Pitco E7 User manual

Other Pitco Fryer manuals

Pitco

Pitco L20-281 User manual

Pitco

Pitco SE14 User manual

Pitco

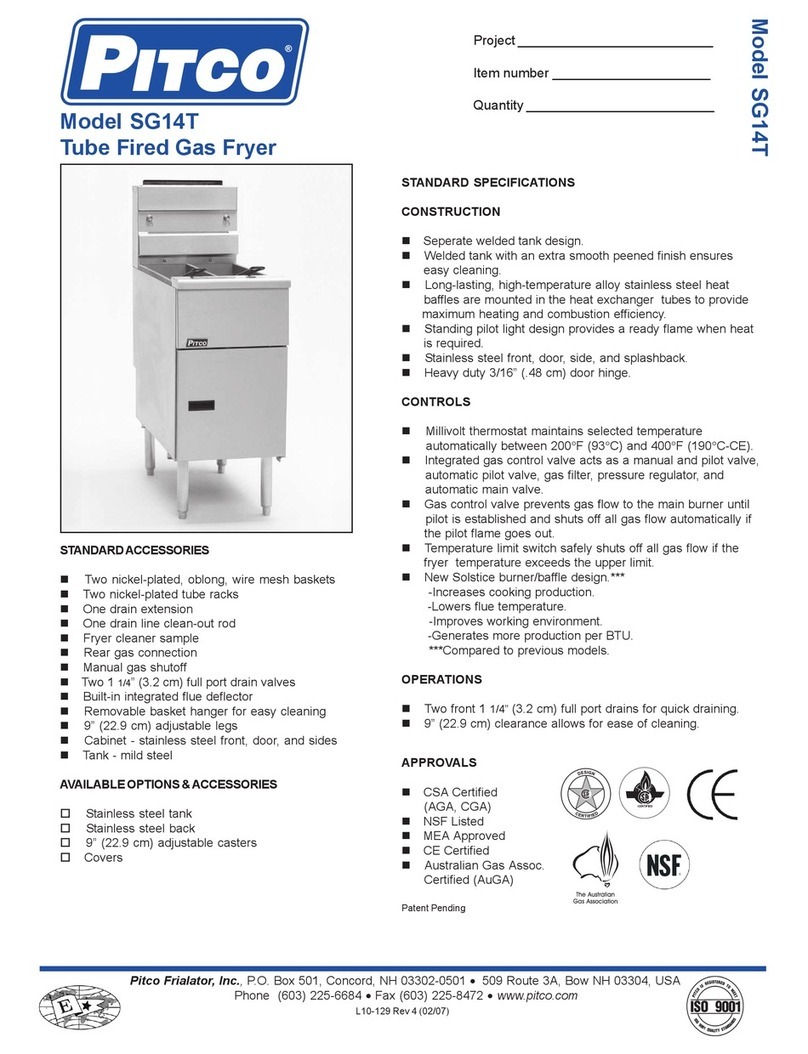

Pitco Frialator SG 14T User manual

Pitco

Pitco SSHLV184 Series User manual

Pitco

Pitco FBG18 User manual

Pitco

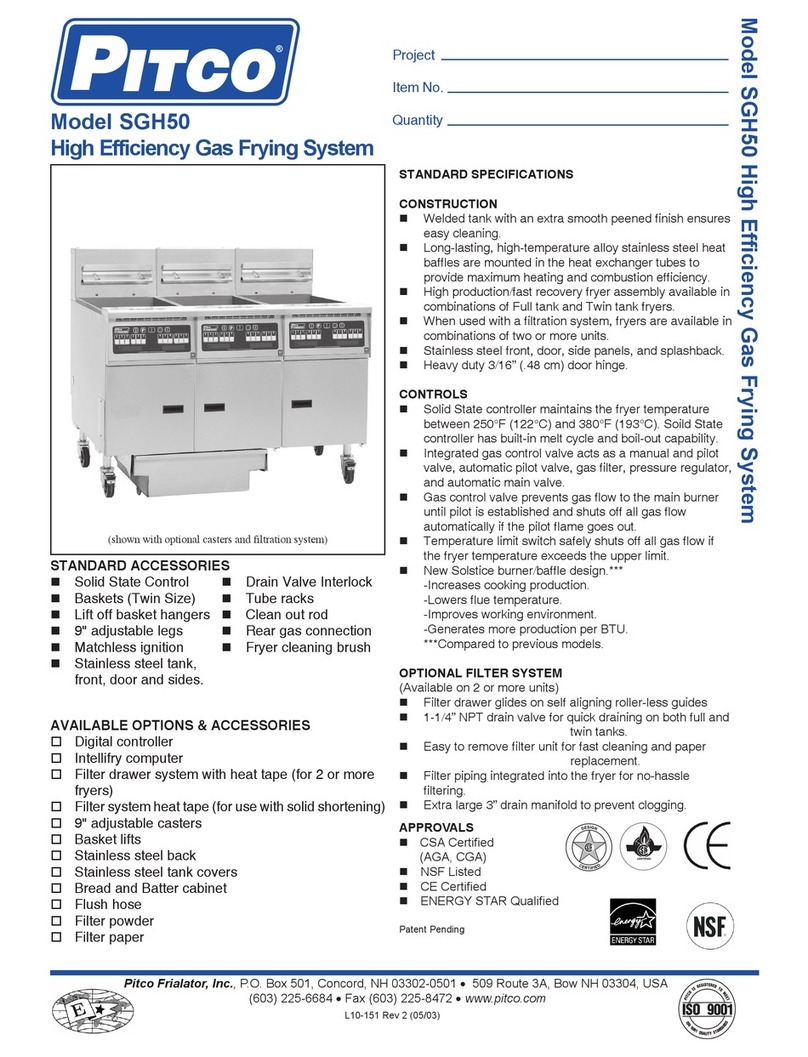

Pitco SGH50 User manual

Pitco

Pitco Frialator SG 14 User manual

Pitco

Pitco SE Series User manual

Pitco

Pitco Frialator SG 14 User manual

