Pfeiffer Vacuum TIC 253 User manual

Betriebsanleitung • Operating Instructions

PT0138BE/A (0507)

TIC 253

TIC 254

Profibus-DP gateway for

TCP 350 and TCP/TM 3000

2

Inhalt

Inhalt

Hinweis! Aktuelle Betriebsanleitungen sind auch über

das Internet unter www.pfeiffer-vacuum.net verfügbar.

1. Safety Precautions 3

1.1 Pictogram Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 For Your Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Product Description 4

2.1 Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Proper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Improper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Installation 6

3.1 Preparations For Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Profibus Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Operation 8

5. Modules 9

5.1 Module 1: "standard" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2 Module 2: "power" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.3 Module 3: "ophrs_pump" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.4 Module 4: "ophrs_drv" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.5 Module 5: "tms" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.6 Module 6: "venting" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.7 Module 7: "fixed_value_out" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.8 Module 8: "fixed_value_in". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.9 Module 13: "fail_safe" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.10 Module 14: "acyclic access". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6. Extended Diagnosis Data 15

7. What To Do In Case Of Breakdowns? 15

8. Maintenance And Service 16

9. Technical Data 16

10. Accessories 16

11. Valid Parameters 17

11.1 Caption for List of Valid Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3

Safety Precautions

1. Safety Precautions

☞Read and follow all the instructions in this manual.

☞Inform yourself regarding:

– Hazards which can be caused by the unit,

– Hazards which can arise in your system.

☞Comply with all safety and accident prevention regulations.

☞Check regularly that all safety requirements are being complied with.

☞Take account of the ambient conditions when installing the TIC 253/254.

– The protection type of the TIC 253/254 is IP20/IP 54 when assembling accurate.

☞Do not carry out any unauthorised conversions or modifications on the unit.

☞Do not open the housing cover when the unit is connected to the mains nor during

pumping operation.

☞Take account of the prescribed voltage when connecting the cable to the various

plugs.

☞When returning the unit to us please note the shipping instructions.

1.1 Pictogram Definitions

1.2 For Your Orientation

Operating Instructions In The Text

➡Here, you have to do something!

Caution

Caution, danger of damage to the pump or system.

Please note

☞

Attention to particularly important information on the pro-

duct, handling the product, or to a particular part of the

documentation.

4

Product Description

2. Product Description

The TIC 253 respectively TIC 254 provides a connection for the bus system Profibus-DP

(V0) for the drive units TCP 350 and TCP 3000 respectively TM 3000. If not stated other-

wise the designation "TIC" applies to the TIC 253 and also to the TIC 254.

