1

Contents 1

Foreword 3

Notes on the sewing machine in relation to environment, handling, cleaning and safety 5

Specifications off PFAFF machines 6

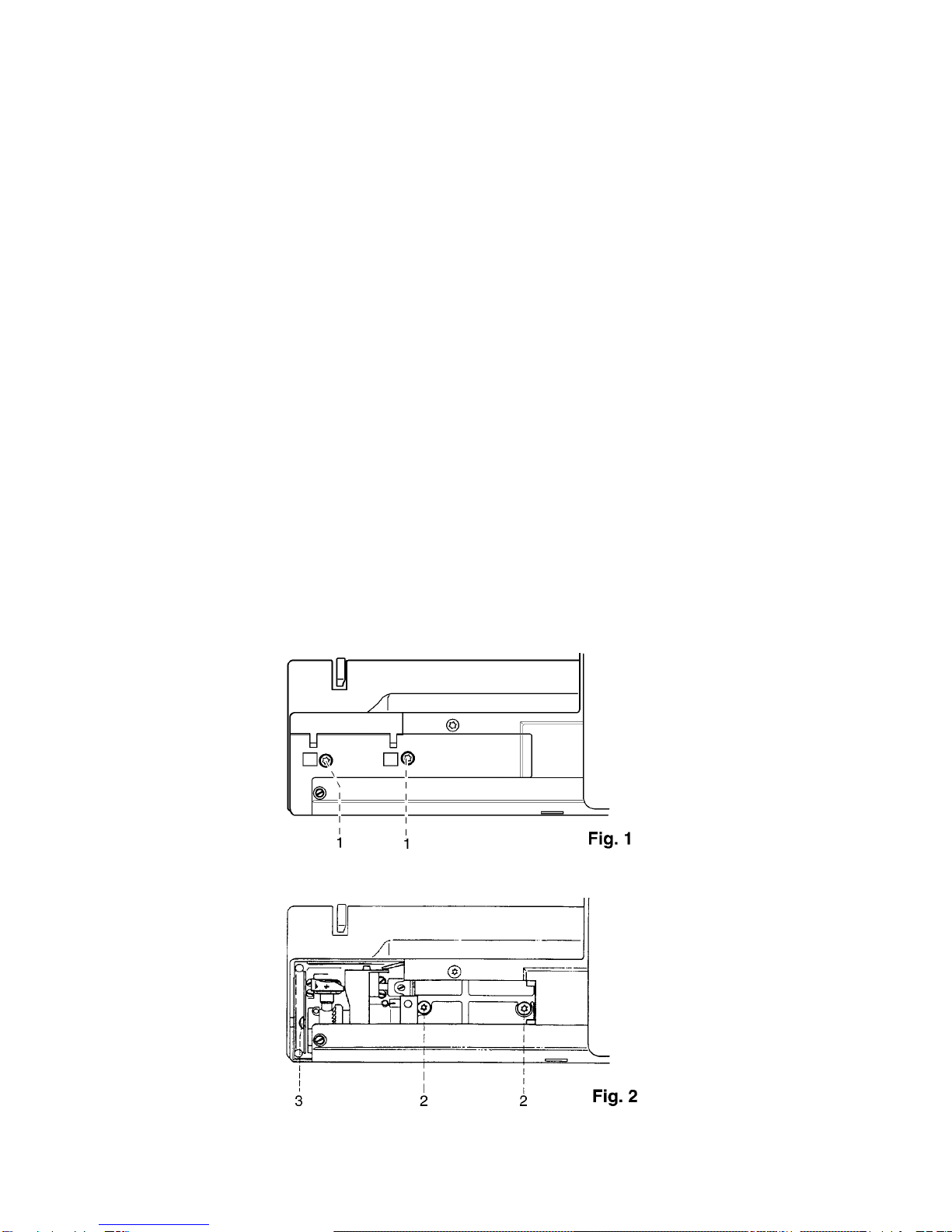

Removing the housing covers 8

Adjustment instructions

Feeding system

1. Adjustment of toothed belt tension 13

2. Adjustment of feed dog in sideways direction on Pfaff 1520 14

3. Adjustment of feed dog in sideways direction on Pfaff 1530-1540 16

4. Adjustment of feed dog height 18

5. Adjustment of presser bar height on Pfaff 1520 19

6. Adjustment of presser bar height on Pfaff 1530-1540 20

7. Adjustment of top feed foot in sewing direction 22

8. Adjustment of top feed foot height 24

9. Adjustment of feed regulator cranks on Pfaff 1520 / 1530 26

10. Adjustment of feed regulator cranks on Pfaff 1540 27

11. Zero point adjustment of stitch length regulator 28

12. Timing of feed motion 30

Automatic utility-stitch unit

13. Replacing the automatic module on Pfaff 1520 - 1530 32

14. Adjustment of the locking disk 34

15. Replacing the zigzag-stitch unit on Pfaff 1520 - 1530 35

16. Basic position of setting eccentric for the sideways needle position 36

17. Adjustment of needle penetration in needle plate slot 37

18. Adjustment of the sideways movement of the needle bar 38

19. Adjustment of the stop for the left needle position 40

20. Adjustment of the feed reversing bar 42

21. Replacing the utility-stitch unit on Pfaff 1540 44

22. Adjustment of the gears in relation to each other 46

23. Replacing the zigzag-stitch unit on Pfaff 1540 47

24. Basic position of setting eccentric for the sideways needle position on Pfaff 1540 48

25. Adjustment of needle penetration in needle plate slot on Pfaff 1540 49

26. Adjustment of the sideways movement of the needle bar on Pfaff 1540 50

27. Adjustment of zigzag stitch penetration in needle plate slot on Pfaff 1540 52

28. Adjustment of the stop for the left needle position on Pfaff 1540 53

Stitch forming parts (sewing hook)

29. Adjustment of needle clearance in needle slot in sewing direction 56

30. Adjustment of hook-to-needle clearance 58

30a. Adjustment of bevel gears 59

31. Sewing hook timing 60

32. Adjustment of needle bar height 62

33. Adjustment of bobbin case position finger 63

Page