15367-0-en-2.1.0

2017/12/26

Description: Interruptor de seguridad con actuador separado

additional protection systems must be provided (lock out/tag out) to mitigate risk.

Please contact technical assistance for more information (see SUPPORT paragraph).

6 INSTRUCTIONS FOR PROPER USE

6.1

Installation

-

Tighten the fixing screws of electrical conductors to a torque from 0.6 to 0.8 Nm.

-

Do not stress the device with bending and torsion.

-

Do not modify the device for any reason.

-

Do not exceed the tightening torques specified in the present manual.

-

The device carries out an operator protection function. Any inadequate installation

or tampering can cause serious injuries and even death, property damage, and

economic losses.

-

These devices must not be bypassed, removed, turned or disabled in any other way.

-

If the machine where the device is installed is used for a purpose other than that

specified, the device may not provide the operator with efficient protection.

-

The safety category of the system (according toEN ISO 13849-1), including the safe-

ty device, also depends on the external components connected to it and their type.

-

Before installation, make sure the device is not damaged in any part.

-

Avoid excessive bending of connection cables in order to prevent any short circuits

or power failures.

-

Do not paint or varnish the device.

-

Do not drill the device.

-

Do not use the device as a support or rest for other structures, such as raceways,

sliding guides or similar.

-

Before commissioning, make sure that the entire machine (or system) complies with

all applicable standards and EMC directive requirements.

-

The fitting surface of the device must always be smooth and clean.

-

The documents necessary for a correct installation and maintenance are always

available in the following languages: English, French, German andItalian.

-

Should the installer be unable to fully understand the documents, the product must

not be installed and the necessary assistance may be requested (see paragraph

SUPPORT).

- When the device is installed on a mobile frame and the actuator is installed on a

mobile door, ensure that the device cannot be damaged by simultaneous opening of

the frame and the door.

-

Always attach the following instructions to the manual of the machine in which the

device is installed.

-

These operating instructions must be kept available for consultation at any time and

for the whole period of use of the device.

6.2

Do not use in the following environments

Attention: Do not use in environments where dust and dirt may in any way

penetrate the head and deposit there. Do not use in particular where metal dust,

concrete or chemicals are spread.

-

In environments where continual changes in temperature cause the formation of

condensation inside the device.

-

In environments where the application causes collisions, impacts or strong vibrations

to the device.

-

In environments containing explosive or inflammable gases or dusts.

-

In environments where ice can form on the device.

-

In environments containing strongly aggressive chemicals, where the products used

coming into contact with the device may impair its physical or functional integrity.

