PHANTA User Manual V1.4

TABLE OF CONTENTS

1. Introduction ............................................................................................................................. 3

2. Available models..................................................................................................................... 3

3. Packing List............................................................................................................................. 3

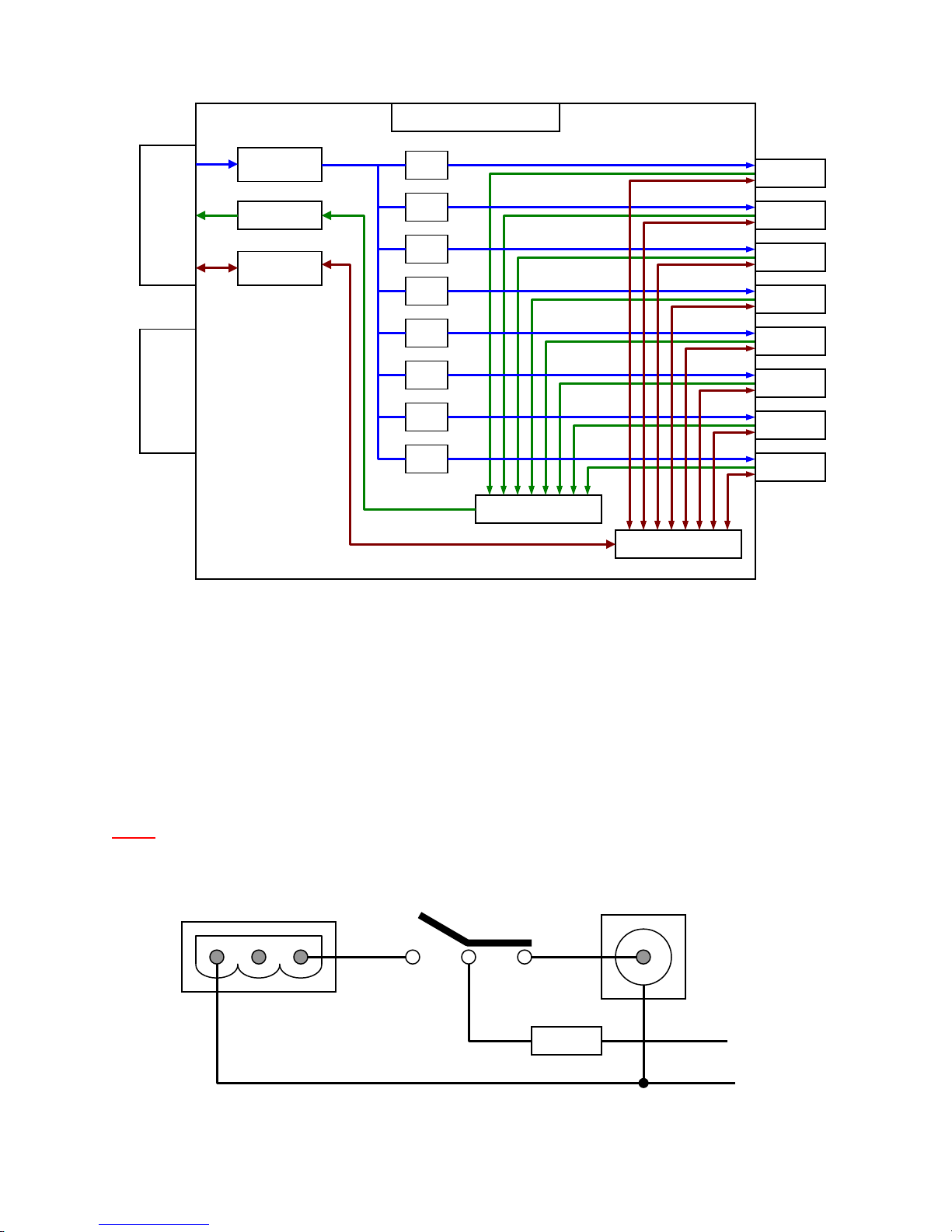

4. Model Functionality ................................................................................................................ 4

4.1 PHANTA-S1F4 ............................................................................................................ 4