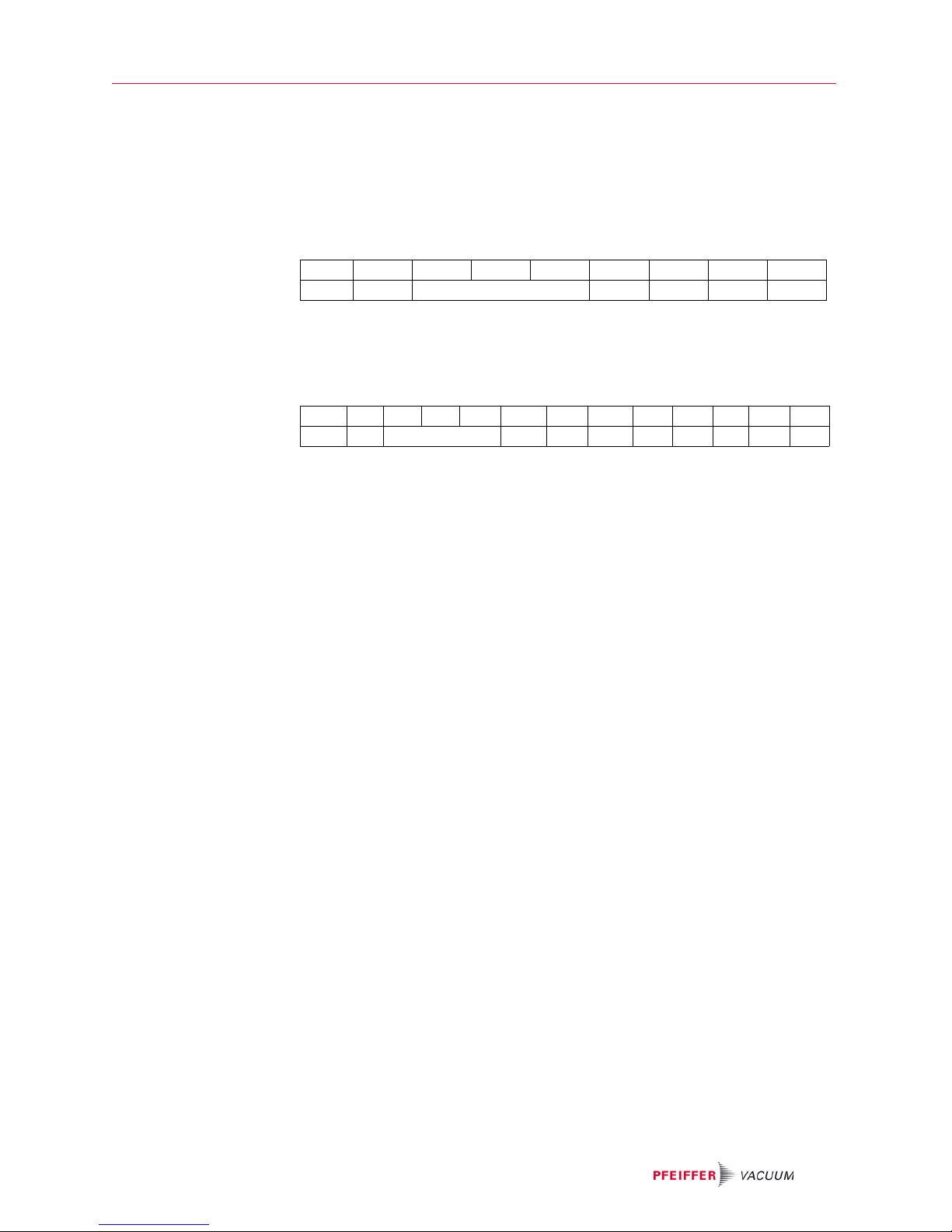

Abb. 2-1 Description of the front panel

Connection options The TIC offers connection options for the Profibus-DP by means of a 9-way Sub-D sok-

ket (TIC 253) respectively by means of two B-coded M12 connectors (TIC 254).

2.1 Delivery

Included with the delivery of the TIC 253/254 are the following items:

• Unit TIC 253 respective TIC 254

• CD with GSD file and graphics for inclusion in the Profibus configuration tool.

2.2 Proper Use

The TIC serves the purpose of connecting the aforementioned drive units to the Profi-

bus-DP (V0). The type of protection stated for the TIC 254 can only be attained in the

case of correctly fitted rubber stoppers to the address selector switches and the service

connection as well as with connected Profibus connectors, respectively connector with

terminating resistor.

1

1

2

5

3

4

3

4

1

2

TIC 253

TIC 254

➀Profibus-DP connection

➁Status display

➂Profibus-DP Address

(hexadecimal, most significant bit „msd“)

➃Profibus-DP Address

(hexadecimal, least significant bit „lsd“)

➄Service connection

5

Product Description

2.3 Improper Use

Improper is:

– Uses not covered above, and, in particular,

– Connection to pumps and units which is not permitted in their operating instruc-

tions.

– Connection to units which contain touchable and voltage carrying parts.

Improper use will cause any rights regarding liability and guarantees to be forfeited.

6

Installation

3. Installation

3.1 Preparations For Installation

➡Connect the Profibus cable to the TIC and secure it against inadvertent loosening by

screwing it down. When doing so, note the applicable regulations and recommenda-

tions for installing a Profibus system.

➡Set the address selector switch to the Profibus address intended for this instru-

ment.

➡TIC 254: fit the rubber stoppers to the address selector switches so as to attain the

type of protection stated. The stoppers must be inserted straight and as deeply as

possible into the holes.

➡To configure the TIC use the enclosed GSD file. Information on this can be found

with your Profibus configuration tool and in the see Chap. 5., page 9.

