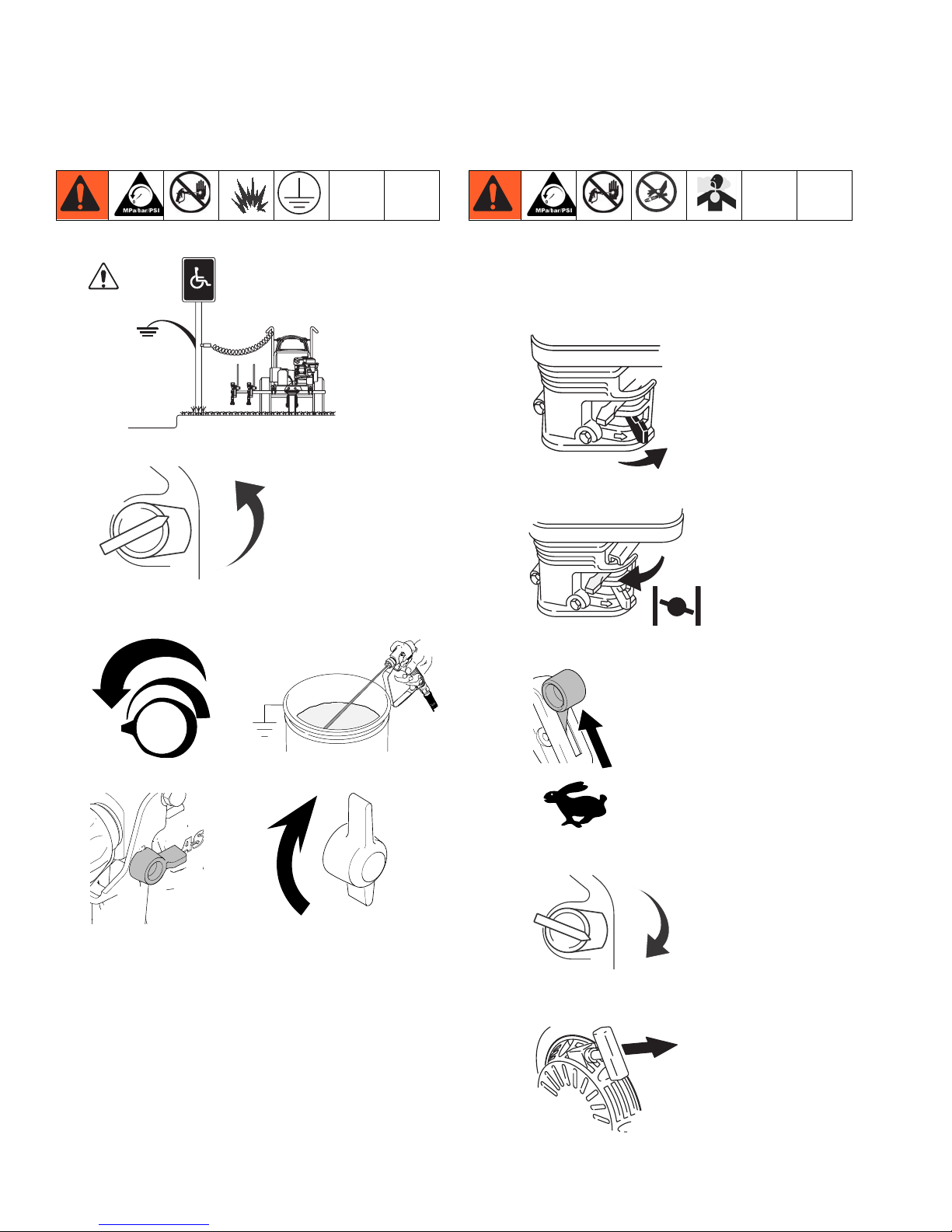

Warnings

43A0441A

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

•Read MSDSs to know the specific hazards of the fluids you are using.

•Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a cut,

but it is a serious injury that can result in amputation. Get immediate surgical treatment.

•Do not spray without Uni-Tip Guard and trigger guard installed.

•Engage trigger lock when not spraying.

•Do not point gun at anyone or at any part of the body.

•Do not put your hand over the Uni-Tip.

•Do not stop or deflect leaks with your hand, body, glove, or rag.

•Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or servic-

ing equipment.

•Tighten all fluid connections before operating the equipment.

•Check hoses and couplings daily. Replace worn or damaged parts immediately.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

•Do not touch hot fluid or equipment.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

•Keep clear of moving parts.

•Do not operate equipment with protective guards or covers removed.

•Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow

the Pressure Relief Procedure and disconnect all power sources.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this warning can result in death, serious injury, or property

damage.

•Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents.

•Many other fluids may contain chemicals that can react with aluminum. Contact your material supplier for

compatibility.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids con-

taining such solvents in pressurized aluminum equipment. Such use can cause serious chemical reaction and

equipment rupture, and result in death, serious injury, and property damage.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of

the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic

fumes, and burns. This equipment includes but is not limited to:

•Protective eyewear, and hearing protection.

•Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

Warnings