Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

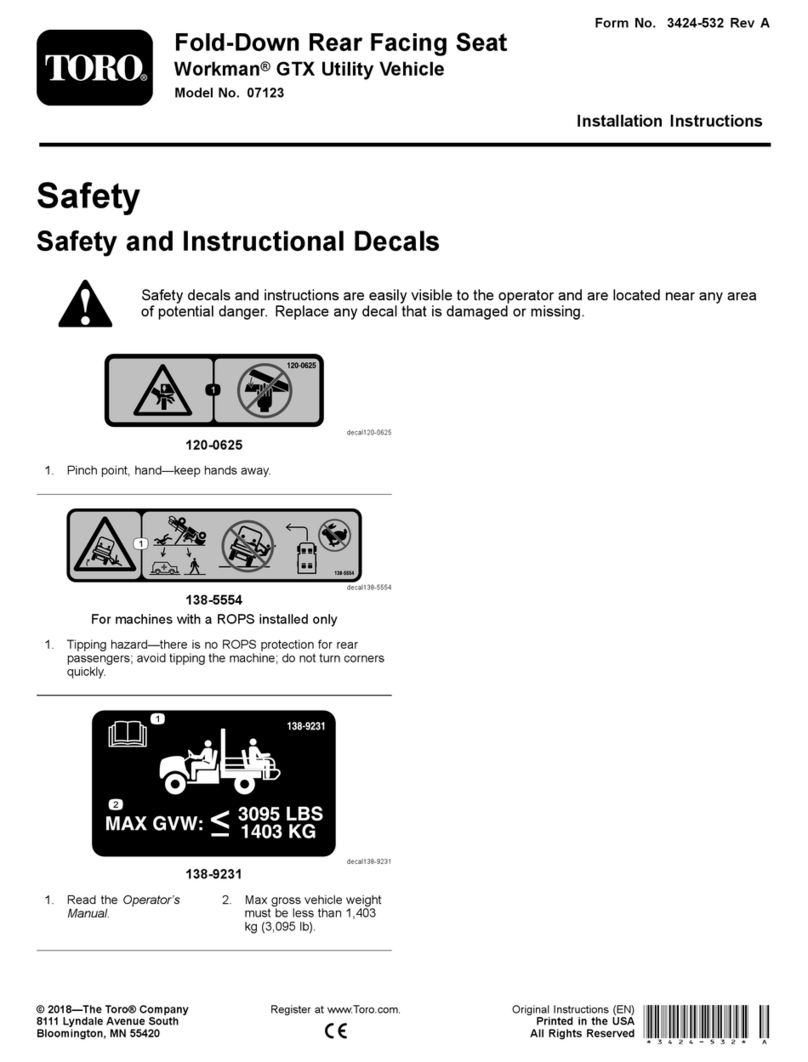

Safety and Instructional Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 Installing the Steering Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Connecting the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Checking the Fluid Levels and T ire

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Burnishing the Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Reading the Manual and V iewing the

Setup Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Attachments/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Performing Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Checking the T ire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adding Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Breaking in a New Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

During Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating the Cargo Bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Stopping the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Loading the Cargo Bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

After Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

After Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Hauling the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

T owing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

T owing a T railer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Recommended Maintenance Schedule(s) . . . . . . . . . . . 26

Daily Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintaining the Machine under Special

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pre-Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preparing the Machine for Maintenance . . . . . . . . . . . . 29

Lifting the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Accessing the Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Greasing the Front Wheel Bearings . . . . . . . . . . . . . . . . . . 30

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Engine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Servicing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Servicing the Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Servicing the Spark Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Adjusting the High/Low Idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Inspecting Fuel Lines and Connections . . . . . . . . . . . . . 37

Replacing the Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Servicing the Carbon Canister . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Electrical System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Servicing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Maintaining the Headlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Drive System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Maintaining the T ires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Inspecting the Steering and Suspension

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Adjusting the Front Wheel Alignment . . . . . . . . . . . . . . . . 46

Checking the T ransaxle-Fluid Level . . . . . . . . . . . . . . . . . . 47

Changing the T ransaxle Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Checking and Adjusting Neutral . . . . . . . . . . . . . . . . . . . . . . . . 48

Maintaining the Primary Drive Clutch . . . . . . . . . . . . . . . . 48

Reducing the T op Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cooling System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cooling System Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Cleaning the Engine-Cooling Areas . . . . . . . . . . . . . . . . . . 50

Brake Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Inspecting the Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Adjusting the Parking-Brake Handle . . . . . . . . . . . . . . . . . 50

Adjusting the Brake Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Checking the Brake-Fluid Level . . . . . . . . . . . . . . . . . . . . . . . . 52

Changing the Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Belt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Servicing the Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Adjusting the Starter-Generator Belt . . . . . . . . . . . . . . . . . 53

Chassis Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adjusting the Cargo-Bed Latches . . . . . . . . . . . . . . . . . . . . . 54

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

W ashing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Storage Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Storing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4