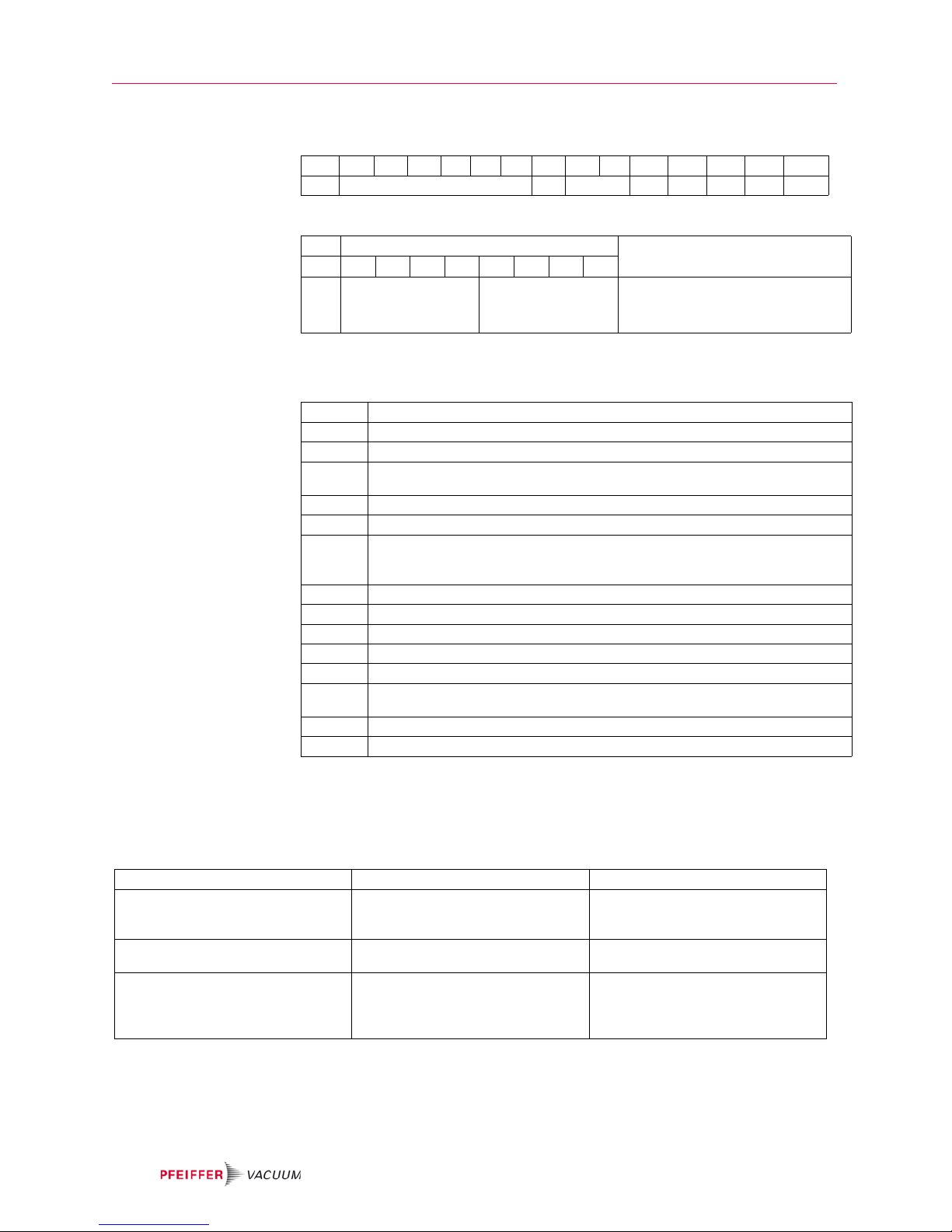

3.2 Profibus Connection

The Profibus is connected to this box. The pin arrangement is in accordance with the

Profibus standard. Thereby the functions are supported in accordance with the pin assi-

gnment in the table below. It is recommended to tighten the securing screws of the plug

to prevent unintentional disconnection of the plug.

TIC 253 Pin Function

1Shield

2-

3 RxD/TxD-P

4CNTR-P

5 DGND

6VP

7-

8 RxD/TxD-N

9-

TIC 254 Pin Function

plug

socket

1VP

2 RxD/TxD-N

3DGND

4 RxD/TxD-P

5 Shield

Socket and plug are wired in

parallel so that they provide the

same functions.

For the Profibus connection of the TIC 254 you may use

the kits listed as accessories, see Chap. 10., page 16

Tabelle 3.2.1: Pin assignment Profibus connector

9

8

7

6

5

4

3

2

1

5

2 1

3 4

5

1 2

4 3

7

Installation

Address Selector Switch The Profibus address is set up with the address selector switch using hexadecimal co-

ding. For conversion of decimal to hexadecimal addresses please refer to Table 3.2.2 on

page 7.

➡TIC 254: Fit the rubber stoppers to the address selector switches so as to attain the

type of protection stated. The stoppers must be inserted straight and as deeply as

possible into the holes.

