XSMALL 01 INTRODUCTION

1.1 Documentation required

The following documentation is needed for repair procedures:

• Instructionbookletforspecicmodel

• Technicaldocumentationforspecicmodel(diagrams,explodedview,symptoncureand

servicemanual)

1.2 Tools and resources

Aswellasthestandardequipment,thefollowingisrequired:

Qty. Description Notes

1Screwdriver TorxT10

1 Pliers for Oetiker clamps

1 CC -A - Vdc tester

1 Digital thermometer Scalelimit>150°C

1SSC(SaecoServiceCenter) Programmer

1.3 Material

Description Notes

Thermal paste Heatingelement>200°C

Descaler Saeco Entkalker

Greasesolvent Personal preference

Silicone grease Safe to use with food

01/04

1.4 Safety warnings

Werecommendyouconsultthetechnicalmanualofthemachinebeforeperforminganymainte-

nance work.

Observeallapplicablestandardsrelatingtotherepairofelectricalappliances.

Alwaysdisconnectthepowerplugfromthemainsbeforebeginningrepairwork.

Alwaysdisconnectthepowerplugfromthemainsbeforebeginningrepairwork.

Disassemblingthemachine,theoperatormustpayattentiontohotandunder

Pressureparts:boiler,pin-boiler,valves,dispensing,steamtube,brewunit,

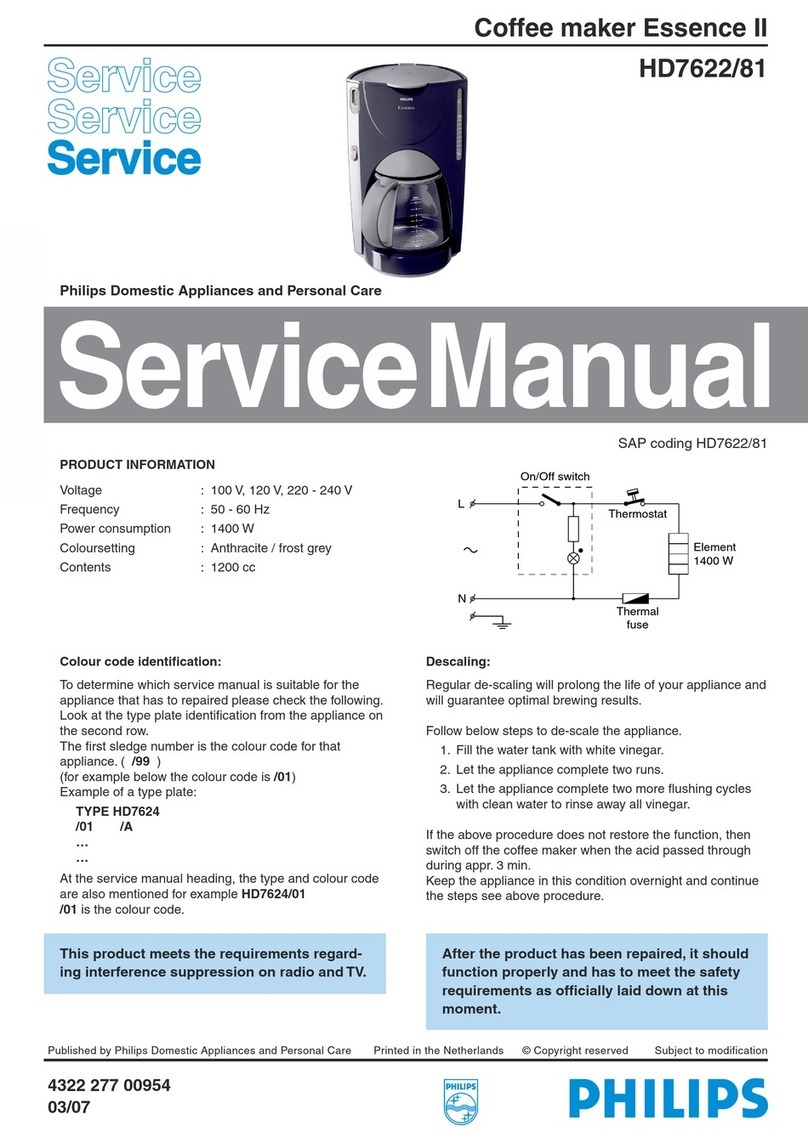

connectionsandpipestoavoidburns.Pleaserefertospecichydrauliccircuit

(Image1)toknowthepartsindetail.

Themachinehydrauliccircuitcanreachmaximumpressureof16/18bar.

TooperateinsafetyconditionisrecommendedtoperformtheSteamOutprocedurein

ordertoremovethepressureandhotwaterinsidethehydrauliccircuit.

WhenthemachinearrivesattheServiceCenterindescalingmodeinterrupted,ormakingDescal-

ing,beverycarefulnottocomeintocontactwiththeDescaler.

Aftertheproducthasbeenrepaired,itshouldfunctionproperlyandhastomeetthesafetyre-

quirementsandlegalregulationsasofciallylaiddownatthismoment

Simplyturningoffthemainmachinepowerswitchisnotanadequatesafety

precaution.

This domestic appliance is rated as insulation class I.

Oncompletionoftherepairwork,insulationanddielectricrigiditytestsmustbe

performed.