TIPS ON FAULT FINDING, FUNCTIONAL IRREGULARITIES

AND THEIR ELIMINATION

.~.~.

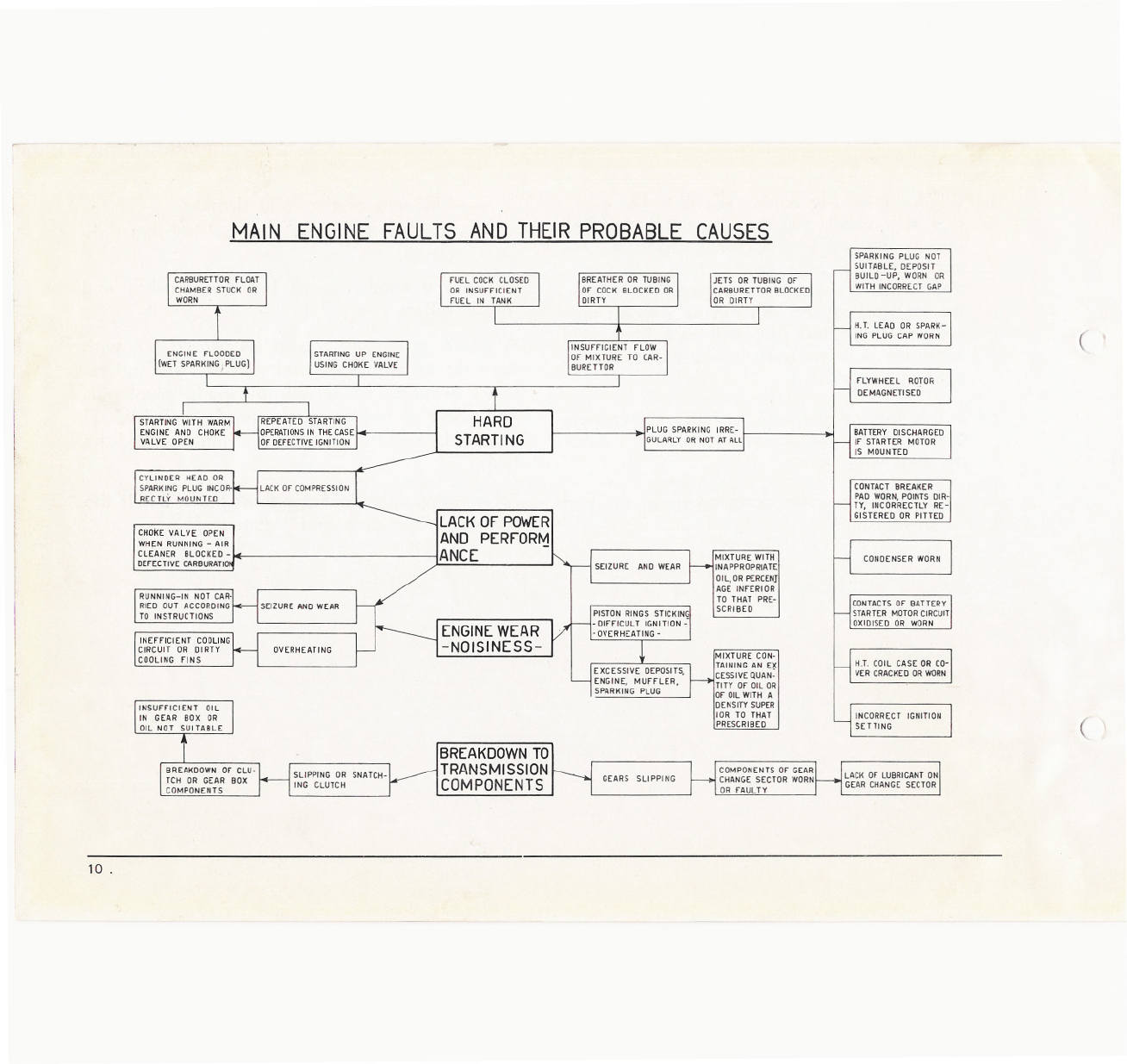

1. . Engine

a) On page 10 is a summary of the engine faults

- most commonly verified during operation: ie,

ignition, fuel feed, carburation and lubrication.

For a normal adjustment or registration pro-

ceed according to the following instructions:

- In the case of poor performance, low com-

pression and pressure losses, check that the

engine groups in question are well secured

in position.

- On changing sparking plugs ensure that

the type prescribed in the booklet « Ope-

ration and Maintenance» are used. The

spark gap between the electrodes should

always be set at 0.6 mm (0."023).

- The gap between contact breaker points

should always come between the limits of

0.4 and 0.5 mm (0".015 and 0".019).

Spark advance: For for mods AC 1 and

AC 2; 28° :t: 1° for Mod. AC 3 25° :t: 1°.

- Groups clutch, gear change, should be ac-

curately checked for play with respect to

their relative cables (see pages 38 -;- 39

and control levers. In the case of clutch

slipping, check springs and plates and for

the gear box, control the parts comprising

the transmission in correspondence to the

selector quadrant.

r)

b) On stripping down or overhauling engine

groups, always use new split pins and gaskets

on re-assembly.

c) In the case where faults are verified which do

not enter under those indicated on the chart

at pag. 10, eg: abnormal engine noises, brea-

kages or premature wear to moving parts etc.)

it is necessary to localize the fault and substi-

tute or overhaul the part according to the con-

ditions prevailing: please note that the as-

sembly play of the main engine components

(piston-cylinder, piston rings etc.) should cor-

respond to those indicated on the table from

page 29 onwards.

)

6.