Contents

Contents ................................................................................. Chapter - Page

1Safety ............................................................................................................................ 1 - 1

1.01 Regulations ................................................................................................................... 1 - 1

1.02 General notes on safety ................................................................................................. 1 - 1

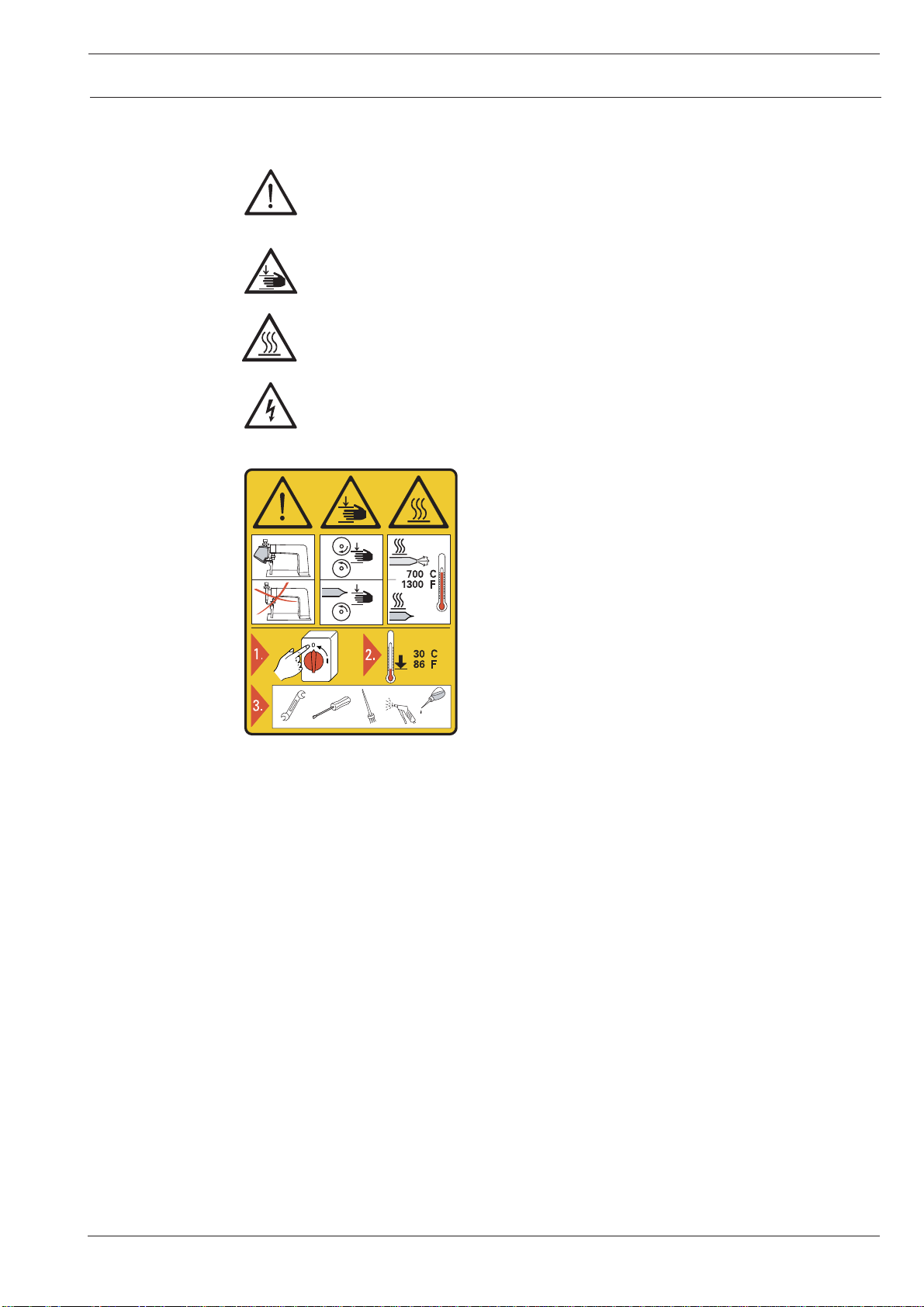

1.03 Safety symbols ............................................................................................................. 1 -2

1.04 Important points for the user.......................................................................................... 1 - 2

1.05 Operating and technical personnel ................................................................................. 1 - 3

1.05.01 Operatingpersonnel ....................................................................................................... 1 - 3

1.05.02 Technicalpersonnel ....................................................................................................... 1 - 3

1.06 Dangerwarning ............................................................................................................. 1 -4

2Proper use .................................................................................................................... 2 -1

3Specifications .............................................................................................................. 3 - 1

4Disposal of the machine .............................................................................................. 4 - 1

5Transport, packing and storage .................................................................................. 5 - 1

5.01 Transport to the customer’s premises ........................................................................... 5 - 1

5.02 Transport within the customer’s premises ..................................................................... 5 - 1

5.03 Disposal of packing ....................................................................................................... 5 - 1

5.04 Storage .......................................................................................................................... 5 - 1

6Explanation of the symbols ........................................................................................ 6 - 1

7Controls........................................................................................................................7- 1

7.01 Main switch ..................................................................................................................7- 1

7.02 Foot switch ................................................................................................................... 7 - 1

7.03 Locking foot switch (optional) ........................................................................................ 7 - 2

7.04 Temperatureregulator/faultindicator............................................................................ 7 - 2

7.05 Status display of temperature control ............................................................................ 7 - 3

7.06 Regulator for drive roller start delay ............................................................................... 7 - 3

7.07 Regulator for heat-sealing speed.................................................................................... 7 - 4

7.08 Selection switch for operational modes ......................................................................... 7 - 4

7.09 Regulator for hot-air pressure (only on machines with hot-air) ....................................... 7 - 5

7.10 Regulatorfor feed rollerpressure ................................................................................... 7 - 5