4. Operating logic

4.1. Water circuit 1

4.2. Control ringnut and valve 3

4.3. Coee cycle operating diagram 4

4.4. Single microswitch 5

4.5. Temperature sensor 5

4.6. Coee grinder function 6

4.7. Low bean level detection, dose quantity adjustment,

coee grinder blocked

6

4.8. Dose self-learning (SAS) 7

4.9. Water lter 7

5. Troubleshooting

5.1. Test Mode PHI 2000 Puro 1

5.2. Test Mode PHI 2000 Vapore 7

5.3. Steam out PHI 2000 Puro 13

5.4. Steam out PHI 2000 Vapore 14

6. Service and maintenance

6.1. Repair Flow 1

Table of contents Page

History (Modications to service manual)

1. Introduction

1.1. Documentation required 1

1.2. Tools and resources 1

1.3. Material 1

1.4. Safety warnings 1

1.5. Service Policy 3

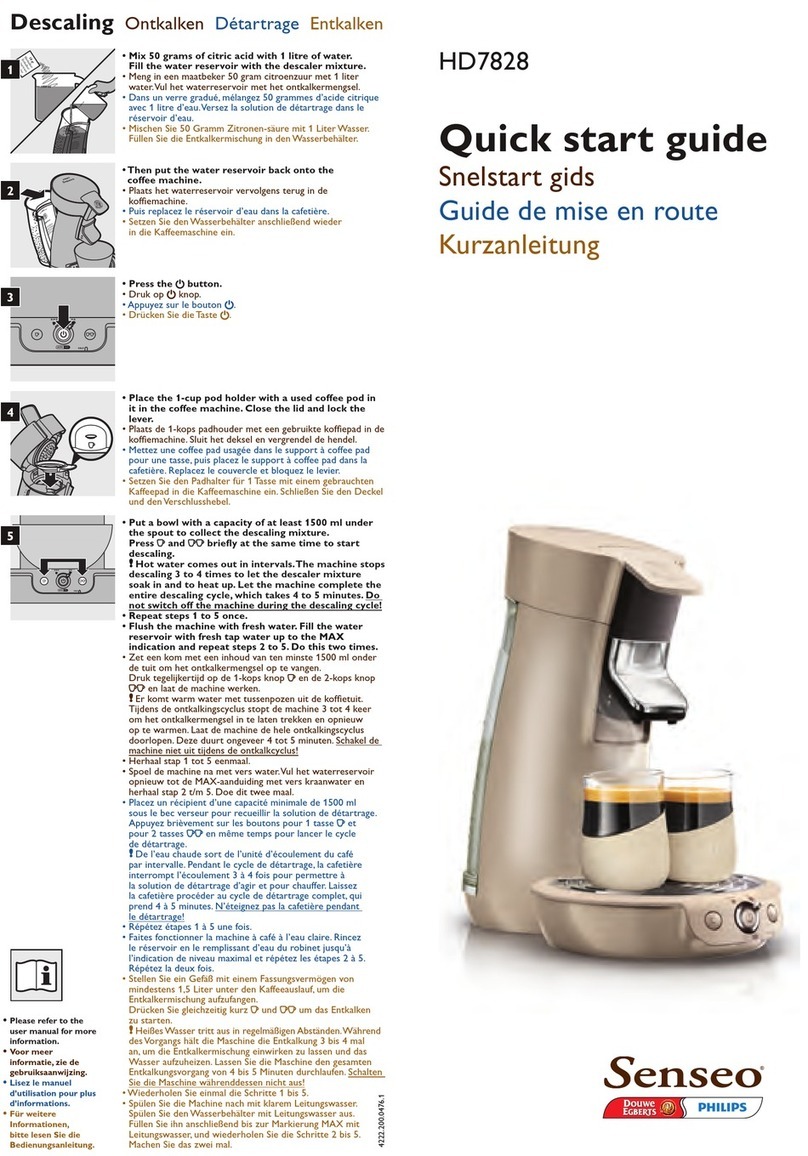

1.6.1. External machine parts (Puro) 4

1.6.2. External machine parts (Vapore) 5

1.6.3. Internal machine parts 6

2. Technical specications

2.1. Technical specications 1

2.2. Machine parameters and performance 1

2.3. Specication for the measurement of the coee products

temperature

2

2.3.1. Specication for the measurement of the Milk products

temperature.

3

2.4. Machine parameters and performance 5

3. User instructions

3.1. Customer menu PHI 2000 Puro 1

3.2. Customer menu PHI 2000 Vapore 5

3.3. Operation, cleaning and maintenance 9

Table of contents Page

History (Modications to service manual)

7. Disassembly

7.1. Outer Shell 1

7.2. KYB interface 2

7.3. e control knob and coee keys 2

7.4. e boiler pin 3

7.5. Gearmotor 4

7.6. e boiler 5

7.7. e ow selector fauced 5

7.8. e pump and turbine 6

7.9 e coee grinder 6

7.10. Grinder adjustment/assembly and disassembly 7

7.11. OETIKER clamps assembly and disassembly 8

8. Notes

9. Water circuit diagram

9.1. Water circuit diagram Puro 1

9.2. Water circuit diagram Vapore 2

10. Electrical diagram

10.1. Electrical diagram PHI 2000 Puro/Vapore 1

MODIFICATIONS TO SERVICE MANUAL

From Rev. To R e v. Chapter Inserted Modied

Rev.00 Rev01

01 Par. 1.4. Safety warnings

02 Par. 2.4 Descaling cycle frequency Par. 2.2.2 Specication for the measure-

ment of the Milk products temperature.

04 Par. 4.9. Water lter

06 Par. 6.1 Repair Flow