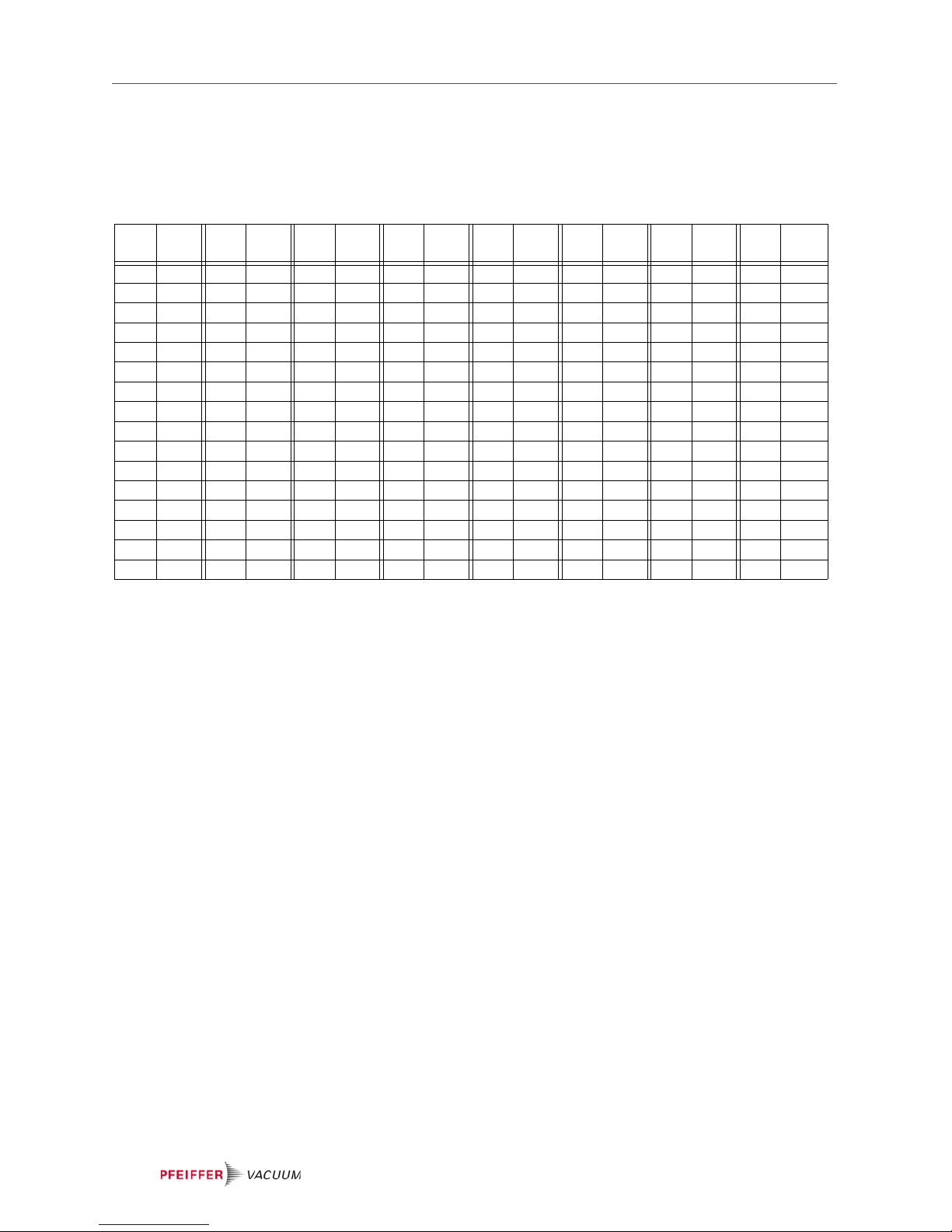

Tabelle 3.2.2: Profibus-DP address (hexadecimal): Conversion to decimal data

➂➃ Adr. ➂➃ Adr. ➂➃ Adr. ➂➃ Adr. ➂➃ Adr. ➂➃ Adr. ➂➃ Adr. ➂➃ Adr.

hex. dez. hex. dez. hex. dez. hex. dez. hex. dez. hex. dez. hex. dez. hex. dez.

00 0 10162032304840645080609670112

01 1 11172133314941655181619771113

02 2 12182234325042665282629872114

03 3 13192335335143675383639973115

04 4 142024363452446854846410074116

05 5 152125373553456955856510175117

06 6 162226383654467056866610276118

07 7 172327393755477157876710377119

08 8 182428403856487258886810478120

09 9 192529413957497359896910579121

0A 10 1A 26 2A 42 3A 58 4A 74 5A 90 6A 106 7A 122

0B 11 1B 27 2B 43 3B 59 4B 75 5B 91 6B 107 7B 123

0C 12 1C 28 2C 44 3C 60 4C 76 5C 92 6C 108 7C 124

0D 13 1D 29 2D 45 3D 61 4D 77 5D 93 6D 109 7D 125

0E 14 1E 30 2E 46 3E 62 4E 78 5E 94 6E 110 7E 125

0F 15 1F 31 2F 47 3F 63 4F 79 5F 95 6F 111 7F 125

8

Operation

4. Operation

Before operating the TIC for the first time the valid and unique serial interface address

has to be set by means of the Profibus address selection switch. Alterations to the

address during operations are not permissible.

Illuminating Displays

This LED provides information on the general unit status and the communication with

the TIC unit. Upon switching on there is a test phase of approximately one second for

the LED. Only thereafter will the Table 4.0.1 on page 8 be valid.

