L22-236 Rev 0 (04/03) 4

Chapter 1: HOW DOES IT WORK?

The McDonalds Gas II fryer components function in

specific order of operation. Knowing and understanding

the sequence of fryer and components operation will

enable you to diagnose equipment failure more

accurately.

Heating System

Power to the machine is turned ON:

• If Fuse F1 on the Relay board is good, the A.C.

indicator will illuminate and the controller will be

supplied with 24 VAC and, if the drain valve handle

is closed, the proximity switch will supply 24 VAC

to the DVI (drain valve interlock) input at the

controller.

• The computer control is turned ON:

• The side on relay will be energized, closing the

circuit and the S.O. indicator on the Relay Board

will illuminate. If the hi limit is NOT tripped the

ignition module will receive 24VAC at terminal 6 (24

VAC).

• The ignition module will have a 24 VAC output from

terminal 3(PV) to the PV terminal on the gas valve

and the ignitor will spark. When the pilot has lit and

the module has proven the pilot flame, it will have a

24 VAC output at terminal 1(MV) and put 24 VAC

on pin #2 at connection J/P32 on the relay board.

The heat demand relay on the relay board will

interrupt the 24 VAC supply to the gas valve until

the controller calls for heat.

Note: When the controller is on, the pilot should

always remain lit.

• Controller calls for heat:

• The heat demand relay will energize supplying the

gas valve with 24 VAC and the H.D. indicator on

the Relay Board will illuminate. This will also supply

the computer with a heat feedback signal.

Hi Limit System:

• If the hi limit trips, it interupts the 24 VAC supply to

the ignition module. When the controller calls for

heat, it will not receive a 24 VAC heat feed back.

With approximately 90 seconds of heat feed back

loss, the controller will indicate an ignition failure or

heat failure.After the hi limit is reset (unit cools to

400°F + 20°F) the computer will have to be turned

off and back on for the unit to heat.

Hood Relay System: U.S./Canada units only

• There is one Hood Relay (K6) per "battery" of

fryers (located on rear bottom brace of left hand

fryer), it is wired in parallel to every computer

(both sides of a twin). When any side of any

computer is turned on this relay energizes

(turning on the hood) and will stay energized

until all of the computers are turned off.

Filter System:

• Opening the RED return valve handle will close

the proximity switch causing the "pump run" relay

to be energized. The pump motor will begin to

run.Closing the return valve handle will de-ener-

gize the relay and the pump motor will stop run-

ning.

• The pump system is equipped with a circuit breaker

which will de-energize the system and the heat tape

in the event of over current. The circuit breaker

switch must be in the ON position for the pump

and heat tape to operate.

• The return piping system may be equipped with

optional heat tape to prevent solidification of solid

shortening. The heat tape is low wattage and is on

constantly to maintain liquid shortening in the line.

Chapter 2: COMPONENT

TROUBLESHOOTING:

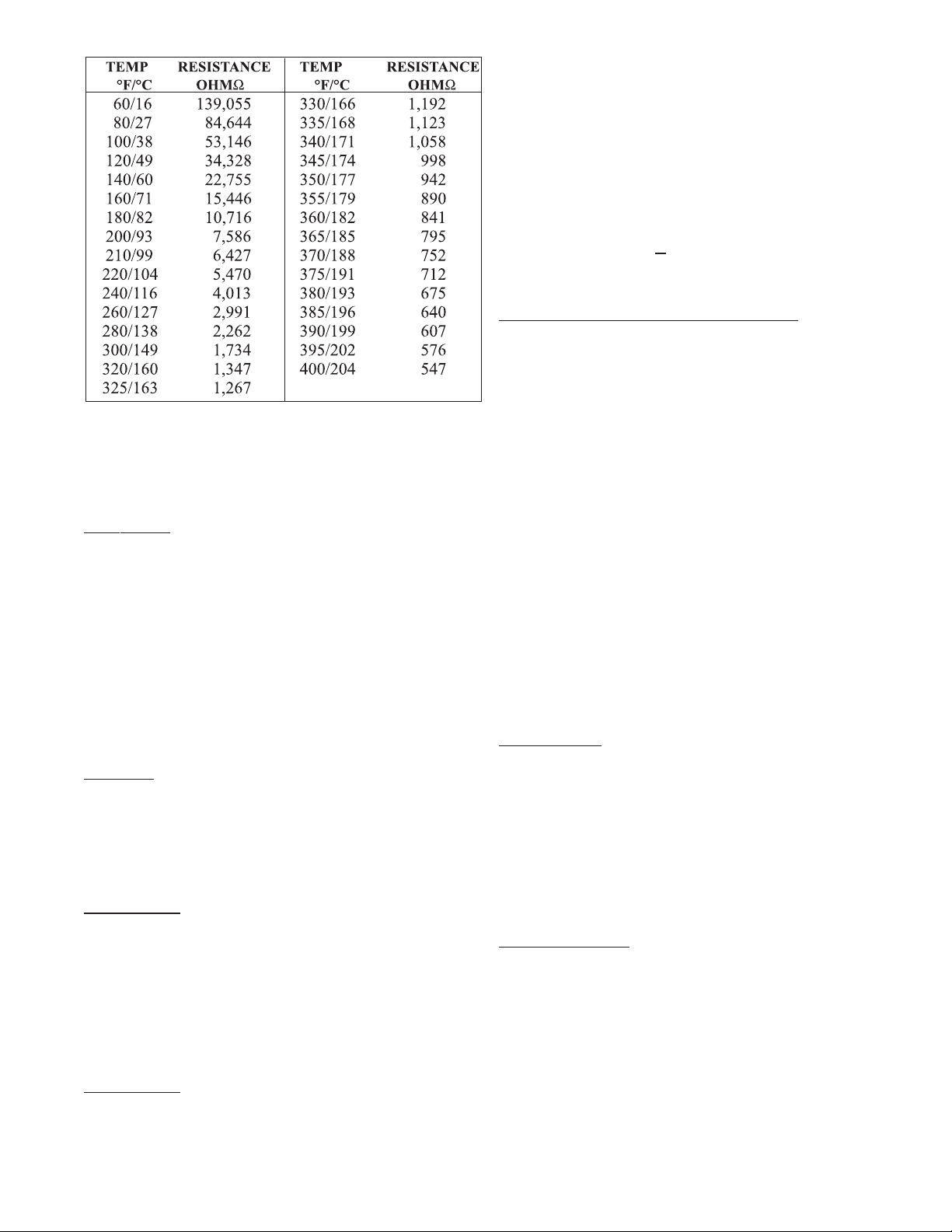

Probe:

The resistance of the probe will change as the tem-

perature changes. The resistance will decrease as the

temperature rises.

If the probe is suspect, check its resistance and the oil

temperature at which it was taken. Compare these

values on the probe resistance chart.

If the probe returns an open circuit or 0 Ohms read-

ing, it should be replaced. If the resistance varies more

than 30 Ohms when being checked between 325-

375°F the probe will give a false temperature reading

on the computer and should be calibrated (up to 10°F)

or replaced. However, it will continue to operate at a

slightly higher or lower temperature.

Allow the oil to cool and check the probe resistance