Ultra-Aire SD12 Installer’s & Owner’s Manual

8

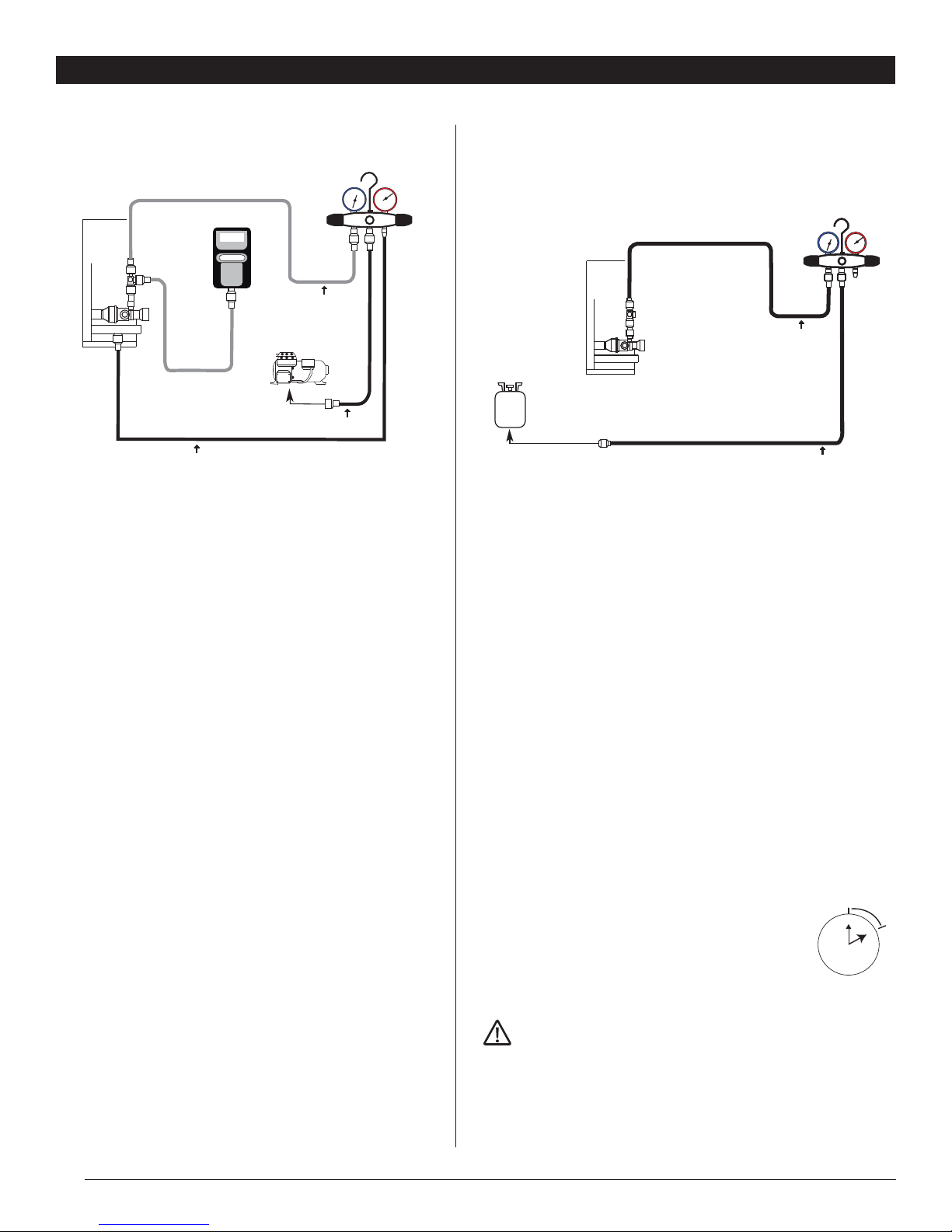

The maximum allowable elevation difference between the de-

humidifier and condensing unit is 30 feet (See FIGURE 8A). If the

elevation difference between the dehumidifier and condensing

unit is greater than 16 feet, an oil trap (as shown above) should be

created in the line set (See FIGURE 8B).

3.4 Brazing the Line Set

WARNING! POLYOL ESTER (POE) OILS USED

WITH HFC-410A REFRIGERANT ABSORB MOISTURE VERY

QUICKLY. IT IS VERY IMPORTANT THAT THE REFRIGERANT

SYSTEM BE KEPT CLOSED AS MUCH AS POSSIBLE. DO NOT

REMOVE LINE SET CAPS OR SERVICE VALVE STUB CAPS UNTIL

YOU ARE READY TO MAKE CONNECTIONS.

