i

Table of Contents

Section Title Page

Table of Contents ............................................................................................................................................ i

List of Tables and Figures ...................................................................................................................................ii

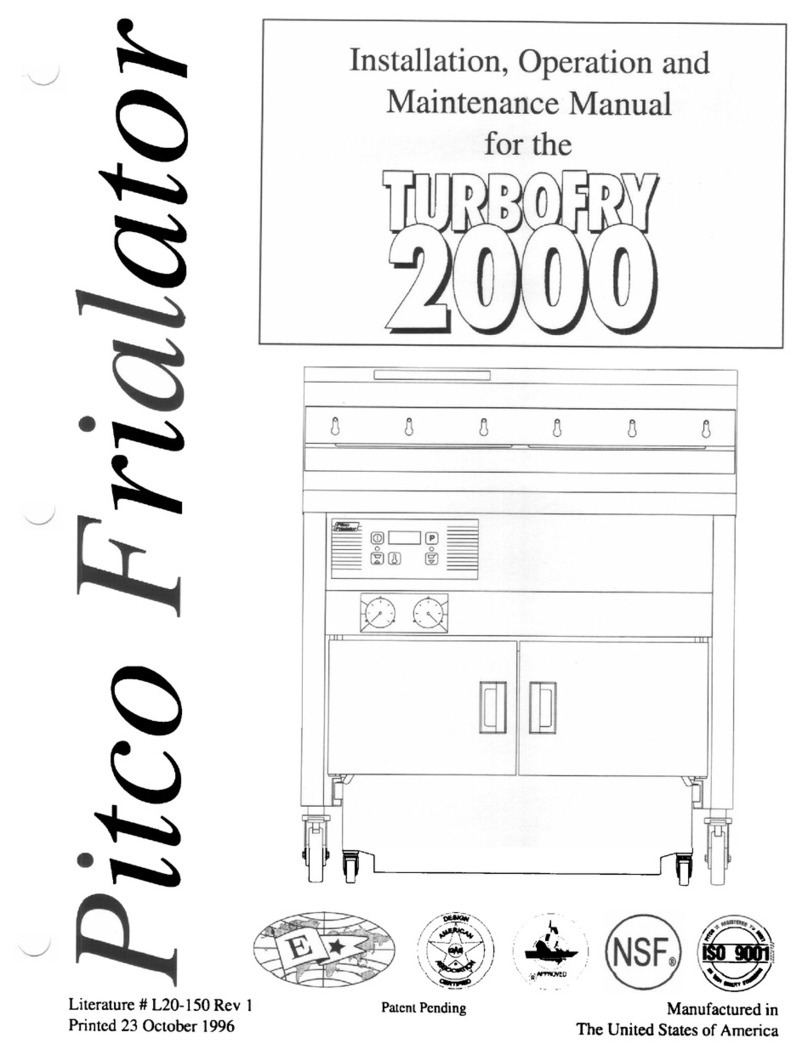

Chapter 1: General Information and Installation ..................................................................................... 1-1

