3.2 Speed and Time Settings

Speed setting

1. Press RPM/TIME key. The speed

indicator light is lit.

2. Press up and down arrow keys to

access the speed setting state, speed

value starts flashing.

3. Press up and down arrow keys to

change the speed value. Speed

increases or decreases. The minimum

unit is 1rpm.

4. During settings, the unit will reset to

current values if no value is input after

3 seconds.

5. Press “Run/Stop” key to run or stop.

Time setting

1. Press RPM/TIME key. The time

indicator light is lit.

2. Press up and down arrow keys to

access the time setting state. Speed

value starts flashing;

3. Press up and down arrow keys to

change the time value. Time increases

or decreases. The minimum unit is 1

minute or 1 hour.

4. During settings, the unit will reset to

current values if no value is input after

3 seconds.

5. Press “Run/Stop” key to run or stop.

Notes

1. When the shaker is running, the LED

display will switch between the speed

and timer function every 30 seconds

automatically. Press RPM/TIME key to

manually toggle between the speed

and timer value.

2. In “timer mode” the LED display will

show the remaining running time.

3. In “continuous mode” the LED display

will show elapsed run time.

4. After the run is complete, the LED

display will read “end”. Press any key

to place the shaker in standby mode.

3.3 Alarm System

Alarm System

1. During operation, the alarm will sound

after 10 seconds if the unit has not

begun shaking. In addition, the alarm

will sound and stop for the speed over

650 rpm after 2 seconds.

2. Once the shaker begins to alarm, the

RUN indicator light will not be visible

and the WARN indicator light will flash,

and the unit will stop running.

Power failure recovery

When the power supply is cut off

suddenly to the shaker, resulting in a

power failure, the unit will automatically

run at the previous set parameter upon

power restoration.

Section 4 Application

Application on Lab Benches

To operate the shaker outside of a CO2 incubator, refer to Specifications in Section 2.

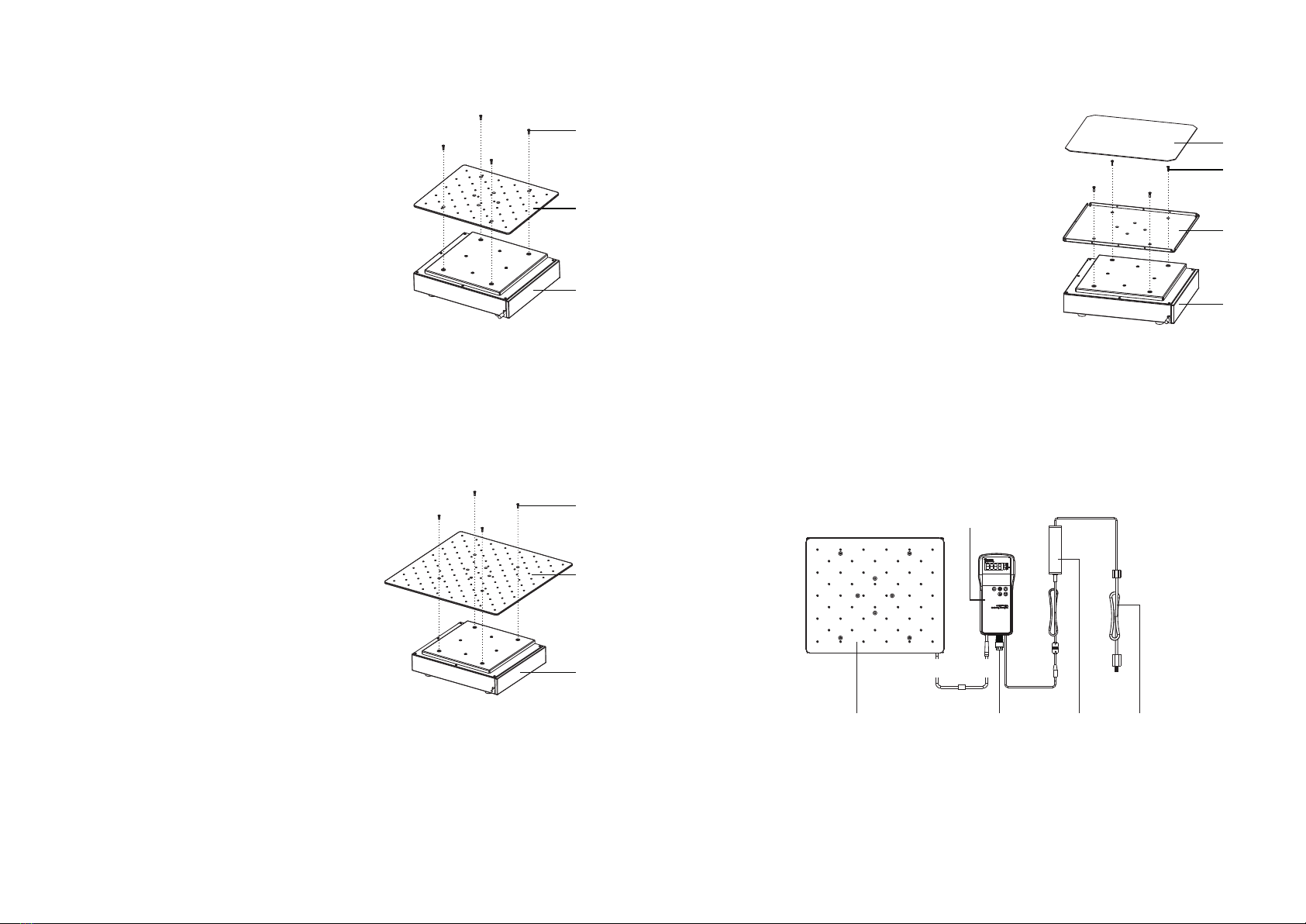

Application in CO2 Incubator

Place the main body of the shaker in the CO2 incubator, and use the

signal cable to connect the control box through the access port of the CO2

incubator. Refer to Figure 4-1.

Warning

1. Never put the control box in the CO2

incubator.

2. The back of control box is magnetized,

and can be attached on the surface of

the CO2 incubator.

3. When the main body of CO2 Resistant

Shaker is in operation in the CO2

incubator, keep a safe distance from

the inner wall of the CO2 incubator to

avoid collisions.

4. The main body of the shaker should

be connected to the control box wire

through the access port of the CO2

incubator.

5. If the cells are sensitive to vibrations,

do not put them in the same incubator

or on the shaker.

11 Section 3 | Operation

Figure 4-1

1) CO2 Incubator

2) Control Box

3) Power Cord

4) Main body of CO2 Resistant Shaker

①

②

③

④

MaxQ 2000 CO2 Plus 12

88883101