Pitco

Pitco SG18WKS User manual

Pitco

Pitco E7 Guide

Pitco

Pitco SELV14 User manual

Pitco

Pitco SGH50 Operating and installation instructions

Pitco

Pitco SEH50 User manual

Pitco

Pitco 14R Programming manual

Pitco

Pitco SG18S User manual

Pitco

Pitco TURBOFRY 2000 User manual

Pitco

Pitco SOLSTICE SFSSH55 User manual

Pitco

Pitco 20F User manual

Pitco

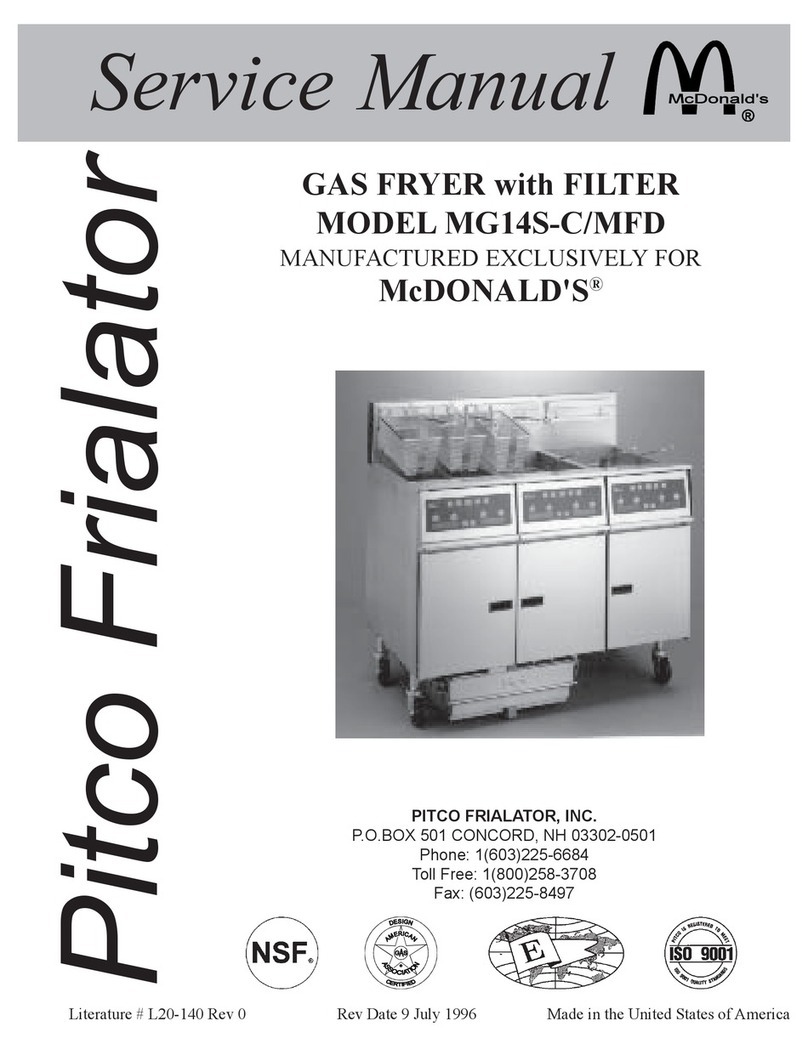

Pitco MG14S-C/MFD User manual