4.2 PHANTA-D2B4............................................................. Error! Bookmark not defined.

4.3 PHANTA-S1B8............................................................. Error! Bookmark not defined.

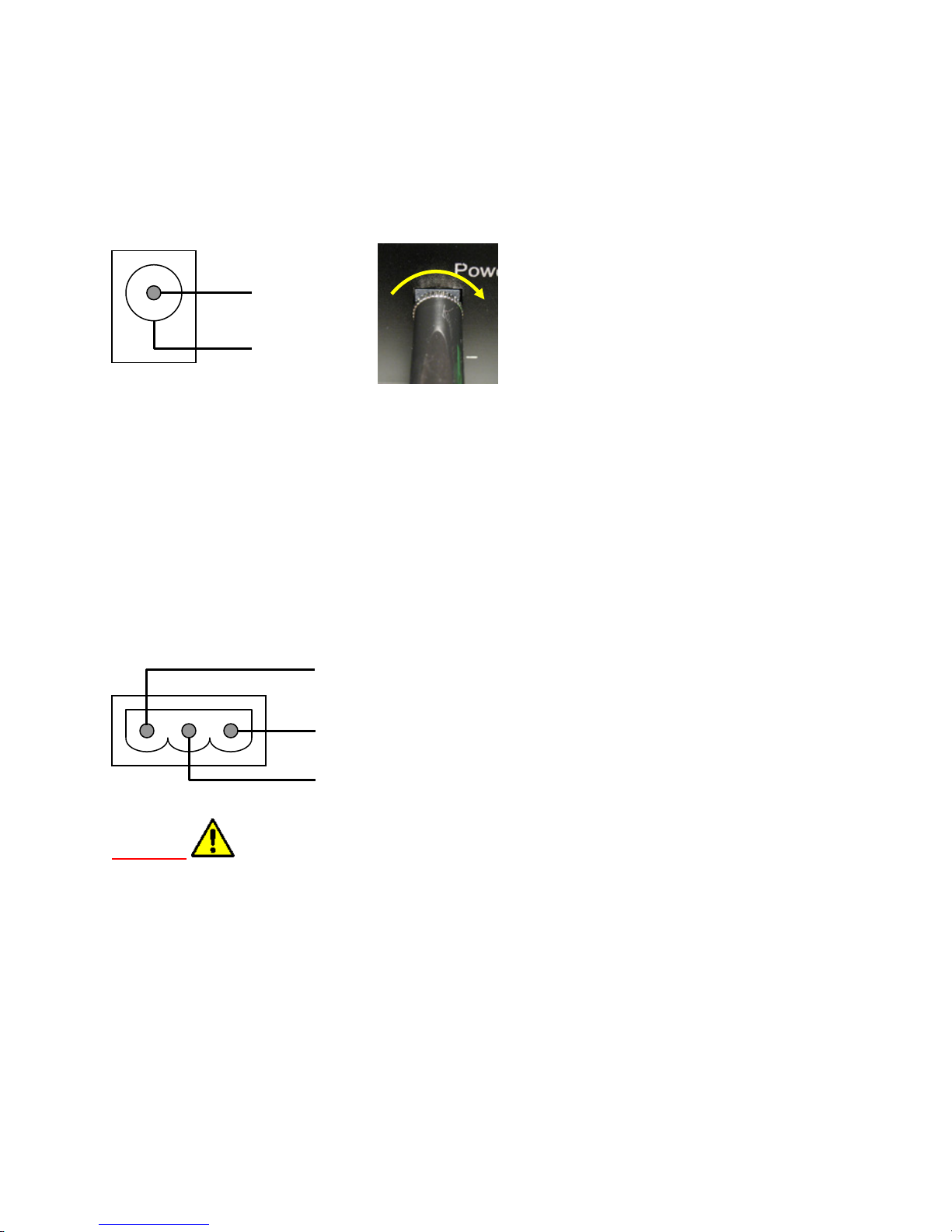

5. DC Input Power Connection and Options............................................................................... 6

5.1 PWR1 port................................................................................................................... 7

5.2 PWR2 port................................................................................................................... 7

5.2.1 PWR2 for DC input ............................................................................................... 7

5.2.2 PWR2 for DC output (consult technical support before using this configuration)... 7

6. Setting Signal Routing............................................................................................................. 8