Please note

☞

In the case of the TCP 350 (TIC 253) the time which elapses between switching on the

instrument until the Profibus is available may amount to approximately

15 seconds!

Status Definition

Off Unit is not supplied with adequate voltage

Green illuminating Communication with the TIC unit running (status

data_exchange)

Green flashing Bus traffic detected, no data_exchange

Green 1 x short, 1 x long flashing The set address is not the one with which the unit is

currently working Abb. 2-1, Page 4

Red illuminating Unit defective

Red flashing No bus traffic detected

Red 1 x short, 1 x long flashing Current parameter data are erroneous

Red 2 x short, 1 x long flashing Current configuration data are erroneous

Tabelle 4.0.1: Illuminating Displays

9

Modules

5. Modules

Select the modules depending on which data you want to exchange with the drive unit.

➡Thereby configure module modul 1 always first and use only once. As to restrictions

of the parameter values and parameter numbers please refer to the Operating

Manuals of the drive units used.

➡Please also note the following:

Tabelle 5.0.1: Modules overview

Output data:

Contains data from the master (e.g. PLC) to the TIC.

Input data:

Contains data from the TIC to the master (e.g. PLC).

Configuration data:

Contains identification of the module.

Parametering data:

Contains additional module-specific information.

PLEASE NOTE

☞

– A maximum of 18 modules can be used.

– In the input data of the modules a maximum of 42 parameters may be present

[Pxxx].

– In the configuration no other module may be present after the "fail_safe" mo-

dules.

– In order to update the input data as rapidly as possible, please use only the mo-

dules you really require and do not use multiple parameter numbers.

– Access to the functions in the modules can be influenced by external circuitry

of the drive unit used (refer to the Operating Manual of the drive unit).

# Modules Description I- O-

Data (Byte)

1 standard Standard functions 4 3

2 power Current and Voltage 4 0

3 ophrs_pump Operating hours pump 4 0

4 ophrs_drv Operating hours drive 4 0

5 TMS TMS heating 1 1

6 venting Venting 0 3

7 fixed_value_out 1 parameter value output 0 2

8 fixed_value_in 1 parameter value input 2 0

13 fail_safe Behaviour if communication fails 0 0

14 acyclic access acyclic access 12 8

10

Modules

5.1 Module 1: "standard"

This module must always be configured first and must be used only once.

Output data:

a: Pre-selection heating [P001]: 0 – off, 1 – on

b: Stand by [P002]: 0 – off, 1 – on

c: Error acknowledgement [P009]: only when a malfunction is present to 1, otherwise

0

d: Pumping station [P010]: 0 – off, 1 – on

e: Motor [P023]: 0 – off, 1 – on

f: Operating mode pump [P026]: 0 – final rotation speed mode, 1 – rotation speed set-

ting mode (see pos. h:)

g: Run-up time monitoring [P004]: 0 – off, 1 – on

h: Set rotation speed as a % of the final rotation speed [rounded P707], only then

valid in rotation speed setting mode (f: is switched to 1)

i: Rotation speed switch point as a % of the final rotation speed [P701]

Input data:

a: Unit remote controlled [P300]: 0 – no, 1 – yes

b: Switchpoint attained [P302]: 0 – no, 1 – yes

c: Set rotation speed attained [P306]: 0 – no, 1 – yes

d: Pump accelerates [P307]: 0 – no, 1 – yes

e: TMS controller responded [P333]: 0 – no, 1 – yes

f: Actual rotation speed as a % of the final rotation speed

g: Error/Warning number (low byte): 0 – no error, 1...999 – error 1...999, 1001...1999 –

warning 1...999

h: Error/Warning number (high byte)

i: Oil deficiency

j: Excess temperature [P304, P305]: 0 – no, 1 – yes

Configuration data:

C1h, 02h, 83h, 01h

PLEASE NOTE

☞

The fields "h" and "i" must always be filled with valid values (for example 50), even though

these functions are not used.

Byte 012

Bit 76543210

abcdefg - h i

Byte 012 3

Bit 76543210 765 4... 0

abcde - - - f g i j - h

11

Modules

5.2 Module 2: "power"

This module may only be used a maximum of once.

Input data:

Configuration data:

41h, 41h, 02h

5.3 Module 3: "ophrs_pump"

This module may only be used a maximum of once.

Input data:

Configuration data:

41h, 83h, 03h

5.4 Module 4: "ophrs_drv"

This module may only be used a maximum of once.

Input data:

Configuration data:

41h, 83h, 04h

Byte 0123

Current in 10 mA [P310] Voltage in 10 mV [P313]

low byte high byte low byte high byte

Byte 012 3

Operating hours of the pump [P311]

low word /

low byte

low word /

high byte

high word /

low byte

high word /

high byte

Byte 012 3

Operating hours of the electronic drive unit [P314]

low word /

low byte

low word /

high byte

high word /

low byte

high word /

high byte

12

Modules

5.5 Module 5: "tms"

This module may only be used a maximum of once.

