser foot pressure ................................................................................................. 13 - 9

13.05 Adjusting the thread trimmer –900/93......................................................................... 13 -10

13.05.01 Adjusting the synchronizer.......................................................................................... 13 -10

13.05.02 Adjusting the control cam ........................................................................................... 13 -11

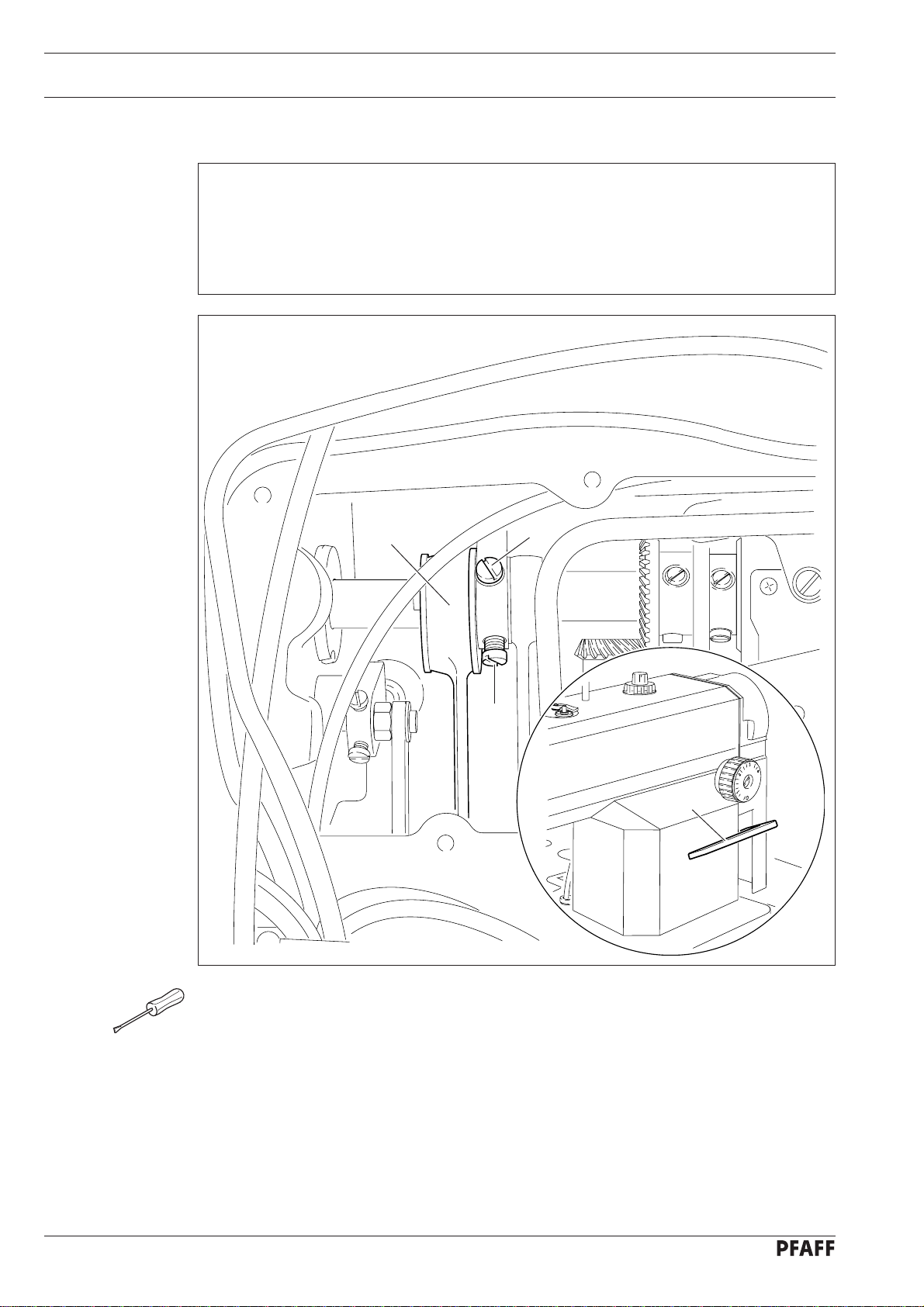

13.05.03 Position of the stationary knife.................................................................................... 13 -12

13.05.04 Needle thread tension release .................................................................................... 13 -13

13.06 Adjusting the thread wiper –909/93 ............................................................................ 13 -14

13.07 Adjusting the automatic presser foot lift –910/93........................................................ 13 -15

13.08 Adjusting the backtacking mechanism –911/93 .......................................................... 13 -16

13.09 Parameter settings...................................................................................................... 13 -17