Pitco PE14D User manual

Other Pitco Fryer manuals

Pitco

Pitco 14R Programming manual

Pitco

Pitco FBG18 User manual

Pitco

Pitco SSHLV Series User manual

Pitco

Pitco MG14S-C/MFD User manual

Pitco

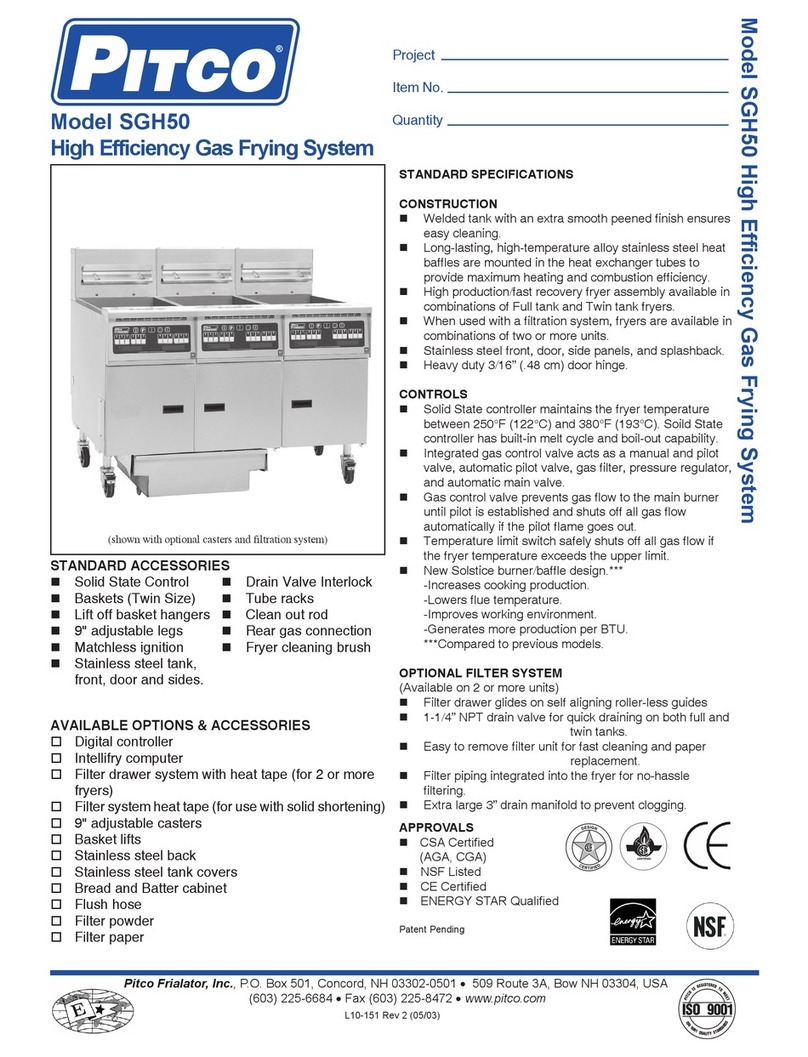

Pitco SGH50 User manual

Pitco

Pitco Frialator SG 14 User manual

Pitco

Pitco MGII User manual

Pitco

Pitco VF35 User manual

Pitco

Pitco SSHLV14 Series User manual

Pitco

Pitco Frialator SF14 UFM Guide