Output data:

Input data:

Configuration data:

C1h, 00h, 00h, 05h

5.6 Module 6: "venting"

This module may only be used a maximum of once.

Output data:

Configuration data:

81h, 82h, 06h

5.7 Module 7: "fixed_value_out"

With this module an additional parameter can be described the parameter number of

which is stated in the parameter data (low byte first). The output data must then contain

a valid setpoint. For possible parameters see Chap. 11., page 17.

Output data:

Configuration data:

81h, C0h, 07h

Parametering data:

Byte 0

Set value TMS heating in °C [P704]

Byte 0

Actual value TMS heating in °C [P331]

Byte 012

Venting frequency as a

% of the final rotation

speed [P720]

Venting time in s [P721]

low byte high byte

Byte 01

Parameter value

low byte high byte

Byte 01

Parameter number

low byte high byte

13

Modules

5.8 Module 8: "fixed_value_in"

With this module an additional parameter can be read the parameter number of which

is stated in the parameter data (low byte first). The input data then contain the current

value. As to the possible parameters see Chap. 11., page 17.

Input data:

Configuration data:

41h, C0h, 08h

Parametering data:

5.9 Module 13: "fail_safe"

Through this module you can state which actions the TIC shall perform in the Profibus

status „fail_safe“, for example switch pump off in case the Profibus connection fails. In

the parameter data, the parameter number and the parameter value are stated which

shall be written in this case. As to the possible parameters see Chap. 11., page 17. This

module can be used up to four times in the configuration.

Configuration data:

00h

Parametering data:

Byte 01

Parameter value

low byte high byte

Byte 01

Parameter number

low byte high byte

Please note

☞

Please note that your Master may possibly attain during starting of the Profibus the sta-

tus "fail_safe" and that because of this these modules are run.

Byte 0123

Parameter number Parameter value

low byte high byte low byte high byte

14

Modules

5.10 Module 14: "acyclic access"

This module may be used for acyclic accesses. In the output data the command, the

path and possibly necessary data is output. After running, the input data contain the con-

firmation of the command, the path and possible additional information. Data is only ex-

changed in case the output data change.

Output data:

a: Service – e.g. read or write (see Chap. 11., page 17)

b: Path (see Chap. 11., page 17)

d0...d3: Data (don’t care on read access), format see Chap. 11., page 17

Input data:

a: Contains field a of output data with Bit 6 set (e.g.: 1 --> 65) on correct execution, on

error value 71.

b: Path, repeats path in output data

d0...d7: Data (don’t care on write access), format see Chap. 11., page 17

Configuration data:

C1h, 87h, 8Bh, 0Eh

Byte 01234567

a b d0 d1 d2 d3

Byte 012 3 4 5 6 7 891011

a b d0 d1 d2 d3 d4 d5 d6 d7

15

Extended Diagnosis Data

6. Extended Diagnosis Data

a: Laid down via the Profibus standard

b: General status of the TIC and of the connected drive unit:

c: d1...dx: Number of the 1., ... x. Module

d: e1...ex: Status of the 1., ... x. Module

7. What To Do In Case Of Breakdowns?

Byte 0 1 2 3 4 5 6 7 8 9 10 ... n-2 n-1

a b c d1 e1 ... dx ex

Byte 78

Bit 76543210

Error number drive

unit, Bit 3-0

TIC status

(0: ok,≠0: internal

error)

error number drive unit,

Bit 11-4

Status Meaning

0No module assigned

1Module status OK

2At least one parameter which is assigned to this module is not supported by the

connected electronic drive unit.

3The Parameter number selected in this module does not exist

4The transmitted parameter value in this module is outside the valid range.

5

An access logic error has occurred in this module: it has been attempted to write

to a parameter which is only readable or a parameter value to read which is only

writeable.

6This module does not support the data type of the addressed parameter.

7The "standard module" is not located in the first connection slot

8An error has been acknowledged although no error has occurred.

9The maximum number of permissible "fail_safe modules" has been exceeded.

10 Unknown module

13 The maximum permissible number of the requested parameter numbers has been

exceeded.

14 Modules which may use once, are used multiple.

15 This module cannot be used for the connected drive unit.

Tabelle 6.0.1: Module regarded error numbers

Problem Possible Reasons Resolution

Parametrization error

Low and high byte of the parameter

number is interchanged in the modules

fixed_value_in or –out

The parameter numbers are stated with

the low byte first.

Read data not plausible Low and high byte, respectively word of

the data is interchanged

The data is transmitted with the low

bite/word first.

