2

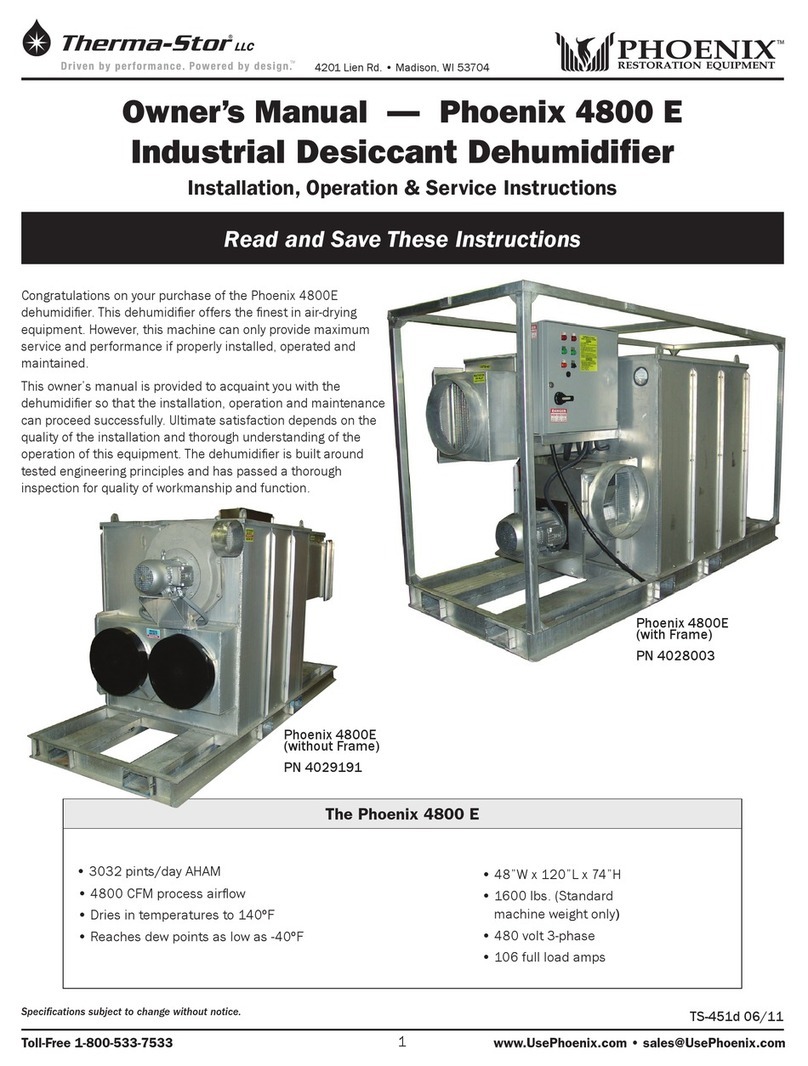

1 Specifications

Part No. 4028000

Power 230voltsinglephaseunit

withuserselectable25or40ampdraw

Water 344pints/day(43Gallons)

Removal @AHAM(80°F,60%)

Blower 900CFMProcessAirow

300CFMReactAirow

Operating -10ºFto140ºF

Range

Duct Process/ReactInlet:12”exduct(optional)

Options ProcessOutlet:8”exductorlayatx2

ReactivationOutlet:8”exduct(required)

Warranty 1yearPartsandService

Dimensions

Machine

Width 26.5”

Height 35”

Depth 45”

Weight 265lbs

Popular Accessories And Replacement Parts

4020550 24”x12”x2”PleatedMediaMERV-7

4024750 12”x25’FlexDuct

4024935 10”x250’Lay-atDuct

4024440 Kestrel3000Multi-Meter

2 Operation

Thefunctionofthedehumidieristoremovemoisture(in

thevaporstate)fromanairstream.Thisisaccomplished

byexposingtheairtoanadsorbingmedia(desiccant)in

asealedairstream(process).Afterthedesiccanthas

adsorbedmoisture,itisexposedtoasecondairstream

atanelevatedtemperature(reactivation).Thiscauses

themoisturetobedrivenoutofthedesiccantpreparingit

formoremoistureadsorption.Thisprocessisdoneona

continuousbasis,providingaconstantdryingprocess.

Thetwoairstreams(processandreactivation)areseparated

byseals,whichcontactthedesiccantmedia.Figure“A”

illustratestherelationshipofthesealsandairowpattern.

Thedehumidierisdesignedwiththetwoairstreamsowing

inoppositedirections(counterow)therebymaximizingthe

energyefciencyoftheequipment.

Table of Contents

Introduction......................................................................... 1

1. Specifications................................................................ 2

2. Operation......................................................................2

3. Installation Instructions..................................................3

3.1Inspection...............................................................3

3.2PlacingTheMachine................................................ 3

3.3Electrical.................................................................3

3.4DuctWork...............................................................3

4. Operating Instructions.................................................... 3

4.1Airow....................................................................3

4.2DesiccantWheelRotation........................................3

5. Start-Up........................................................................ 3

5.1ManualOperation....................................................3

5.2AutomaticOperation................................................ 3

5.3Make-UpAirVent.....................................................4

6. Controls........................................................................4

6.1ControlSwitch......................................................... 4

6.2High/LowSwitch.....................................................4

6.3UnitRunLight......................................................... 4

6.4Humidistat.............................................................. 4

6.5ElectricReactivationControls................................... 4

7. Dehumidifier Maintenance Instructions............................4

7.1GeneralMaintenance...............................................4

7.2Cabinet................................................................... 4

7.3Filter....................................................................... 4

7.4FanandMotor.........................................................4

8. Drive Motor................................................................... 5

8.1RotorDriveBelt.......................................................5

8.2Seals......................................................................5

8.3DesiccantMedia......................................................5

9. Dehumidifier Service Instructions....................................5

9.1RemovingDesiccantRotor........................................5

9.2ChangingSeals....................................................... 5

9.3InstallingSeals........................................................5

9.4Troubleshooting....................................................... 6

10. Service Parts.................................................................7

11. Wiring Diagram............................................................. 8

Warranty.......................................................................9

SerialNo._________________________________________

PurchaseDate_________/_________/_________

Dealer’sName_____________________________________

Read the operation and maintenance instructions carefully before

using this unit. Proper adherence to these instructions is essential

to obtain maximum benefit from your Phoenix 1200 dehumidifier.

•ItisdesignedtobeusedINDOORS ONLY.

•Ifusedinawetarea,plugitintoaGROUND FAULT

INTERRUPTER.

•DO NOTusethePhoenix1200asabenchortable.

•Itmustalwaysbeusedintheuprightposition.