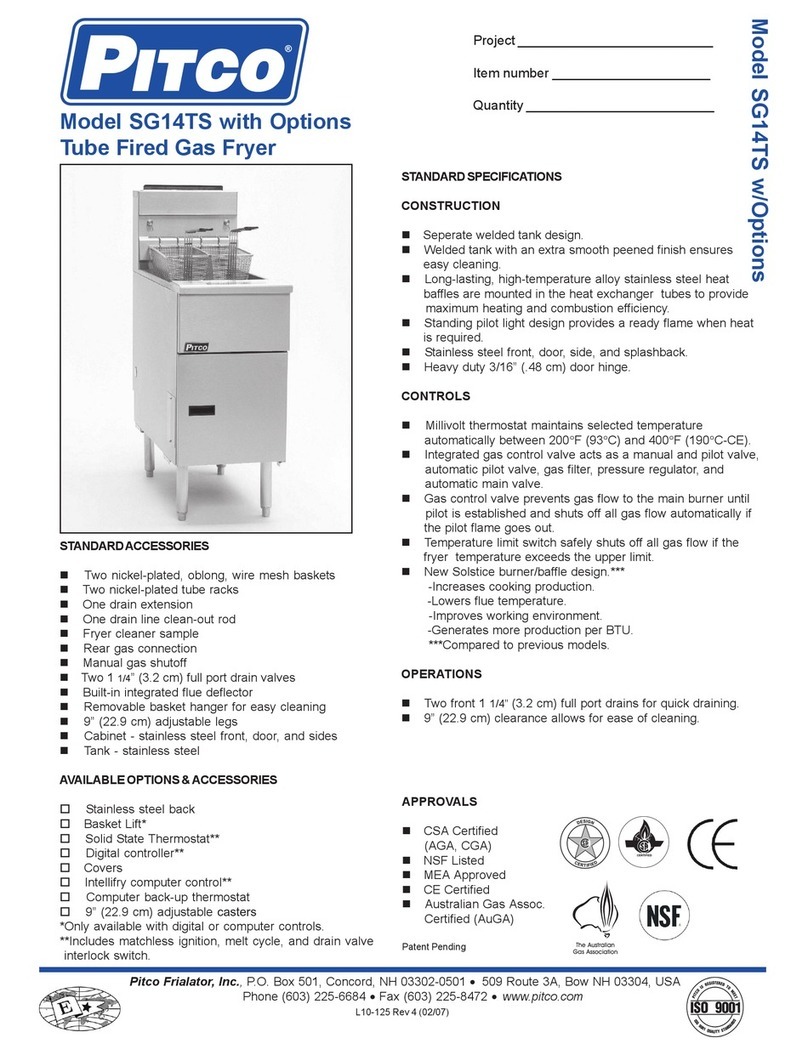

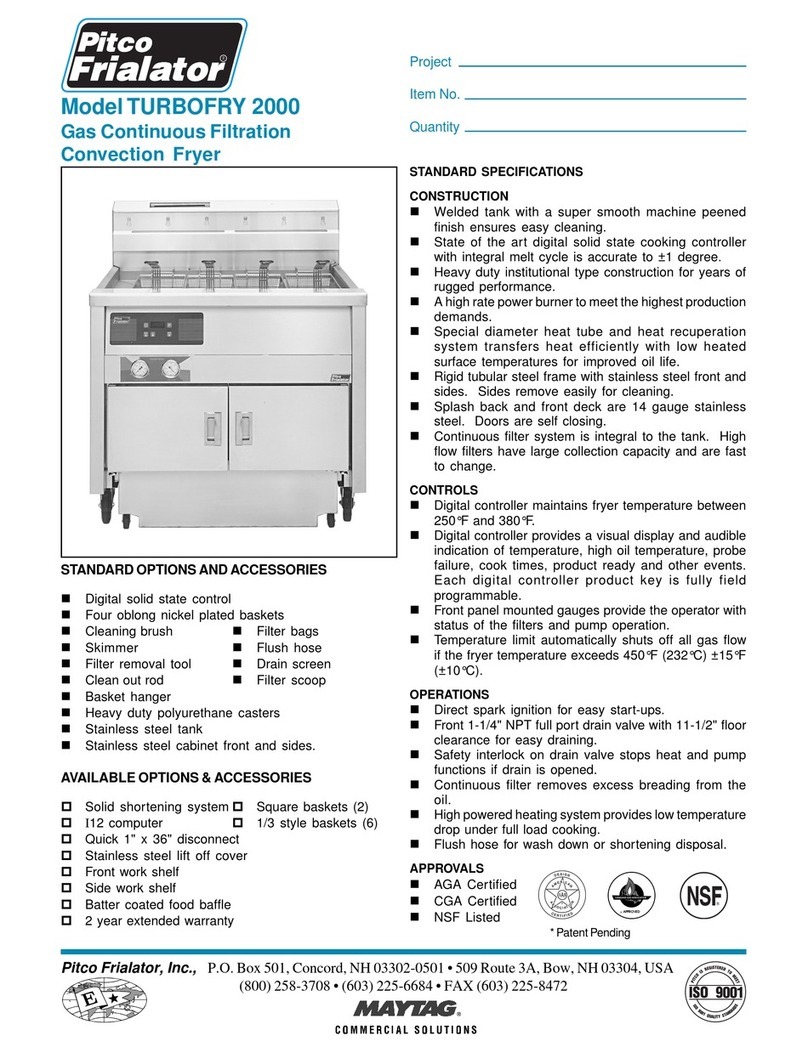

1.1 WHICH FRYER DO I HAVE? .................................................................................................. 1-1

1.2 CHECKING YOUR NEW FRYER............................................................................................ 1-1

1.2.1 Check Your Order ................................................................................................................ 1-2

1.3 ASSEMBLY AND LEVELING ................................................................................................. 1-2

1.3.1 Leg/Caster Installation and Adjustment ............................................................................... 1-2

1.3.2 Assembling Multi Fryer Systems ......................................................................................... 1-3

1.4 INSTALLATION ........................................................................................................................ 1-3

1.4.1 Installation Clearances.......................................................................................................... 1-3

1.4.2 Gas Connection .................................................................................................................... 1-3

1.4.2.1 Fuel Types ..................................................................................................................... 1-4

1.4.2.2 Gas Line Connection ..................................................................................................... 1-4

1.4.2.3 Quick Disconnect Gas Connection ................................................................................ 1-4

1.4.2.4 Fuel Supply Line Leak and Pressure Testing ................................................................ 1-5

1.4.3 Ventilation and Fire Safety Systems .................................................................................... 1-5

1.5 INITIAL ADJUSTMENTS ......................................................................................................... 1-5

1.5.1 Visual Checks ....................................................................................................................... 1-6

1.5.2 Burner Ignition Systems ....................................................................................................... 1-6

1.5.2.1 Pilot Flame Adjustment ................................................................................................. 1-7

1.5.3 Main Burner System ............................................................................................................. 1-8

1.5.3.1 Gas Line Requirements.................................................................................................. 1-8

1.5.3.2 Burner Adjustment ........................................................................................................ 1-8

1.5.4 Initial Cleaning ..................................................................................................................... 1-9

1.5.5 Thermostat Calibration Check ............................................................................................ 1-10

1.5.6 Thermostat Calibration ....................................................................................................... 1-11

Chapter 2: Operating Instructions ............................................................................................................. 2-1

2.1 FILLING THE FRYER ............................................................................................................... 2-1

2.1.1 Filling the Fryer With Liquid Shortening ............................................................................. 2-1

2.1.2 Filling the Fryer With Solid Shortening ............................................................................... 2-1

2.2 OPERATING INSTRUCTIONS ................................................................................................ 2-2

2.2.1 Fryer Start-Up ....................................................................................................................... 2-2

2.2.2 Melting Solid Shortening ...................................................................................................... 2-2

2.2.3 Fryer Shutdown .................................................................................................................... 2-3

2.3 DAILY CLEANING ................................................................................................................... 2-3

Chapter 3: Owner Maintenance and Adjustments ................................................................................... 3-1

3.1 WEEKLY FRYER CLEANING (BOIL OUT) .......................................................................... 3-1

3.2 FLUE INSPECTION .................................................................................................................. 3-1

3.3 TROUBLESHOOTING .............................................................................................................. 3-2

ENGLISH