UKlGINAL EQUll'~.l. LlMllr:.U nA1Uf..Af"C. I-. UADVI'ft.I ..,.,.,

GeDenlWarnDty

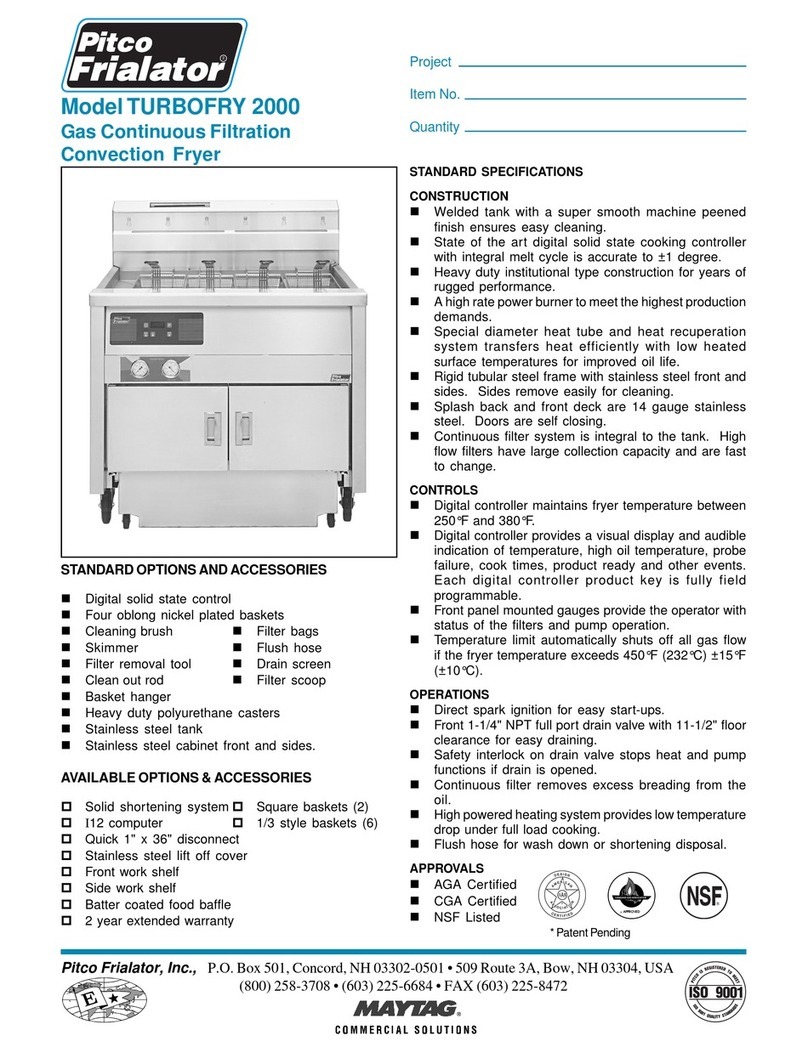

Pitco FriaI.-or. Inc. wmants to the 00IiD81 user of its 'n.rbGIry 2000 cookina appliauce tbI1l8id appliauce aIKi relaled equipment will ~~ fY.OJn

defa:ts in maIeriaIlJxi ~~ h1p uDder IDmaI UK fcr a penoo of (X1C (I) year from the dI&e of inltaD8Iicm. with ~ ckx:umcDt8tioo. subject

to the followin, alklitiODl, excepciom. exclusioos IJxi limiwjons.

What Is covered

This WlrTlnty is1imi1ed to the rer-ircrrepl-=ement at the Company's option. withoutcllmJe,ofany IJ8rt fwOO to be defective within the WlmDty

~oo aIxIreasonableexpeDleSincurrcd fcr freiaht IJximaterialfcr Ihcinstallatiooof such~ iD8kIitD. the~y's obliption shallbe1imi1edto

reimOOrsementfor nomaIlaln" on such parts.

Pitco Priala1or. Inc. IIreeI to pay the G.S.BlodgettCorporation Aulltorizcd ScrviccandPIrtSDisbibutor. for anylalxJrandmatcrial ~uired to

rer-ircrreplKe, at the Company's option, my IJ8rt which may fail duc todcfccu In mI1crial crwcx:k:mansbipdurina Ihc a\xJve ICDrZal warranty ~oo.

.'ry T~

In addition, the Company warrants to the original Uter of any fry tan~ II) I.: frtt from defects fcr a perioo of ten (10) years from the date of

man~. LatKx and freight shall be the reIponIibility of Ihc Uscf. Thl.. ~hall (1f\1~ohll~Dtc Ihc Company to repair or replace. at its option. any fry tank

which it deIamiDCS to be def~tive. Claims uDder Ibis item shall bc su~.,cd ~ a ..toIICrocnt dctailm, the defect, aIMi the ~ may IaIuR the rcturn

of the fry lank claimed to be defective. COIDputer or Di~ltal CCMaklaa ControDer

In addition. the ConIP8Dy warrants to the original user of any CookIng Computcr (11"DIgital ContlOl1« to be free from defects fcr a perioo of two (2)

yeIrIJrom the dateofmanuf~. Durina the two (2) yearpcriod all Chargcs involvcd In thc repl.:aDell8 0( a PitcoCompua cr DiIiIalCoallOUa' will

be the responsibility of Pitco Frialator Inc.

Bow to Keep Your Warranty In FoRe

. Make surc my shiwing damlgCl are reponed immediately. Damages of this nature are the responsibility of the carria.

