Contents

Operating Manual SDD ES ETH

1003824-EN-06 | 3

Introduction ............................................................................................................................ 5

Validity of documentation.......................................................................................................... 5

Using the documentation .......................................................................................................... 5

Definition of symbols................................................................................................................. 5

Overview ................................................................................................................................. 6

Scope of supply ........................................................................................................................ 6

Unit features ............................................................................................................................. 6

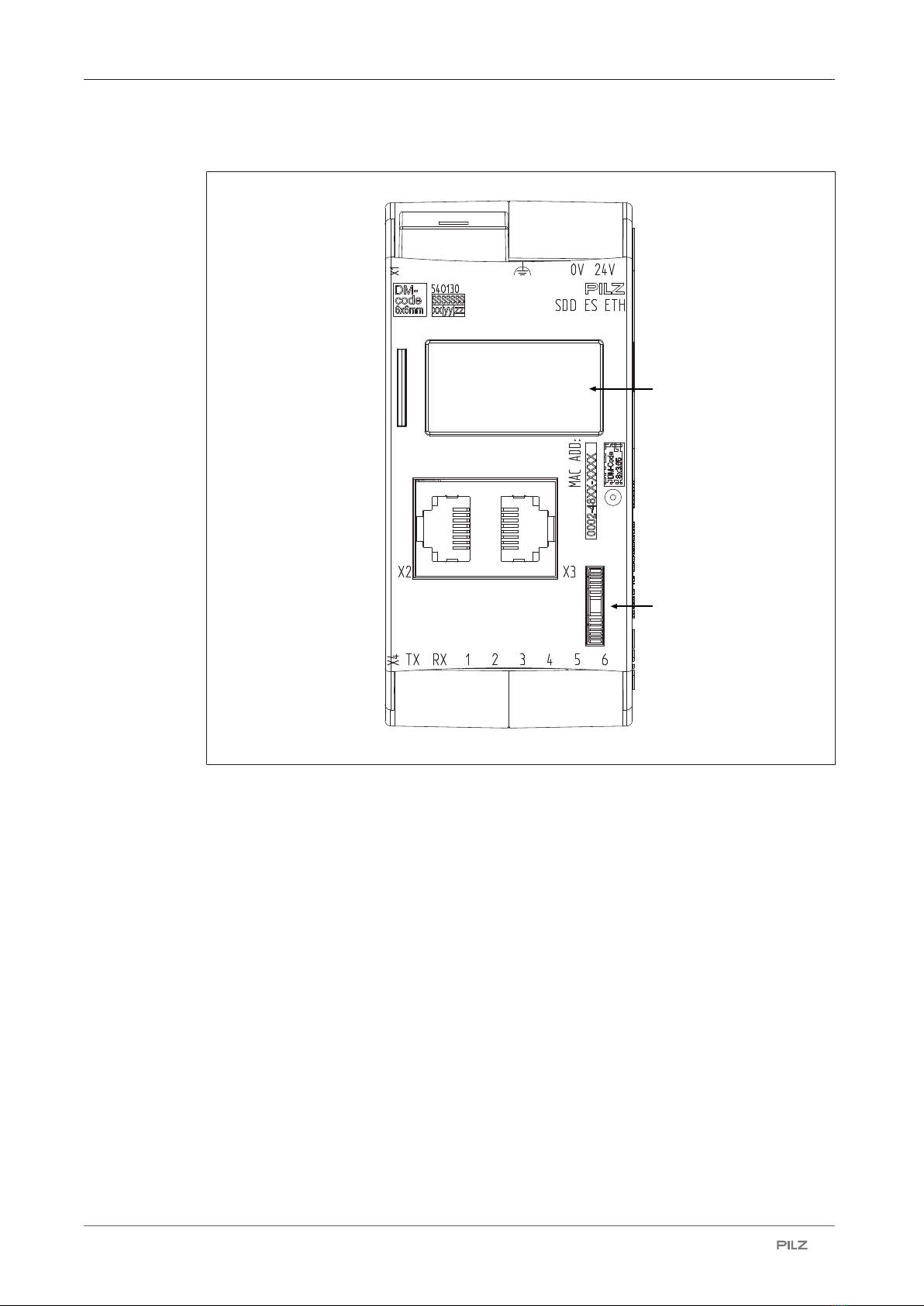

Front view ................................................................................................................................. 7

Safety ...................................................................................................................................... 8

Intended use ............................................................................................................................. 8

Safety regulations ..................................................................................................................... 9

Additional documents that apply............................................................................................... 9

Use of qualified personnel ........................................................................................................ 9

Warranty and liability ................................................................................................................ 9

Disposal .................................................................................................................................... 9

Security ................................................................................................................................... 10

Implemented security measures............................................................................................... 10

Required security measures ..................................................................................................... 10

Function description ............................................................................................................. 11

Operation .................................................................................................................................. 11

