7

LIGHTING INSTRUCTIONS

a. Fill kettle before lighting.

b. Turn combination gas valve knob to “ON” position.

c. 1. Solid StateThermostat: Switch melt switch to desired position. Turn the Thermostat

knob to desired temperature. Turn the power switch to the "ON" position, the fryer is equipped

with a matchless ignition system and will automatically light the pilot, and heat up to set

temperature. (Note: if using solid shortening, set melt switch to the ON position)

2. Digital Controller: Press the button on the controller panel to turn fryer ON, the fryer is

equipped with a matchless ignition system and will automatically light the pilot, and heat up to

set temperature. (Note: if using solid shortening, ensure digital controller is programming is set

on the solid shortening melt cycle setting, by following digital programming instructions in

manual)

3. Computer Controller: Press the button on the controller panel to turn fryer ON, the fryer is

equipped with a matchless ignition system and will automatically light the pilot, and heat up to set

temperature. (Note: if using solid shortening, ensure computer controller is programming is set

on the solid shortening melt cycle setting, by following digital programming instructions in

manual)

WARNING

DONOTTURNCOMBINATIONGASVALVEKNOBTOTHE“ON”POSITIONUNTIL

VESSELISFULLOFWATERORSHORTENING. TURNINGTHEKNOBTO“ON”WITHVESSEL

EMPTYWILLDAMAGETHEVESSELORCOMPONENTSANDVOIDWARRANTY.

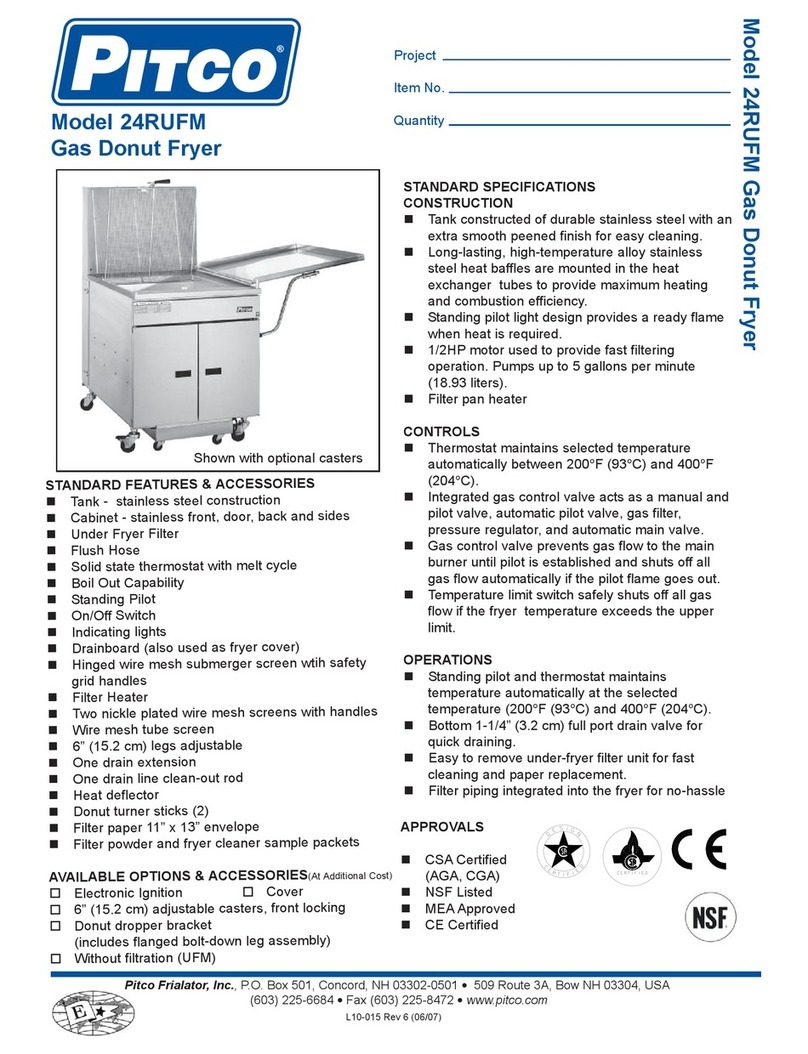

INITIALCLEANING

When the fryer is shipped, many of its parts are covered with a thin coat of oil for protection. Before the fryer is ready

forcookingitmustbecleaned. Thiswillremovetheoilcoatingandanyforeignmatterthatmayhaveaccumulatedduring

storage and shipment. Perform the cleaning as described below.

a. Fillthe tankwithwater andaddone packetofPitcofryer cleanerora milddetergent,and turngasvalve knob

to ON position.

VENTILATION AND FIRE SAFETY SYSTEMS

Your new fryer must have proper ventilation to function safely and properly. Exhaust gas temperatures can reach as

high as 1000°F (5380C). Therefore, it is very important to install a fire safety system. Your ventilation system should

bedesigned to allowforeasycleaning. Frequent cleaning oftheventilationsystem and thefryerwillreduce the chances

offire.

Excessive ventilation causes drafts, which will interfere with the proper operation of the pilot and the burner.

Leave at least 18 inches (45.72CM) of open space between the fryer's flue vent opening and the intake of the

exhaust hood. CAUTION

Ensurethatyourventilationsystemdoesnotcauseadowndraftatthefryer'sflueopening.

Downdraftswillnotallowthefryertoexhaustproperlyandwillcauseoverheatingwhich

maycausepermanentdamage. Damagecausedbydowndraftswillnotbecoveredunder

equipment warranty. NEVER allow anything to obstruct the flow of combustibles or

ventilation exiting from the fryer flue. DO NOT put anything on top of the flue area.

NOTICE

NEVER connect the blower directly to the flue openings. The direct flow of air will

cause poor temperature recovery, poor ignition, inefficient operation of the fryer, and

could extinguish the pilot.