WARNING! WHEN USING A HIGH PRESSURE GAS

SUCH AS DRY NITROGEN TO PRESSURIZE A REFRIGERATION

OR AIR CONDITIONING SYSTEM, USE A REGULATOR THAT CAN

CONTROL THE PRESSURE DOWN TO 1 OR 2 PSIG.

CAUTION! BRAZING ALLOYS AND FLUX CON-

TAIN MATERIALS WHICH ARE HAZARDOUS TO YOUR HEALTH.

AVOID BREATHING VAPORS OR FUMES FROM BRAZING

OPERATIONS. PERFORM OPERATIONS ONLY IN WELL-VENTI-

LATED AREAS. WEAR GLOVES AND PROTECTIVE GOGGLES OR

FACE SHIELD TO PROTECT AGAINST BURNS. WASH HANDS

WITH SOAP AND WATER AFTER HANDLING BRAZING ALLOYS

AND FLUX.

IMPORTANT! TO PREVENT STRIPPING OF THE

VARIOUS CAPS USED, THE APPROPRIATELY SIZED WRENCH

SHOULD BE USED AND FITTED SNUGLY OVER THE CAP BEFORE

TIGHTENING.

IMPORTANT! ALLOW BRAZE JOINT TO COOL

BEFORE REMOVING THE WET RAG FROM THE SERVICE VALVE.

TEMPERATURES ABOVE 2500 CAN DAMAGE VALVE SEALS.

IMPORTANT! USE SILVER ALLOY BRAZING

RODS WITH 5% MINIMUM SILVER ALLOY FOR COPPER-TO-

COPPER BRAZING. USE 45% MINIMUM SILVER ALLOY FOR

COPPER-TO-BRASS AND COPPER-TO-STEEL BRAZING.

FOR HVAC INSTALLER ONLY

WARNING! FIRE, EXPLOSION AND PERSONAL SAFETY

HAZARD. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN

DAMAGE, PERSONAL INJURY OR DEATH. NEVER USE OXYGEN TO

PRESSURIZE OR PURGE REFRIGERATION LINES. OXYGEN WHEN

EXPOSED TO A SPARK OR OPEN FLAME, CAN CAUSE FIRE AND/OR AN

EXPLOSION, THAT COULD RESULT IN PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

Note – There is a service port inside the dehumidifier (on the gas line)

and both stub tubes of condensing unit. These service ports can be used

to introduce and release nitrogen during brazing.

Use the following procedure to connect the line set to the

Dehumidifier:

CAUTION! THE DEHUMIDIFIER IS SHIPPED FROM THE

FACTORY PRESSURIZED WITH A CHARGE OF INERT GAS AND WITH

RUBBER PLUGS IN THE LINES. PURGE THE INERT GAS FROM THE

DEHUMIDIFIER BY REMOVING THE RUBBER PLUGS IN THE LIQUID

AND GAS LINES TO RELEASE THE INERT GAS BEFORE CONNECTING

THE LINE SET.

Note – If there is no pressure in the dehumidifier when the first plug is

removed, check the dehumidifier for damage and leaks before continu-

ing with the installation.

1. Purge the inert gas from the dehumidifier by removing the rubber

plugs in the liquid and gas lines to release the inert gas before con-

necting the line set.

2. Place a field-provided heat shield, such as a wet rag, against the

dehumidifier and around the piping stubs. The heat shield must be in

place to protect the cabinet from heat damage.

3. Swage the liquid and gas lines (if necessary) to fit onto the dehumidi-

fier lines.

4. Purge the dehumidifier lines and the line set with dry nitrogen (Inert

gas) to prevent oxidation during brazing. Flow dry nitrogen into the

lines at a low pressure of 1 to 2 psig.

5. Braze the line set lines to the dehumidifier lines.

6. Remove the heat shield after brazing and allow the connections to cool.

Use the following procedure to connect the line set to the

Condensing Unit:

1. Cut the line set lines to the proper required length. Deburr the cut

ends of the line set lines.

2. Fit the line stubs with flare fittings (included with the condensing unit)

onto the line set if necessary.

3. Swage the liquid and gas lines (if necessary) to fit onto the line stubs

with the flare fittings.

4. Remove service valve caps and cores.

5. Purge the lines with dry nitrogen (Inert gas) to prevent oxidation dur-

ing brazing.

6. Braze the line set lines to the line stubs.

7. Apply a light coating of refrigeration oil to the flare fitting threads on

the condensing unit valves.

8. Start each flare nut on the corresponding flare fitting on the con-

densing unit valves by hand, making sure the threads are properly

engaged. Tighten the flare nuts hand tight.

30 FT

MAX

CONDENSING

UNIT

OIL TRAP

DEHUMIDIFIER

FIGURE 8B