Instrument or entire branch is not visible

on the Profibus Terminating resistor switched on

The terminating resistor may only be

switched on at the beginning and the

end of the bus, but not in the case of an

instrument in between.

16

Maintenance And Service

8. Maintenance And Service

The unit requires no maintenance. A damp cloth can be used to wipe away any dirt

which has collected on the front panel. Ensure that the unit is first disconnected from

the mains power supply.

Do Make Use Of Our Service Facilities!

In the event that repairs are necessary a number of options are available to you to ensure

any system down time is kept to a minimum:

• Return the unit to the manufacturer for repairs;

• Replace with a new value unit.

Local Pfeiffer Vacuum representatives can provide full details.

9. Technical Data

10. Accessories

CAUTION

The unit is not prepared for customer repair.

Units returned to us for repair or maintenance are covered by our general conditions of

sale and supply. Please refer to the back cover of this manual for contact addresses and

telephone hotline numbers

Description Unit TIC 253 TIC 254

Profibus version DP-V0

Baud rates baud 9,6 k; 19,2 k; 45,45 k; 93,75 k; 187,5 k; 500 k;

1,5 M; 3 M; 6 M; 12 M

Permissible ambient temperature °C 5 – 40

Max. relative humidity (non condensing) % (at 5 – 40 °C) 5 – 85

Air pressure kPa 86 – 106

Protection type IP 20 IP 54

Designation Number

Profibus connectors (male and female) M12B PM 051 927 -T

Profibus connector (female) and termination resistor M12B PM 051 928 -T

17

Valid Parameters

11. Valid Parameters

#Name

TCP 350

TCP 3000

TM 3000

contained

usable

in module

Pos. in I-/O data in module 14

(decimal)

