Dear customer,

Now as you've brought home one of your favorite Pilot spray guns. We'd like to say a special 'thank you'. These

precision-engineered tools have been designed to excel, making every spray job the work of a professional.

As you know Pilot stands for quality, reliability and safety, earned by 6 decades of experience and overwhelming

customer satisfaction. We are certain we have met all safety requirements. Our products bear the identication plate

in conformance to the CE ruling.

To facilitate easy understanding of the working procedures please refer to the detailed instruction manual.

Description

Type - 68 spray guns are easier to use than most spray guns. These lightweight gravity feed spray guns are suitable for production

work on articles of small to medium sizes. They are ideal for spray-painting motorcar bodies, refrigerators, machinery, etc. Perfect

balance, comfortable handle and trigger action makes them easy and non-tiring to operate. The air control valve on the left can easily

control the volume of air.

These gravity feed spray guns are supplied with a 0.14 lit. Gravity cup.

Important: These guns are not designed to be used with highly corrosive or highly abrasive coating materials. Violation may increase

the need for thorough cleaning and /or the necessity for replacement of parts. If there is any doubt regarding the suitability of a

specic material you may seek advice and /or submit a sample for test.

Training

Personnel should be given adequate training in the safe use and maintenance of this equipment. Training courses on all aspects of

the equipment are available. For details contact your local representative. The instructions and safety precautions contained in this

literature and the literature supplied with the coating material should be read and understood before the equipment is used.

Misuse

All spray guns project particles at high velocity and must never be aimed at any part of the body.

Never exceed the recommended safe working pressures for any of the equipment used.

The tting of non-recommended or non-original accessories or spare parts may create hazardous conditions.

Before dismantling the equipment for cleaning or maintenance, all pressures, air and material, must be isolated and released.

The disposal of non-metallic materials must be carried out in an approved manner. Burning may generate toxic fumes. The removal of

waste solvents and coating materials should be carried out by an authorized local waste disposal service.

The materials used in the construction of this equipment are (bearing in mind the warning on Halogenated Hydrocarbons) solvent

resistant enabling the equipment to be cleaned using gun washing machines. However, this equipment must not be left inside the

gun washing machine for prolonged periods of time after the automatic cleaning cycle has been completed. The solvents used in the

gun washing machine should be regularly checked to ensure that the equipment is not ushed through with contaminated material.

Follow the recommendations of the machine manufacturer.

Installation

Important: To ensure that this equipment reaches you in rst class condition, protective coatings, rust inhibitors, etc. have been used.

Flush all equipment through with a suitable solvent before use to remove these agents from the material passages.

Attach the air supply line to the air intake connector (26). An air compressor installed should be close as possible to the gun and

should provide ltered and regulated air.

Recommended air hose sizes:

• Attached air hose connector from a ltered regulated air supply.

• Recommended air supply hose size up to 10meters long (1/4”) bore.

• Attach the gravity feed cup to the material inlet and ensure that the sealing washer is compressed.

Operation

Mix, prepare and strain the coating material to be sprayed according to the paint manufacturer's instructions. Use a lint free mesh to

strain the material.

• Fill the gravity feed cup with the material. Do not overll. Ensure that the vent hole in the cup lid is clear.

• Adjust the atomizing air pressure to 1-2.5 kgs/sq.cm. (14 to 36 p.s.i.).

• It requires air about (2 - 4 c.f.m.) 55 - 115 liter per minute depending on the liquid to be sprayed.

• Close the needle adjusting screw by turning clockwise.

• Turn on the air at the source of supply and spray test area by turning the needle adjusting screw counter-clockwise until a full coat

is obtained.

If the nish is too sandy and dry, increase the ow of the coating material supply by turning the needle adjusting screw counter-

clockwise.

Increasing or decreasing the atomizing air pressure can also correct both the above. The most efcient atomizing air pressure is the

lowest possible air pressure that will give the desired effect.

The gun should be held perpendicular to the spray surface at all times. Do not arc the gun as this produces an uneven coat of paint.

The recommended spraying distance is 230mm (9”).

Preventive Maintenance

Cleaning

• Turn off air supply and release pressure.

• Empty surplus coating material from cup and clean.

• Remove air cap and clean by immersing in solvent, brush or wipe clean. If any holes in the air cap are blocked use a toothpick or

broom straw to remove the obstruction. Never use a steel wire or hard implement which will damage the air cap and result in a

distorted pattern.

Lubrication

Lubricate all moving parts daily with a few drops of light oil and occasionally place a light coating of Vaseline on the needle spring.

The packing may need to be oiled occasionally to keep them pliable.

Replacement of Parts

1) Needle valve (6)

• Remove needle adjusting screw (9), needle spring (8) needle spring box (7) and needle valve (6). Replace any worn or damaged

parts ensuring that the needle valve seats correctly in the nozzle then adjust packing with needle packing nut (5) so that the

movement of the needle is not restricted.

2) Packing (4)

• Remove needle valve (6) as 1 above.

• Remove trigger (19) and link (15) by unscrewing (17 & 18) and air valve locking nut (16).

• Remove needle packing nut (5) and packing (4). Replace any worn or damaged parts and re-assemble, reversing steps 1 and 2.