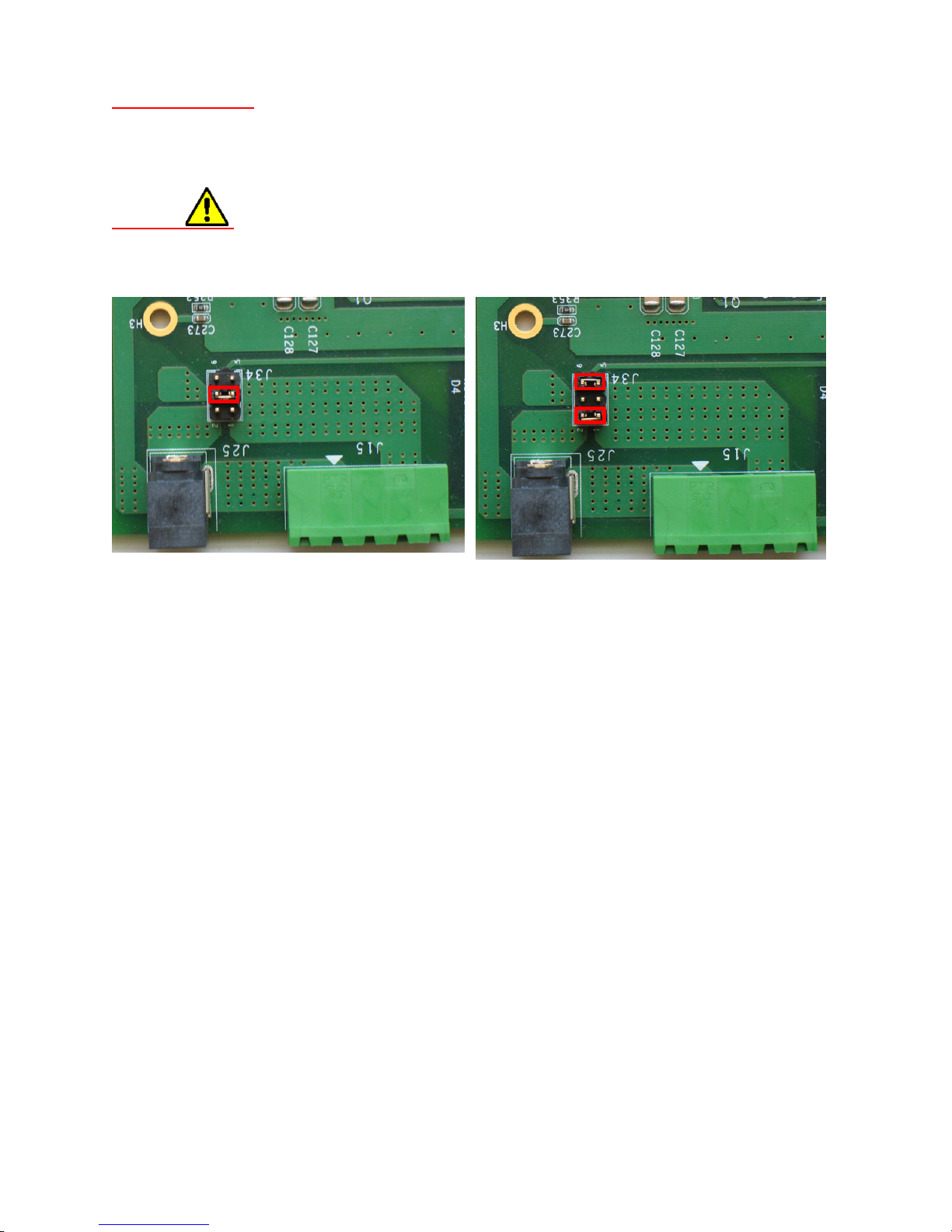

6.1 DIP Switches ............................................................................................................... 8

6.1.1 Image DIP switch.................................................................................................. 8

