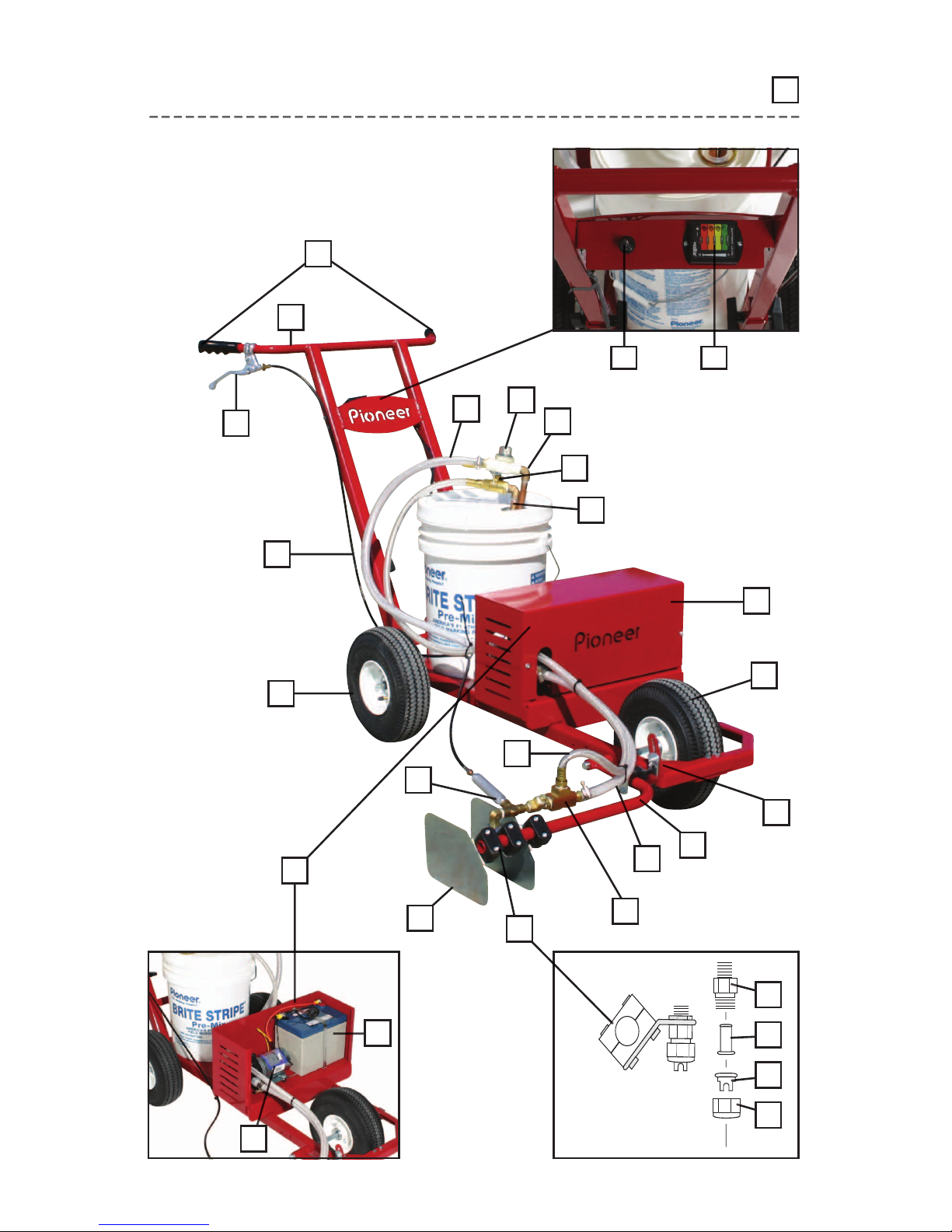

PUMP | PRESSURE SWITCH 8

Pump Precautions:

CAUTION “Intermittent Duty” is dened as; operated and/or frequently start-

ed within a period of time that would cause the motor to reach its maximum

thermal limits. Once the maximum thermal limit is obtained, the motor must

be allowed to return to ambient temperature before resuming operation.

DO NOT use to pump ammable liquids. Never operate the pump in

an explosive environment. Arcing from the motor brushes, switch or

excessive heat from an improperly cycled motor may cause an explosion.

DO NOT assume uid compatibility. If the uid is improperly matched

to the pumps’ elastomers, a leak may occur. Pumps used to transfer

hazardous or hot (max. temeperature 170˚F {76˚C} viton only) chemicals

must be in a vented area to guard against the possibility of injury due to

harmful or explosive liquid/vapors.

DO NOT operate the pump at pressures which cause the motor to

exceed the amperes rating indicated on the name plate. Various pump

models are equipped with thermal breakers to interrupt operation due

to excessive heat. Once the temperature of the motor is within proper

limits it will automatically reset and the pump will start operation without

warning.

CAUTION To prevent electrical shock, disconnect power before

initiating any work. In the case of pump failure, the motor housing

and/or pumped uid may carry high voltage to components normally

considered safe.

Pressure Switch Operation:

The pressure switch reacts to outlet pressure, and interrupts power at

the preset shut-off pressure indicated on the pump label. When outlet

pressure drops below a predetermined limit (typically 15-20 PSI.{1-1.4

bar} less than the shut-off pressure) the switch will close and the pump

will operate until the shut-off (high) pressure is achieved. The shut-off

pressure is set to factory calibrated standards. See the motor label for

specic pump specications.

CAUTION Improper adjustment of the pressure switch may cause se-

vere overload or premature failure. Failures due to improper adjustment

of the pressure switch will not be covered under the limited warranty.

If the ow rate is very low, the pump may re-pressurize the outlet faster

than the uid is being released, causing rapid cycling (On/Off within

2 seconds). If the pump is subjected to rapid cycling during normal

operation, or for infrequent periods, damage may occur.