USEPHOENIX.COM | 800-533-7533

2

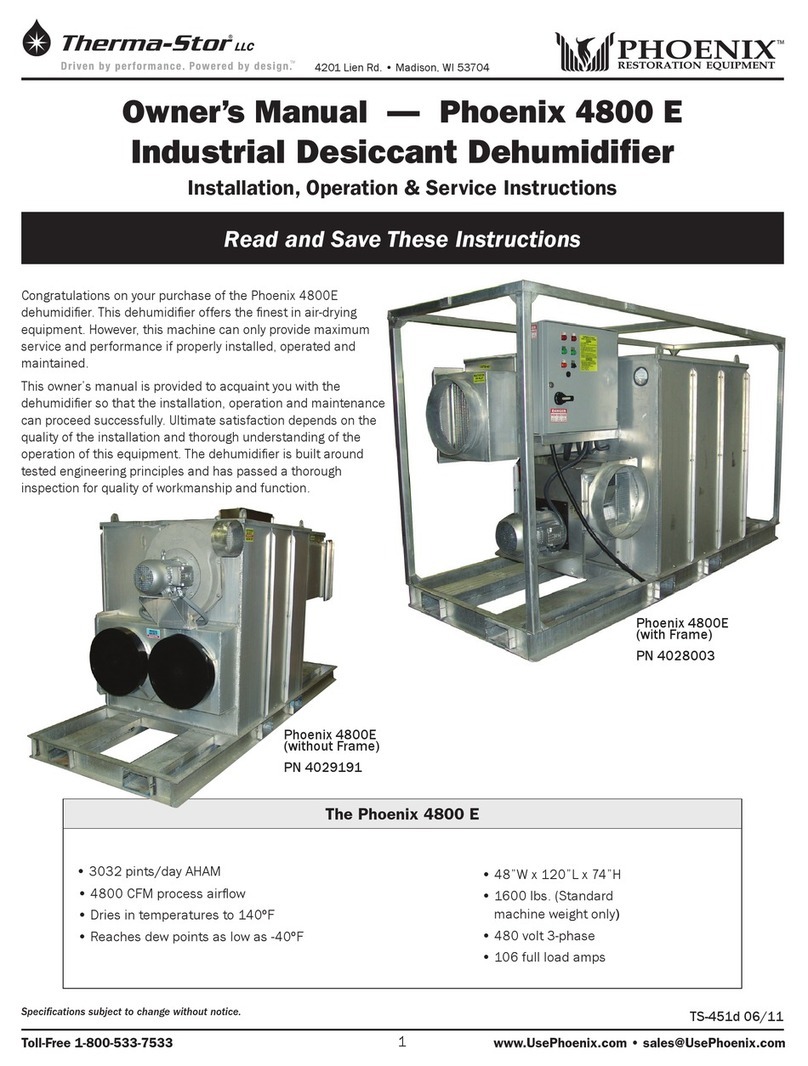

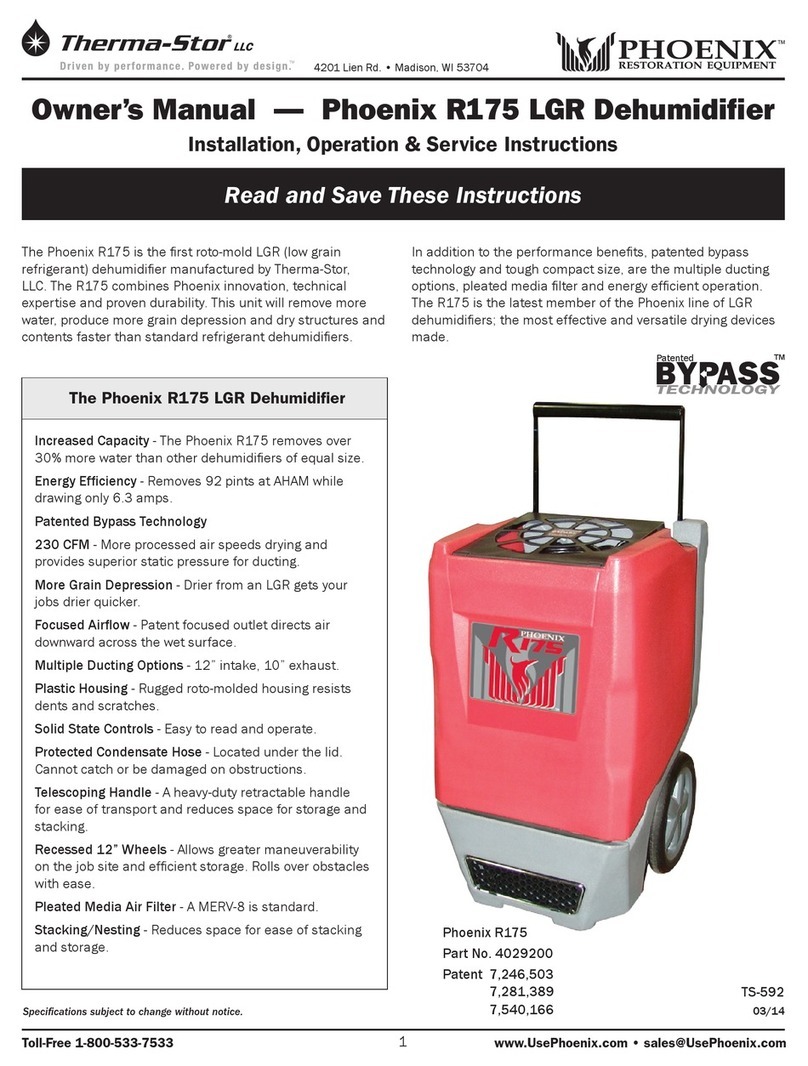

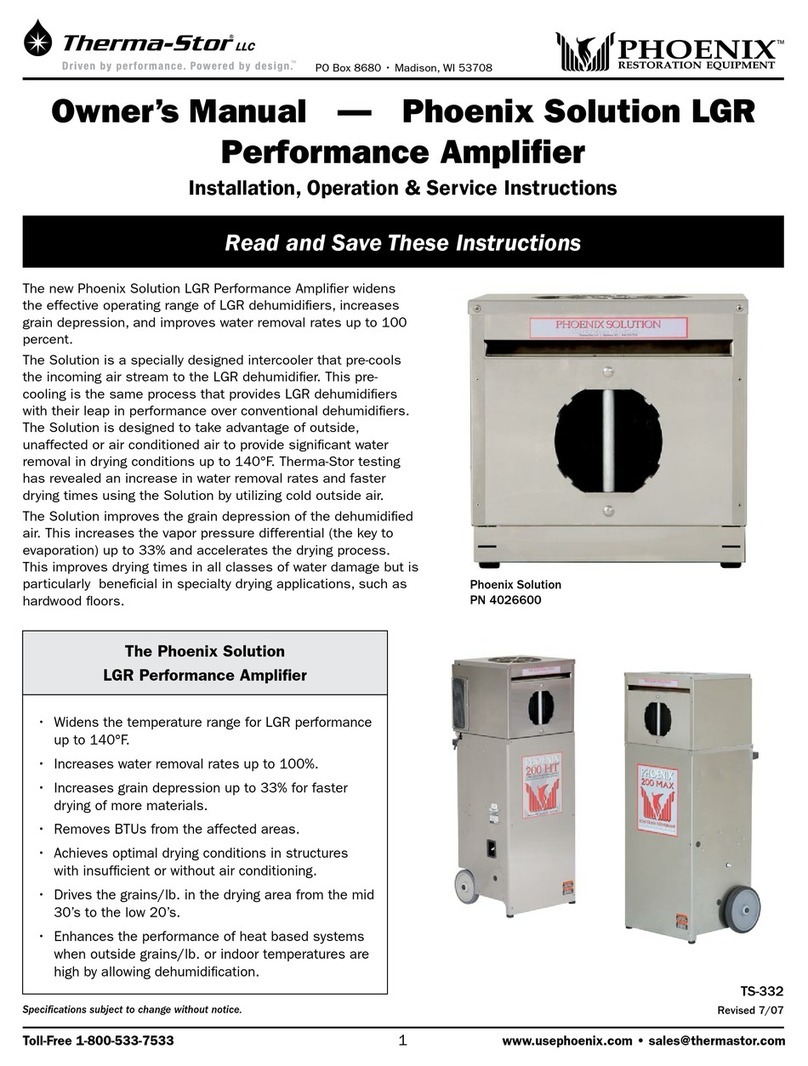

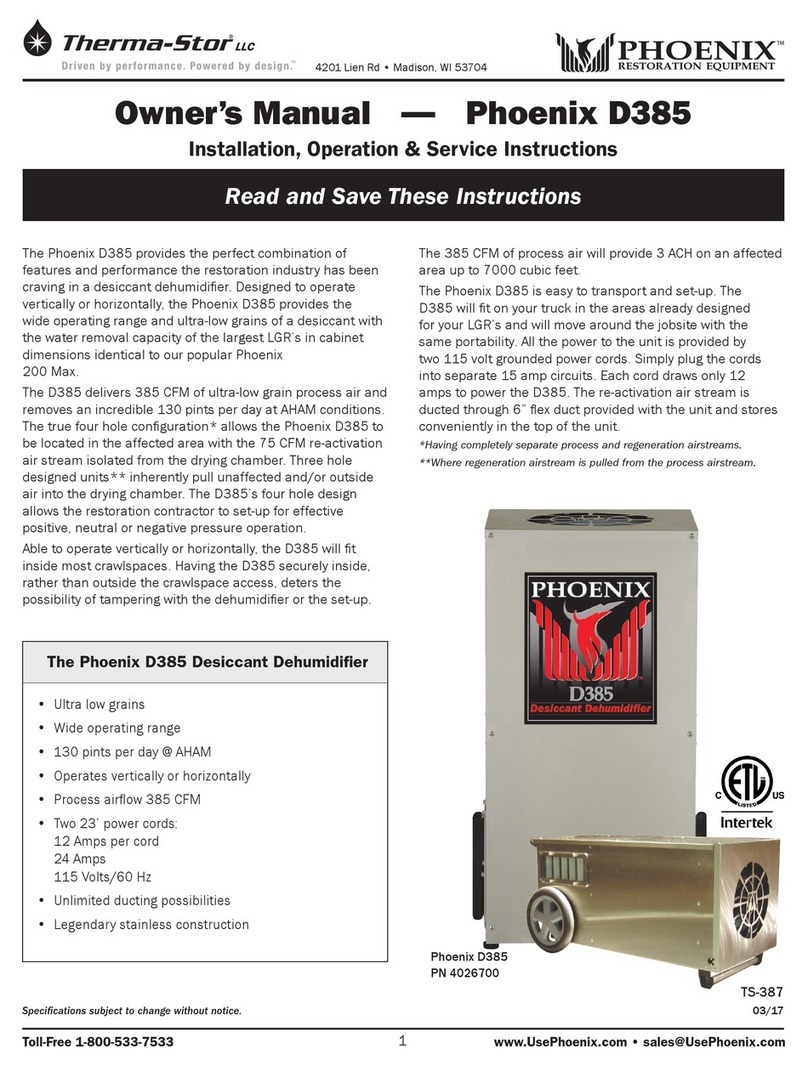

R250| LGR Dehumidifier Installation, Operation, and Maintenance Instructions

Table of Contents

1 Specifications

2 Important Safety Instructions

3 Operation

3.1 Transporting the Phoenix R250...................................

3.2 Location.......................................................................

3.3 Electrical Requirements..............................................

3.4 Condensate Removal...................................................

3.5 Ducting.........................................................................

3.6 Defrost Cycle................................................................

3.7 Power Switch................................................................

3.8 Pump Purge Switch......................................................

3.9 Hour Meter...................................................................

3.10 Bypass Control..........................................................

4 Maintenance

4.1 Air Filter........................................................................

4.2 Storage and Freeze Protection....................................

4.3 Service.........................................................................

5 Service

5.1 Technical Description...................................................

5.2 Troubleshooting............................................................

5.3 Air Mover.......................................................................

5.4 Condensate Pump........................................................

5.5 Float Safety Switch......................................................

6 Option & Accessories

7 Wiring Diagram

8 Service Parts

9 Warranty

Serial No.__________________________________

Purchase Date_____________________________

Dealer’s Name_____________________________

Read the operation and maintenance instructions carefully before using this unit. Proper adherence

to these instructions is essential to obtain maximum benefit from your Phoenix R250 dehumidifier.

WARNING

• It is designed to be used INDOORS ONLY.

• If used in a wet area, plug it into a GROUND FAULT INTERRUPTER.

• DO NOT use the Phoenix R250 as a bench or table.

• It must always be used in the upright position.