Page 1.2

SECTION 1 - TECHNICAL SPECIFICATION

LXI 2-POLE HIGH VOLTAGE MATRIX 60-311

pickering

LXI 2-Pole High Voltage Matrix – 60-311

pickeringtest.com

Overview

“Hot” Switching

This is when the load is switched with the high

voltage source applied. Hot switching may generate

considerable RFI, both within the switching module and on

interconnecting wiring. Care must be taken to suppress or

shield all cabling.

Note that any precaution which adds extra capacitance to

a cable should be taken with great care, even a very small

capacitance at high voltages can cause very large inrush

current through the module resulting in possible switch

weld and excessive RFI.

The 60-310 modules include extensive built-in RFI

suppression circuits that minimize RFI and surge problems.

“Cold” Switching – The Preferred Option for Reliability & Long Life.

With cold switching, the relay is operated before the high voltage

source is applied. In this case the maximum carry current is much

greater, also there will be much less stress on the reed relays, resulting

in improved reliability and life.

Most high voltage sources include a soft start facility which reduces the

likelihood of generating RFI or temporary over-voltage.

High voltage switching modules are often used for isolation testing

applications (e.g. cable, transformer or semiconductor isolation tests),

in these cases, cold switching is nearly always the preferred option to

reduce the risk of high voltage transients that may cause premature

breakdown.

Overview of “Hot” & “Cold” Switching Techniques

Y1

Y2

Y3

Y4

X74

X75

X1

X3

X2

X4

X BUS LOOP-THRU

ISOLATION

SWITCHES

75x4 2-POLE MATRIX #1

X149

X150

X76

X78

X77

X79

X BUS LOOP-THRU

ISOLATION

SWITCHES

75x4 2-POLE MATRIX #2

X224

X225

X151

X153

X152

X154

X BUS LOOP-THRU

ISOLATION

SWITCHES

75x4 2-POLE MATRIX #3

Female to Female

9-pin D-type

Loop-Thru Cable

Female to Female

9-pin D-type

Loop-Thru Cable

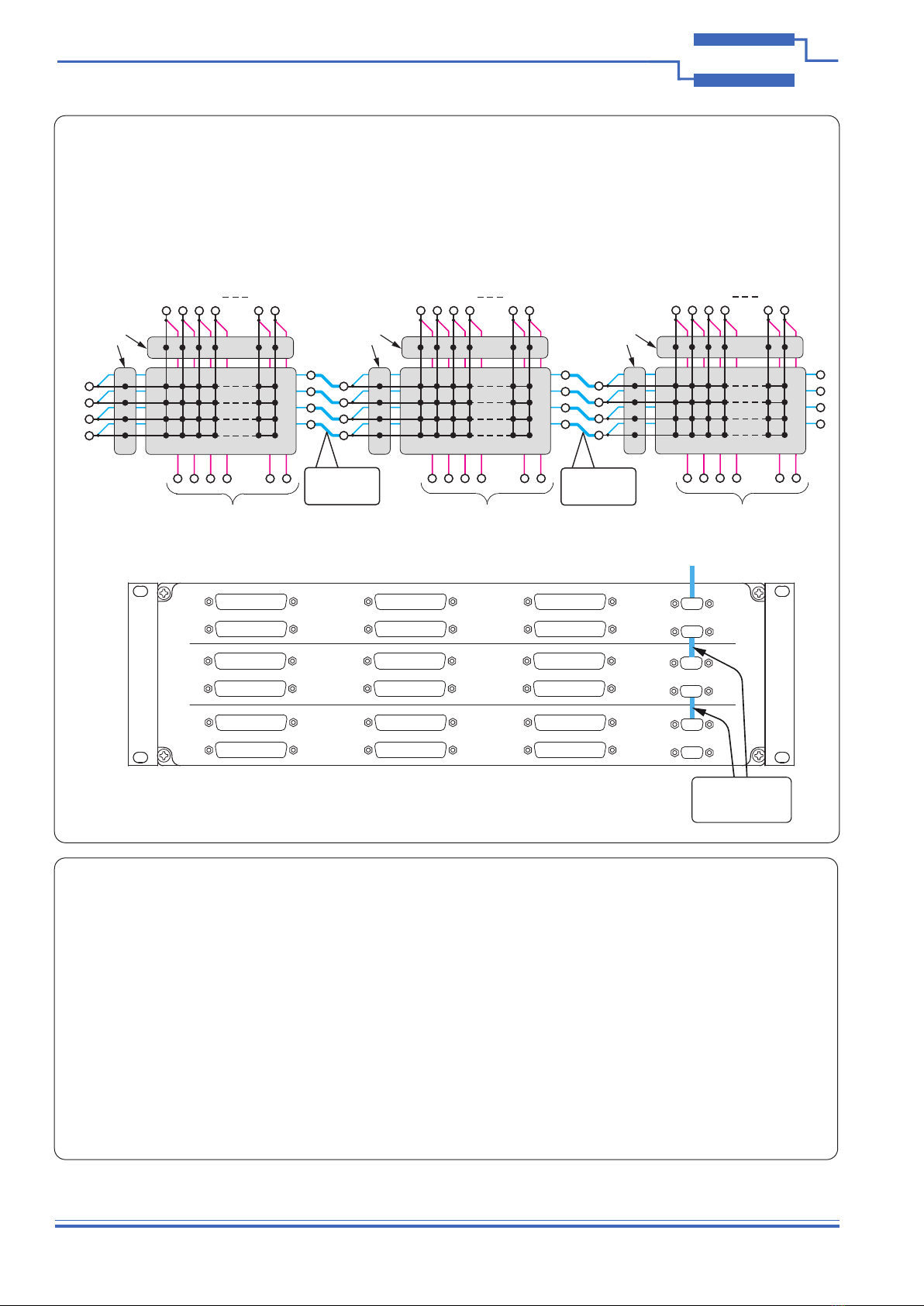

Matrix Expansion

The 60-311 may be expanded to larger matrix sizes by using cabling to daisy-chain the Loop-Thru connections.

The illustrations below show the three 75x4 matrices of a 60-311-003 interconnected as a single 225x4 matrix using female to female

9-pin D-type cables to link the Y buses. In the same way, the X Loop-Thru connections can be used to interlink the X signals and create

a matrix with a wider Y bus. Additionally, the Loop-Thru connections can be used to link X and Y buses between units. For example, ten

75x4 matrices housed in four separate 60-311 units can have their Y buses daisy-chained to produce a single 750x4 matrix.

The rst diagram shows the matrix schematic and the second diagram shows how the front panel connectors are cabled together.

X1-25 X26-50 X51-75

X76-100 X101-125 X126-150

X151-175 X176-200 X201-225

Y1-4

Female to Female

9-pin D-type

Loop-Thru Cables

Diagram showing the front panel cabling required to interconnect three 75x4 matrices

as a single 225x4 matrix. The Y-bus Loop-Thru connections can be

further expanded to other 60-311 Units.

Schematic diagram of three 75x4 matrices connected as a single 225x4 matrix

using the Y-bus Loop-Thru connections.