. Install the unit popcriy. This is the reIpoDSlbility of the installcr and thc J"'tJCcdures are outliJIed in the manual. ~ rxx iDItaI1 it in a June

orresidence.

. Maintain theunit ~Iy. This is theresponsibilityof theuser.1hcpnxedurcs arcoudincdin themanual.

What . NOT covel8i uader this Wamaty

. AdjUlUlx:Dtl. stx:b &I caliInIXm,levelina. tightening of futenen cr plumbing cr el«-trical connections ncxma1ly USCJcialcd with initial

installationarenotcov~ uDderthis wlrTlnty. Theseproccdurcsareoodinedin theinstal1a1ionmanual.

. Damaged due to nO<xi, fire cr otha acts of Nature arc not covered under this WUT8nty.

. If theunit isuIcd fcr apIrpaIe otIu thanfcr whichit wasinlelml or dcsi&Dcd,resultiDsdamagcsarerxx cov~ uDderthewarranty.

. Failurcsduetoerraticvol. cr gassuppliesarenotcovaai uDderthewarranty.

. Material alterations cr modifications from the condition in which the unit left the factcry are not cov~ uDder the WunDty.

. Units with ~ oblila"lfal cr I'CIMVcdserialnumberrating platesarenotcovercdby the warranty.

. Any p8rtSoda' thanGenui~OEM p8rtI frm1 Pib>FriaJaIa".Inc. crits Authlx'izai PIns IIKi ServiceDisbi~tcrI arerxxCOYcn=dby the

WarTanty .

. Any other failure which is not attributable to a def~t in materials or workmanship is not cov~ tM the Warranty.

This WlrTlDty specifically excludes J*U which wear cr would be replaced under D(Xma\ UIIIe. includiD&. but not 1imi1ed to. electric lamps, fuses.

iDtCIU cr exterior finiIIIeIlJxi laskets,

Limi8atotileWarraaty

Outside the Uniled States of America and Canada, this WlrraDty is limiled to the replacement of parts and Pitco Prialator.lnc. will not bear any other

expense be it labor. miicqe. freight cr U'avel.

0IaJIeI fcr miJeaIC ova ~ buIMtIaI (100)miles,travel~ ova two (2)lOIn. overti~ andholidaych8rIeI~ rxxCOYcn=dUIMIccthis ~.

ThesechargesaretheIalXJDsibility of theilMfiyiduaJor finD rQIueIbnl theIe savi~.

If anyoral IWCIDentshavebeenmadereaanlinathe1PPIi&Jl(:C,theseItatcDlCfttsdonotconstitutewlrTlnties andarenotIJ8rtof thecontrlct of sale.

This limitrAi warrantyC(XIItituteIthecompIdc. rmalllKi exclusive~ with Iq81I to WiI.iDtD.

TInS UMn'ED WARRANTY IS EXCLUSIVE AND IS IN UEU OF Au.. OTHER WARRANTIES WBE11{ER WRm'EN. ORAL OR IM-

PLIED. INCLUDING. BUT N<YI'LIMITED TO ANY WARRANTY OF MERCHANTABILrrY ORPn"NP.SS~R A PAR11CULAR PURPOSEOR

WARRANTY AGAINST LATENT DEFEcrS. u.itatiD.- ~ I..I8.-aJ

In the event of a wunnty cr otIuclaim, the sole oblilation ofPitco Frialator.lnc. wiD be therer-ircrrq»laccmaIt. at the ~y's option, of the

applianceorthecomponentP8I'lThis rer-ir orreplacementwill beattheexpenseof PitcoFrialator.Inc.exceptaslimiled bythis WunDty s~ Any

repair cr replacemcntwxIer this WlrTlnty doesnot constitutem extensionin time to theoriginal WlrTlnty. PIrtI cov~ wwJerthis warranty will be

repairedcr repiKCd,at theCompany'soptjon. with - cr fWM:tiooalIyoperativeJ*U. TheliDIity 0( Pitco FriaIaUX'.Inc. 00 any claim of anykiIId.

including cllims hued 00 WarTanty.expess crimplied conIJ8ct, negligence.strict liability cr anyoda' lelal dIec.'ieI will beexclusively therer-ir cr

replacement of Ihc appliance. This liability will not include. and the purchaser specifically renounces any rilht to recover special. incidental. consequen-

tial orotIu damages of any kiIId. includiD&. but not 1imi1ed to. injuries to penonl, damage to~. 1011 of p'Ofits cr anticipatcd 100s of the UK of this

~Iiance-

If anyprovisiooof thiswunnty isunenforceablewxIerthelaw of anyjurisdiction. tbI1provisiononly will beinapplicablethere. and the rmlainder

of the warranty will remain unaffected. The maximwn exclusion or limitation allowedby law win besubstitutedfor Ihcunenforceableprovision.

a- to 0b88iII Wamaty Senice

First ~ ytKIrclaim to theG.S. BkJdgcu~ Autbori7al ServiceandPartsDistn~ clOKStto youJiving ~Icte m(Xjd. seriallJxi

code numbers.voltage,las type. anddescription of the problem. Proof of the datcof installation and/or the salesslip may aIIO be ~ If this

lXOCeIiuIeflils to beIatisfM:Iory,write theNational ServiccManager.PitcoPrialator.Inc.. P.O. Box SOl.COII(XXd.NH. 03302-0.501.USA

ORIGINAL

This warr8IIIy Jives you CCI1aiDIJ)ecifjc legal rights; you may have other ri&b&I

LIMITED WARRANTY- TURBOFRY 2000

11