Adjust packing so that the movement of the needle is not restricted.

3) Air Valve Pin (10) Packing (4)

• Remove needle valve (6) as 1 above.

• Remove air valve locking nut (16), pull trigger (19) and swing link (15) away, and unscrew air valve packing box (12) and remove

air valve spring (11), air valve pin (10), washers (13 & 14) and packing (4). Replace any worn or damaged parts and re-assemble

reversing step 3.

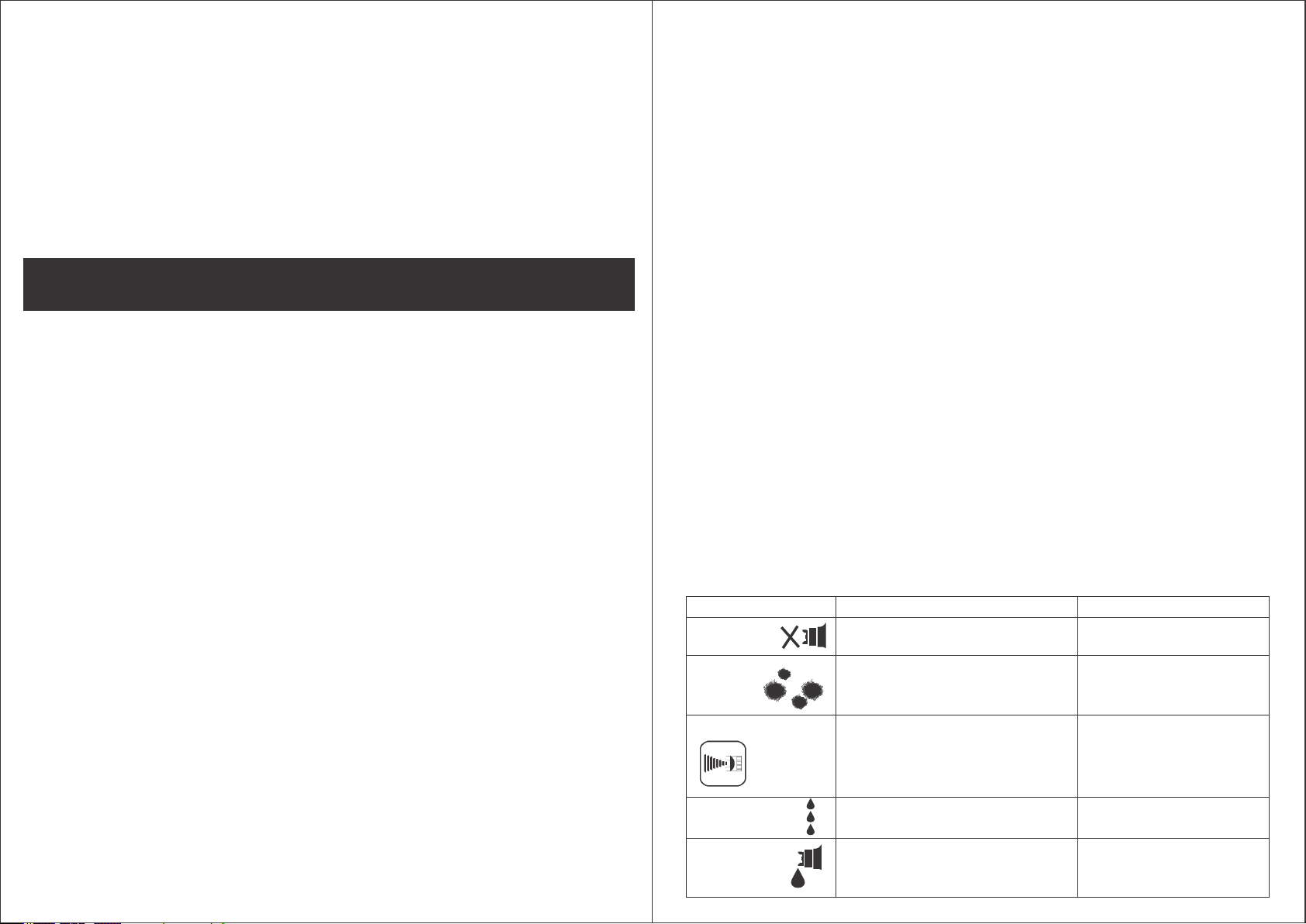

Service Checks - Troubleshooting

C au s e R em e d y

Uneven spray 1. Material build up on air cap/nozzle

2. Coating material flow or viscosity incorrect

1. Clean air cap / nozzle

2. Adjust needle adjustment screw,

or Reduce viscosity

Intermittent spray 1. Insufficient material in cup

2. Gun material passage blocked

3. Loose or damaged nozzle

4. Needle sealing damage.

1. Fill cup

2. Clean

3. Tighten or replace

4. Replace

Fluid leakage

from packing nut

1. Needle packing damage 1. Replace packing.

Dripping from

the nozzle

1. Damaged nozzle or needle

2. Foreign substances between

nozzle and needle prevent sealing

1. No pressure at the gun

2. Needle Adjusting Screw not properly adjusted.

1. Check air supply

2. Adjust

Fault

Not spraying

1. Replace

2. Clean needle and nozzle in thinner

or Replace.