1

Page

Table of contents 1

Foreword 3

Notes on the sewing machine 4

Specifications of the coverlock 4772 5

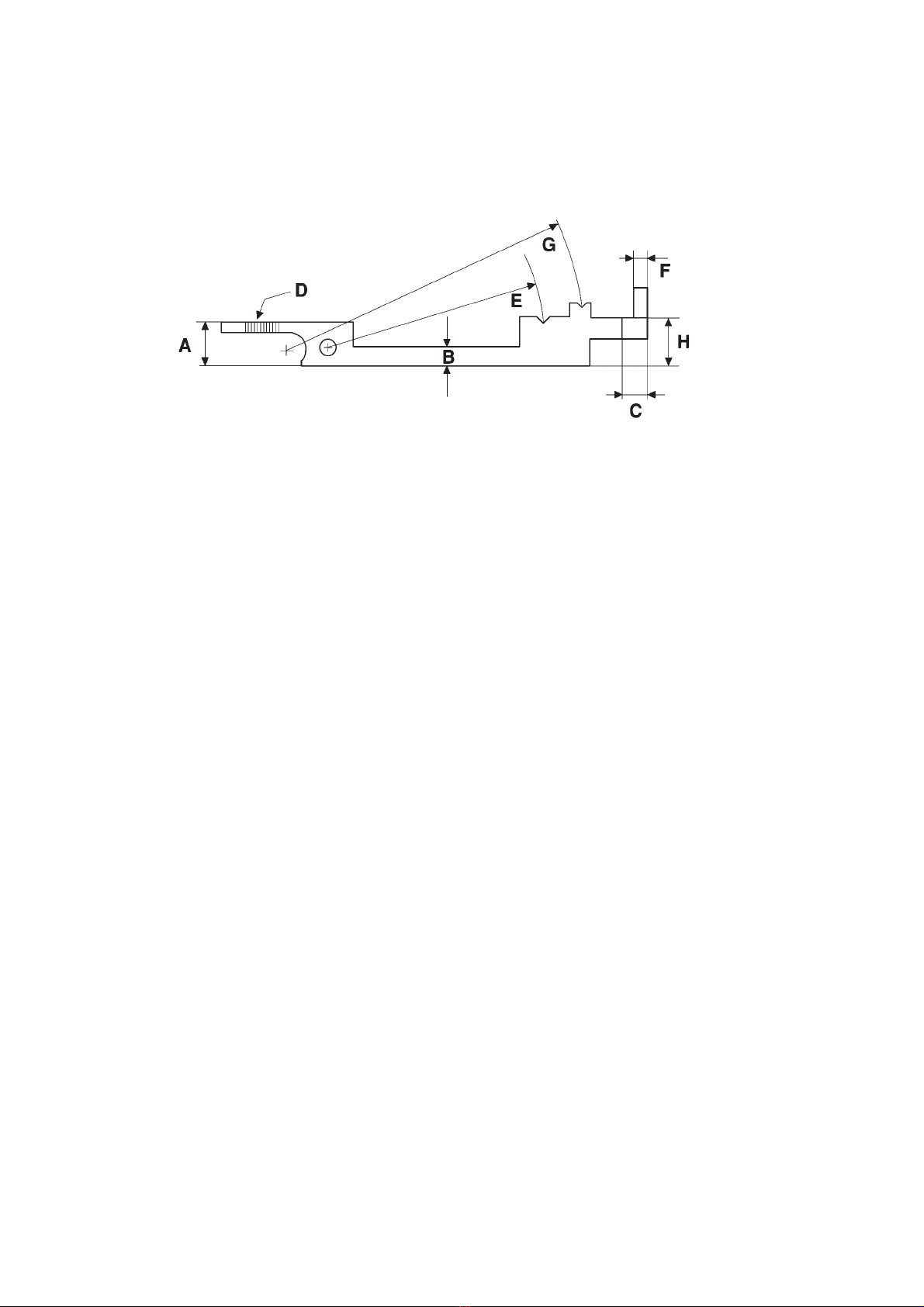

Adjustment gauge of the coverlock 4772 6

Dismantling the housing of the coverlock 4772 7

Requirements for adjusting the coverlock 4772 11

Needle bar height and needle penetration points

1. Setting the needle bar height 14

2. Setting the needle penetration points 15

Feeding system

3. Setting the main feed dog in the sewing direction with regard to the needle plate 16

4. Setting the feed dog movement 18

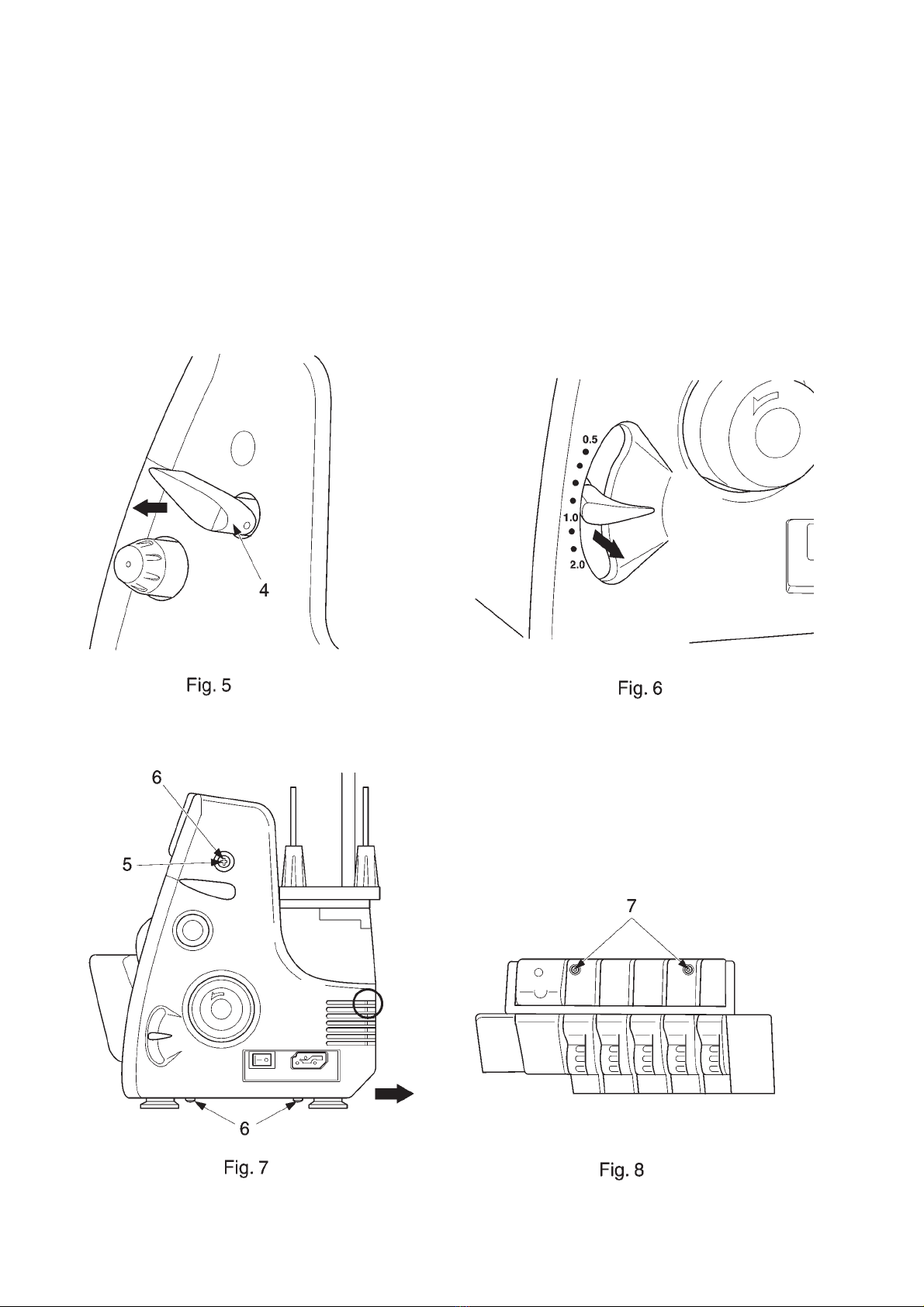

5. Setting the stitch length 20

6. Setting the stitch length adjustment knob 21

7. Setting the differential feed dog 22

8. Setting the differential feed-dog height 23

9. Setting the presser bar height 24

10. Setting the presser bar eccentrics 25

Setting the lower overedge looper

11. Setting the height of the lower overedge looper 27

12. Setting the timing of the lower overedge looper 28

13. Setting the looper-to-needle clearance 30

14. Setting the lateral clearance to the right needle 32

Setting the upper overedge looper

15. Setting the height of the overedge looper 33

16. Setting the lateral clearance to the right needle 34

17. Setting the timing of the upper overedge looper 35

18. Setting the clearance between the upper and lower overedge looper 36

Setting the two thread chainstitch looper

19. Setting the height of the two thread chainstitch looper 37

20. Setting the lateral clearance to the cover stitch needle (D) 38

21. Setting the looper-to-needle clearance 39

22. Setting the timing of the two thread chainstitch looper 40

Setting the needle guards

23. Setting the rear needle guard 42

24. Setting the front needle guard 43

25. Setting the needle guard for the cover stitch needles 44

Setting the upper and lower blades

26. Setting the lower blade 45

27. Setting the upper blade 46

28. Setting the lower blade bracket 47

29. Setting the chaining finger 48

Setting the looper thread guides

30. Setting the looper thread guide of the lower overedge looper 49

31. Setting the looper thread guide of the upper overedge looper 49

32. Setting the looper thread guides of the two thread chainstitch looper 50