Data structure ........................................................................................................................... 12

Block diagram ........................................................................................................................... 12

Installation .............................................................................................................................. 13

Commissioning ...................................................................................................................... 13

General wiring guidelines ......................................................................................................... 13

Ethernet interfaces.................................................................................................................... 13

RJ45 interfaces ("Ethernet") ..................................................................................................... 13

Requirements of the connection cable and connector.............................................................. 14

Interface configuration .............................................................................................................. 14

RJ45 connection cable ............................................................................................................. 14

Process data exchange ............................................................................................................ 15

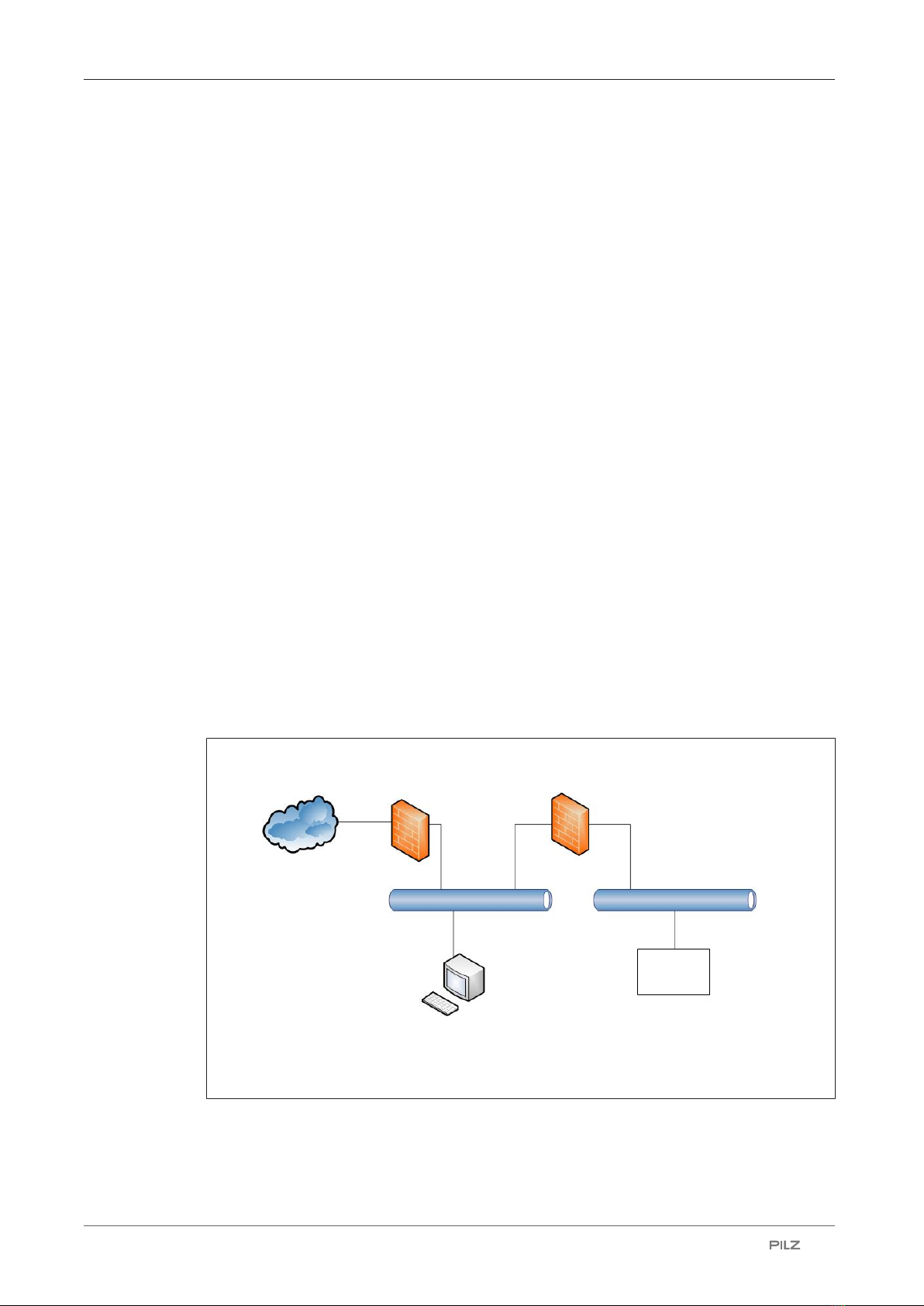

System structure....................................................................................................................... 16

Set IP address .......................................................................................................................... 16

Operation ................................................................................................................................ 17

Display ...................................................................................................................................... 18

Structure ................................................................................................................................... 18

Operate menu........................................................................................................................... 19

Menu structure.......................................................................................................................... 19

Menu settings ........................................................................................................................... 20

Device History menu................................................................................................................. 21

Device Info menu...................................................................................................................... 22