6.1.2 CC1~CC4 and SerCom DIP switches................................................................... 8

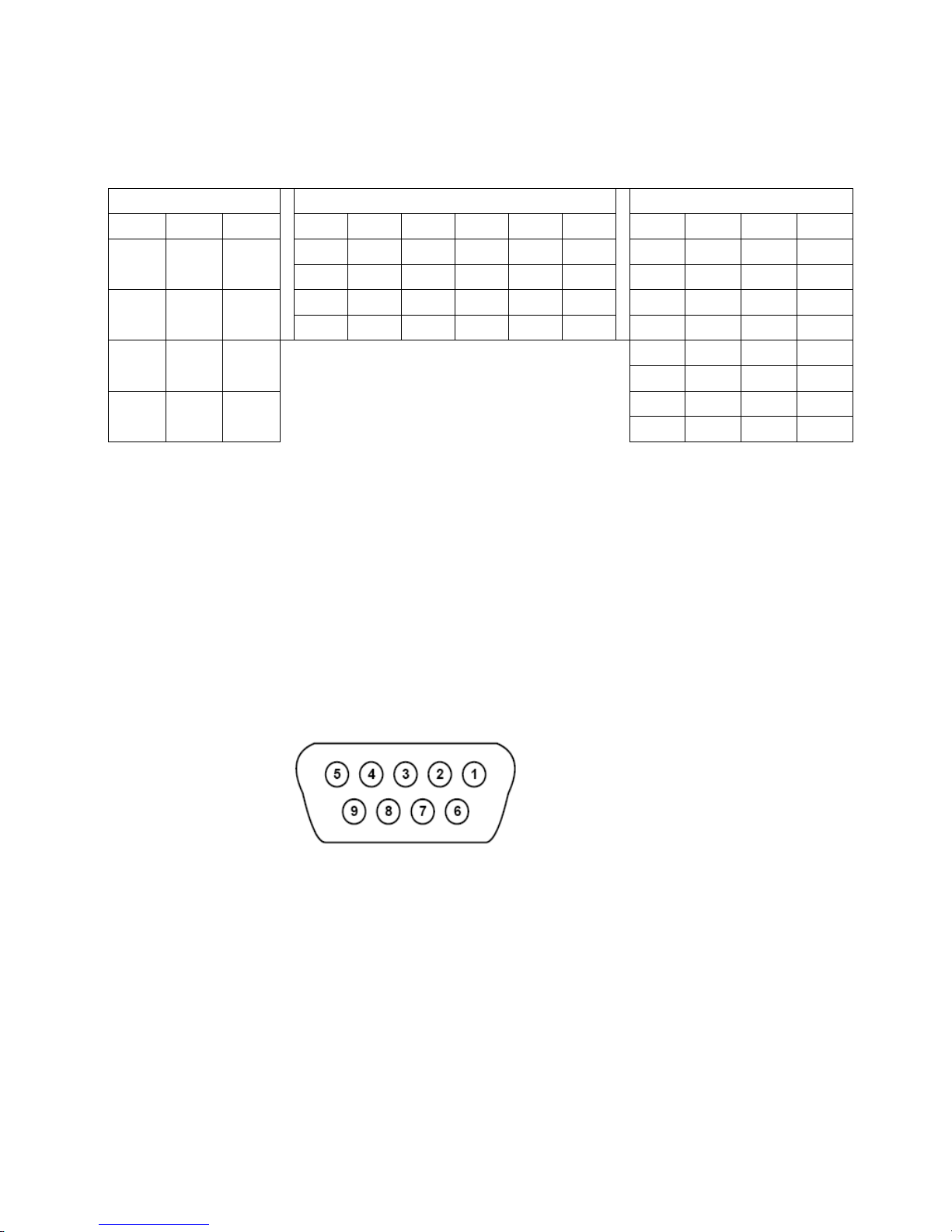

6.2 RS232 port .................................................................................................................. 9

6.2.1 Pin assignment..................................................................................................... 9

6.2.2 Shift register settings ............................................................................................ 9

6.2.3 Programming Commands....................................................................................11

6.2.4 Hyper Terminal Setup..........................................................................................11

6.2.5 Programming Examples Using Hyper Terminal....................................................13

7. LED Indicators ...................................................................................................................... 14

8. Specifications......................................................................................................................... 15

8.1 General Specification..................................................................................................15

8.2 Camera Link Interface.................................................................................................15

8.3 Mechanical Dimensions (mm).....................................................................................15

9. Contact Us ............................................................................................................................. 16

TABLES

Table 1. CC1~CC4 and SerCom DIP switch settings................................................................. 9

Table 2. Relationship between the hex command numbers and shift register settings..............11

Table 3. Commands for setting the shift registers .....................................................................11

Table 4. Definition of the 1x3 LED indicator ..............................................................................14

FIGURES

Figure 1. Block Diagram of PHANTA-S1F4................................................................................ 4

Figure 2. Block Diagram of PHANTA-D2B4 ............................................................................... 5

Figure 3. Block Diagram of PHANTA-S1B8................................................................................ 6

Figure 4. Simplified DC input circuit diagram (not for PWR2 as an output)................................. 6

Figure 5. Jumper settings for PWR2 .......................................................................................... 8

Figure 6. RS232 Port Pin Assignment (DB9 Female)................................................................. 9

Figure 7. Settings of the COM port property for the Hyper Terminal..........................................12

Figure 8. ASCII Settings for Hyper Terminal. ............................................................................13

Figure 9. Starting message when RS232 communication is successfully established...............13