CP600 Pivot Operators Manual

OPERATION, SAFETY & MAINTENANCE Section 1-5

© Pierce Corporation

July 2010

FINAL CHECKS AND INITIAL OPERATION

The following list of checks and operation procedures should be followed during the ini-

tial start up of the circle. These same basic procedures can also be followed at the initial

start up of each irrigation season.

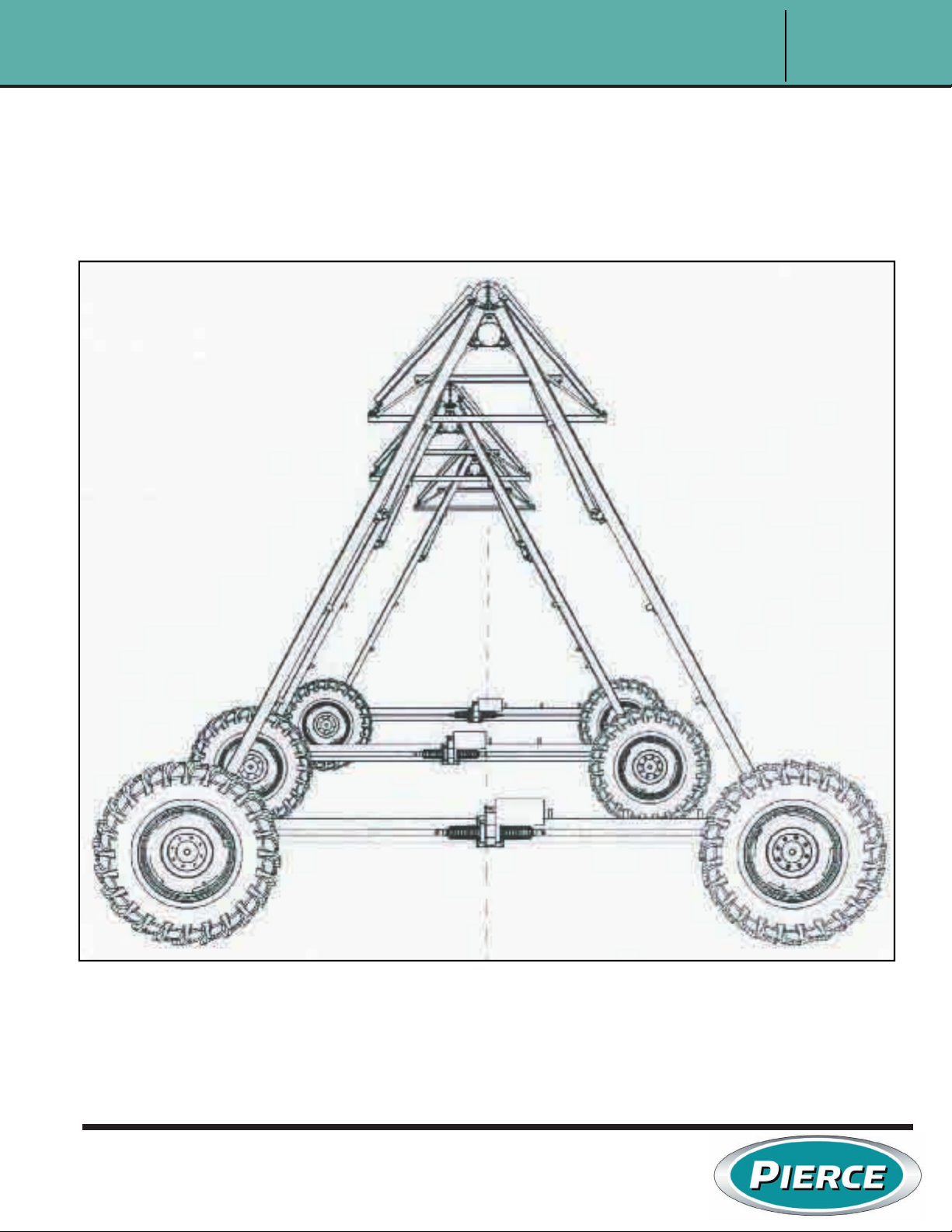

1. Bolts: Check to insure that all bolts have been properly installed and tightened.

2. Grounding: Be sure the machine is properly grounded. Refer to the Getting Started

and Electrical sections for proper main panel grounding.

