Page 1.2 PXI PROGRAMMABLE POWER SUPPLY 41-743

pickering

SECTION 1 - TECHNICAL SPECIFICATION

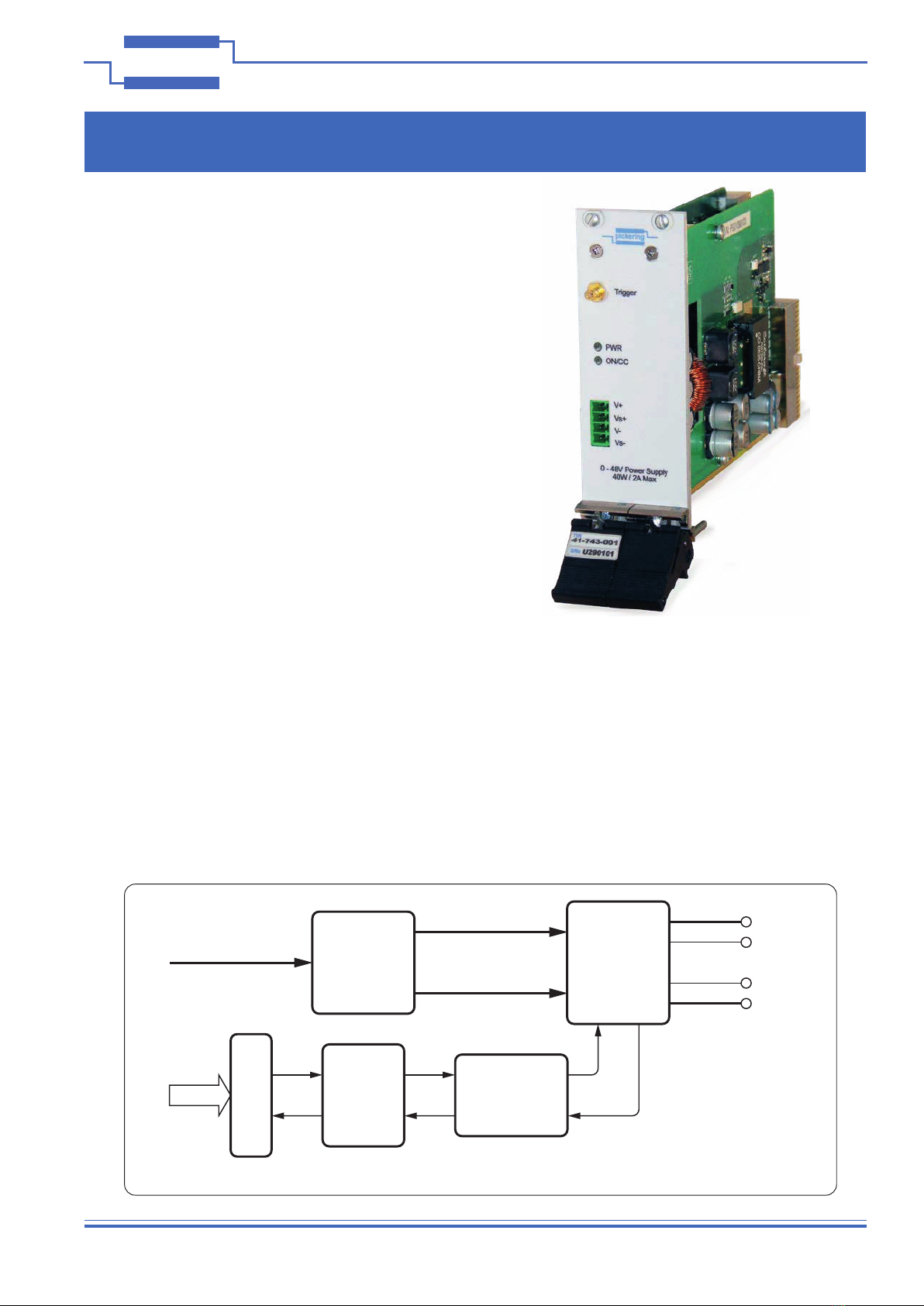

Programmable Power Supply 48 V, 41-743

pickeringtest.com

Specifications

Specification

Output Voltage

Range:

0 V to 48 V,

0.74 mV nominal resolution.

Output Voltage

Accuracy:

±0.2 % ±25 mV.

Voltage Slew Rate: 1 V/ms nominal at full load

Output Noise: 1.5 mVrms, 6 mV peak to peak, full load,

DC to 1 MHz.

Output Current

Range:

2 A to 20 V, de-rating linearly to

0.8 A at 48 V.

Current Limit: 0 to 2 A, 34 µA nominal resolution.

Current Limit

Accuracy:

±0.5 % of set value ±10 mA.

Voltage Sense: Voltage sense lines compensate for up

to 0.5 V voltage drop (0.25 V for each

connection), can be switched to sense

output voltage on user connector.

Current Monitor: Accuracy: ±0.2 % of reading ±5 mA

Resolution: 35 µA

Voltage Monitor: Accuracy: ±0.1 % of reading ±10 mV

Resolution: 0.74 mV

Isolation Barrier: Designed with ±250 V isolation barrier,

recommended to ±60 V relative to PXI

ground.

>100 MΩ insulation resistance from

voltage outputs to PXI ground.

Trigger Input: Front panel or PXI Trigger Bus.

Permits triggered output changes or

measurements, permits sampled output

measurements at time intervals in

multiple of 100 µs, permits a sequence

of output changes from stored settings.

Minimum trigger width 20 µs.

Front panel trigger input is optically

isolated, maximum input voltage +12 V,

50 mA.

Operating/Storage Conditions

Operating Conditions

Operating Temperature:

Humidity:

Altitude:

0 °C to +55 °C

Up to 90 % non-condensing

5000 m

Storage and Transport Conditions

Storage Temperature:

Humidity:

Altitude:

-20 °C to +75 °C

Up to 90 % non-condensing

15000 m

PXI & CompactPCI Compliance

The module is compliant with the PXI Specification 2.2.

Local Bus, Uses a 33 MHz 32-bit backplane interface.

Safety & CE Compliance

All modules are fully CE compliant and meet

applicable EU directives: Low-voltage safety EN61010-

1:2010, EMC Immunity EN61326-1:2013, Emissions

EN55011:2009+A1:2010.*

Mechanical Characteristics

Dual slot 3U PXI (CompactPCI card).

3D models for all versions in a variety of popular file

formats are available on request.

Connectors

PXI bus via 32-bit P1/J1 backplane connector.

Power supply outputs & sense: 4-pin plug-in screw

terminal block

Trigger Input: SMB coaxial connector.

For pin outs please refer to the operating manual.

41-743 Safe Operational Area

Power Requirements

+3.3 V +5 V +12 V -12 V

750 mA 12 A max

(from 2 slots)

60 mA 0

Current

2.0A

0.8A

Voltage

20V 48V