7813a b dataformat

1 Preselection heating ●●

1●●●➏6, 2, 16 byte

2Standby ●●● 1●●●➏4, 1, 28 byte

4 Startup time monitoring ●●● 1●●●➏5, 1, 20 byte

8 Keyboard interlock ●● ●●●➏9, 1, 16 byte r

9 Error acknowledgement ●●● 1●63,1,0 -

10 Pumping station ●●● 1●●●➏5, 1, 16 byte

12 Venting release ●●● ●●●➏6, 4, 16 byte

13 Preselection brake ●●●●➏6, 3, 16 byte

19 Configuration switch output K2 ●●● ●●●➏9, 5, 17 byte

23 Motor TMP ●●● 1●●●➏4, 1, 30 byte

24 Configuration switch output K1 ●●●●➏9, 4, 17 byte

25 Operating mode BKP ●● ●●●➏6, 1, 17 byte

26 Operating mode TMP ●●● 1●●●➏4, 1, 23 byte

27 Gas mode ●●● ●●●➏4, 1, 21 byte

28 Operating mode remote ●●● ●●●➏9, 2, 17 byte

29 Operating mode drive unit ●●●●➏4, 1, 19 byte

30 Venting mode ●●● ●●●➏6, 4, 17 byte

50 Direct control seal gas valve ●●●●➏6, 6, 16 byte

52 Gas ballast valve ●➏6, 9, 17 byte

55 Configuration analog output 1 ●●● ●●●➏9, 10, 17 byte

95 Factory setting ●● ● 22 1, 1, 0 0

300 Unit remote controlled ●●● 1●19,2,18 byte

301 Oil deficiency TMP ●● 113,1,17 wordt

302 Rotation speed switch point attained ●●● 1●15,1,18 byte

303 Actual error code ●●● 1●13,1,18 wordu

304 Over temperature drive unit ●●● 113,1,17 wordt

305 Over temperature TMP/BKP ●●● 113,1,17 wordt

306 Set rotation speed attained ●●● 1●1 4, 1, 25 byte v

307 Pump accelerates ●●● 1●1 4, 1, 25 byte v

308 Set rotation speed (Hz) ●●● ● 1 4, 1, 27 dword

309 Actual rotation speed (Hz) ●●● 1➋ ●1 4, 1, 22 dword

310 Motor current (10 mA) ●●● 2●14,1,17 real

w

311 Operating hours pump (h) ●●● 3➌1 4, 1, 31 dword

312 Software version drive unit ●●● 1 1, 1, 23 byte u

313 Motor voltage (10 mV) ●●● 2●14,1,16 realw

314 Operating hours drive unit (h) ●●● 4➌1 1, 1, 30 dword

315 Final rotation speed (Hz) ●●● ● 1 4, 1, 26 dword

316 Motor power (W) ●●● ● 14,1,18 real

319 Cycle counter ●●● ➌1 5, 1, 19 dword

323 Temperature cooling plate ●●1 1, 1, 31 word u

329 Fanglagerverschleiß ●●1 4, 1, 34 word

331 Heating TMS, actual value ●5●16,2,19 word

333 TMS controller steady state ●1●16,2,18 byte

334 Max TMS temperature occurred ●●1 6, 2, 22 word

335 Heating type ●● ● 1 6, 2, 23 byte

346 Motor temperature ●● ● 1 4, 1, 32 word u

18

Valid Parameters

11.1 Caption for List of Valid Parameters

349 Unit type drive unit ●●● 11,1,17 byte

u

352 Software version motor controller ●●● 1 1, 2, 23 byte u

354 Hardware version ●●● 1 1, 1, 22 byte u

357 CPLD Version ●1 1, 2, 22 byte u

358 Out-of-balance amplitude A ●●

1 4, 1, 33 byte u

359 Out-of-balance amplitude B ●●

360 Malfunction memory, position 1 ●●● ● 13,2,18 word

u

361 Malfunction memory, position 2 ●●● ● 13,3,18 word

u

362 Malfunction memory, position 3 ●●● ● 13,4,18 word

u

363 Malfunction memory, position 4 ●●● ● 13,5,18 word

u

364 Malfunction memory, position 5 ●●● ● 13,6,18 word

u

365 Malfunction memory, position 6 ●●● ● 13,7,18 word

u

366 Malfunction memory, position 7 ●●● ● 13,8,18 word

u

367 Malfunction memory, position 8 ●●● ● 13,9,18 word

u

368 Malfunction memory, position 9 ●●● ● 13,10,18word

u

369 Malfunction memory, position 10 ●●● ● 13,11,18 word

u

700 Max. run-up time ●●● ● ● ● ➏ 5, 1, 21 byte

701 Switchpoint in % of final rotation speed ●●● 1●●●➏5, 1, 17 byte

704 TMS heating set value in °C ●5●●●➏6, 2, 20 word

707 Rotation speed set value in rot. speed set-

ting mode ●●● 1n❹❹❹➏4, 1, 24 real

710 Poff for VVP interval operation in W ●● ●●●➏6, 1, 21 word

711 Pon for VVP interval operation in W ●● ●●●➏6, 1, 22 word

717 Standby frequency ●●● ❹❹❹➏4, 1, 29 real

720 Venting frequency ●●● 6●●●➏6, 4, 22 dword

721 Venting time ●●● 6●●●➏6, 4, 20 word

777 Set value max. pump rotation speed ●●● ● ● 24 4, 1, 26 word

794 Parameter set ●● ➏ 9, 11, 16 byte

795 Service line ●● ➏ 9, 11, 17 word

797 Unit address ●●● ● ● ● ➏ 9, 12, 19 byte

➊in %

➋in % (with respect to [P315])

➌only valid to 65535

➍in 0.01 %

➎0: blocked, 1: released

➏Command 1: read 2: write

Comment

Data field in the output data is

not used. The column "Data"

describes the format in the

data field of the input data.

The column "Data" describes the

format of the information to be sta-

ted in the output data.

Example

Read standby:

A-data: 1, 4, 1, 28

--> E-data 65, 4, 1, 28, 0

(standby is off)

Switch standby on:

A-data: 2, 4, 1, 28, 1

--> E-data 66, 4, 1, 28 (ok)

Tabelle 11.1.1: Caption for List of Valid Parameters

19

Valid Parameters

The data appear left aligned in the corresponding data fields, excess digits are of no si-

gnificance. The following formats are possible:

– byte: 1 byte

– word: 1 word (d0 = low byte, d1 = high byte)

– dword: 1 double word (4 Byte, low byte/word first)

– real: Floating point number in accordance with IEEE 754 (4 bytes, low byte

first)

➐Bit 5 1: Insufficient oil,

0: Sufficient oil

Bit 3 1: Overtemperature,

0: No overtemperature

➑Field of the data type stated: first byte contains the number of subsequent elements, for

example:

p349 (field of byte): 7, 84, 67, 80, 32, 51, 53, 48 --> 7 elements: "TCP 350"

p360 (field of word): 1, 6, 0 --> 1 element (word = 2 Byte): value 6

➒0: stop

1: accelerating

2: at nominal speed

3: decelerating

➓in A respectively V

Tabelle 11.1.1: Caption for List of Valid Parameters

Pfeiffer Vacuum Technology AG · Headquarters/Germany

Tel. +49-(0) 64 41-8 02-0 · Fax +49-(0) 64 41-8 02-2 02 · info@pfeiffer-vacuum.de · www.pfeiffer-vacuum.net

Your Vacuum Technology Experts in

Turbo Pumps

Rotary Vane Vacuum Pumps

Roots Pumps

Dry Vacuum Pumps

Leak Test Units

Valves

Flanges, Feedthroughs

Vacuum Measurement

Gas Analysis

System Technology

Service

This manual suits for next models

1

Table of contents