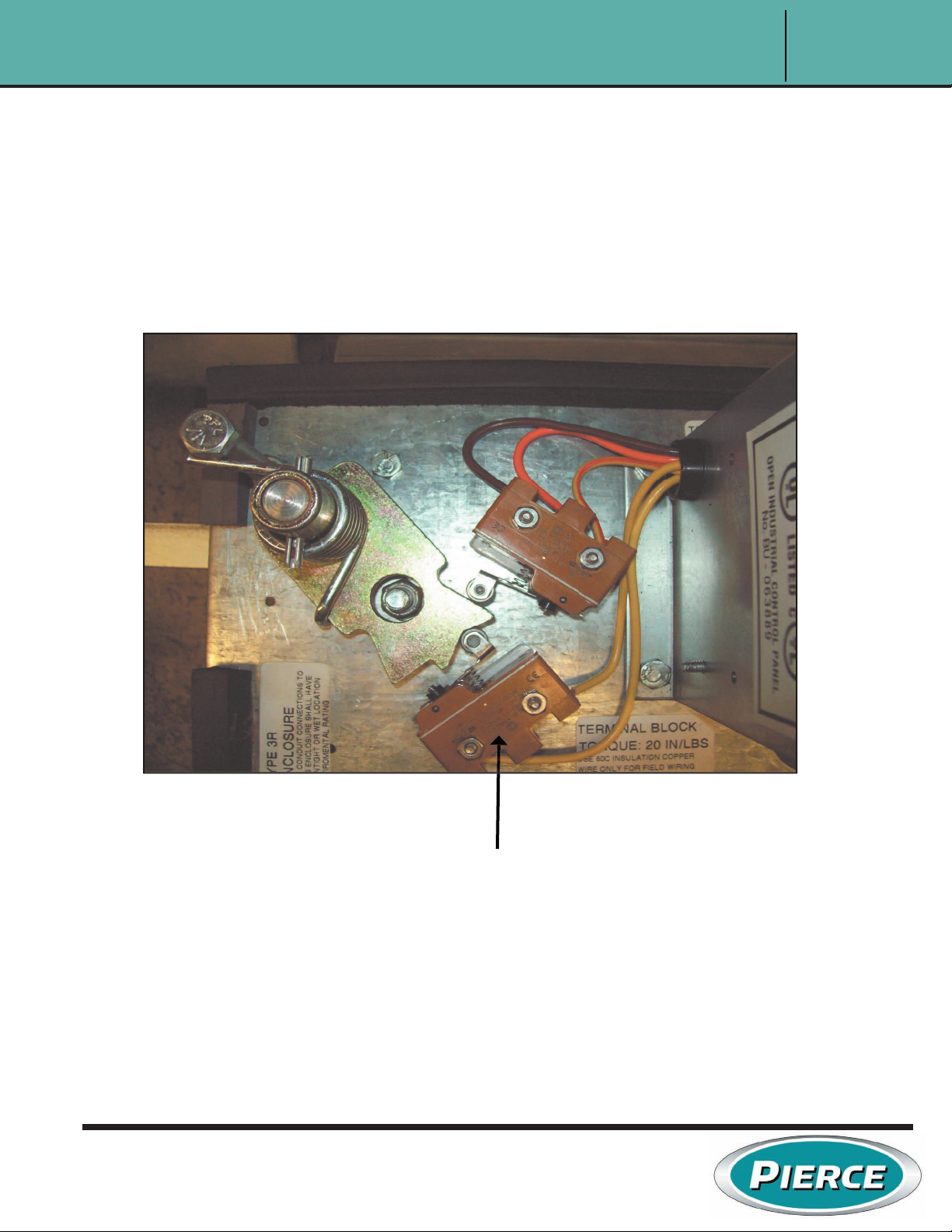

3. Control Limit Switches: The limit switches in the tower junction boxes have been pre-

set at the factory, however, they should be checked according to the procedures out

lined in maintenance section, Control Switch Adjustment.

4. Control rods: Check that all control rods are connected to the cam arm.

5. Alignment: The machine should be in a straight line when erection is completed. Ad

just the control rod so the tower safety limit switch roller is in the middle of the “V” of

the cam. Tighten the adjusting nuts. After the machine is started, fi nal alignment

should be performed according to the procedure in maintenance section, alignment.

6. Voltage: Voltage at the pivot panel should be 480V on all three legs of the power

lines.

Note: Voltage is dependant upon your location. Voltage should not be more than

5% higher or lower than the recommended voltage or damage may occur.

7. Lubrication: Check the oil level in all gearboxes and motors. Grease the two fi ttings

on the pivot elbow until grease is visible at the top and bottom of bearing.

8. Starting: When all the above checks have been made, the machine is ready to start.

Close the main panel inner door and turn the main disconnect switch on. Follow opera

tion instructions outlined in Section 4 Panel Operation.

WARNING MAKE SURE POWER IS DISCONNECTED AT THE MAIN SERVICE

PANEL BEFORE PERFORMING ANY ELECTRICAL SERVICE TO THE

MACHINE OR BEFORE OPENING THE INNER DOOR OF THE MASTER CON

TROL PANEL.

Final Checks and Initial Operation