6.3

Mechanical stop

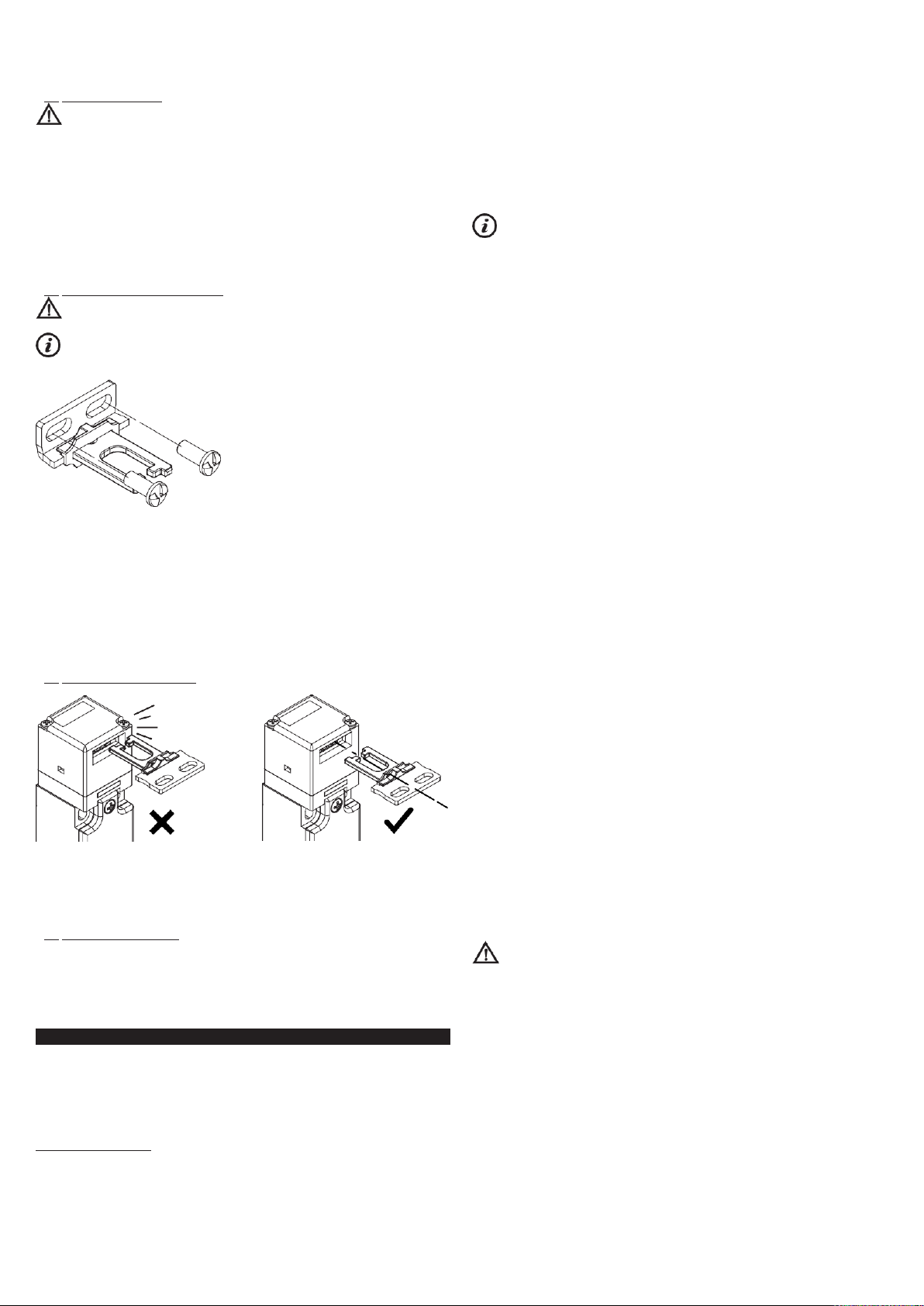

Attention: The door must always be provided with an independent end-limit

mechanical stop at limit of travel.

Do not use the device as mechanical stop for the door.

6.4

Maintenance and functional tests

Attention: Do not disassemble or try to repair the device. In case of any

malfunction or failure, replace the entire device.

Attention: In case of damages or wear it is necessary to change the whole

device including its actuator. Correct operation cannot be guaranteed when the device

is deformed or damaged.

-

The installer is responsible for establishing the sequence of functional tests towhich

the device is to be subjected before the machine is started up and during mainte-

nance intervals.

-

The sequence of the functional tests can vary depending on the machine complexity

and circuit diagram, therefore the functional test sequence detailed below is to be

considered as minimal and not exhaustive.

-

Perform the following sequence of checks before the machine is commissionedand

at least once a year (or after a prolonged shutdown):

1)

Open the guard while the machine is moving. The machine must stop imme-

diately. The stopping time of the machine must be always shorter than the time

required by the operator for opening the guard and reaching the dangerousparts.

2)

Try to start the machine while the guard is open. The machine must not start.

3)

Check correct actuator to device alignment. If the actuator inlet is worn, replace

the entire device and actuator assembly.

4)

All external parts must be undamaged.

5)

If the device is damaged, replace it completely.

6)

The actuator must be securely locked to the door; make sure that none of the

machine operator’s tools can be used to disconnect the actuator from the door.

7)

If you have difficulty inserting the actuator in the switch, never apply oil or grease

to the switch head; instead, check the actuator alignment as described in para-

graph INSTALLATION INSTRUCTIONS. If it is still difficult to insert the actuator,

replace the entire device.

8)

The device has been created for applications in dangerous environments, there-

fore it has a limited service life. Although still functioning, after 20 years from the

dateof manufacturethedevicemust bereplaced completely.The date of manufac-

ture is placed next to the product code (see paragraph MARKINGS).

6.5

Wiring

-

Keep the charge within the values specified in the electrical operation categories.

-

Only connect and disconnect the device when the power is off.

-

Always connect the protection fuse (or equivalent device) in series to the safety

electrical contacts.

-

At the end of the wiring, check that no contaminating element has been introduced

inside the device.

-

Before closing the device cover verify the correct positioning of the gaskets.

-

Verify that the electrical cables, wire-end sleeves, cable numbering systems and any

other parts do not obstruct thecover from closing correctly or if pressed between them

do not damage or compress internal parts.

-

During and after the installation do not pull the electrical cables connected to the

device. If traction is applied to the cables (not supported by an appropriate cable

gland) internal parts of the device may be damaged.

-

Adhere to the following minimum and maximum cross-sections of electrical

conductors designed for screw terminals:

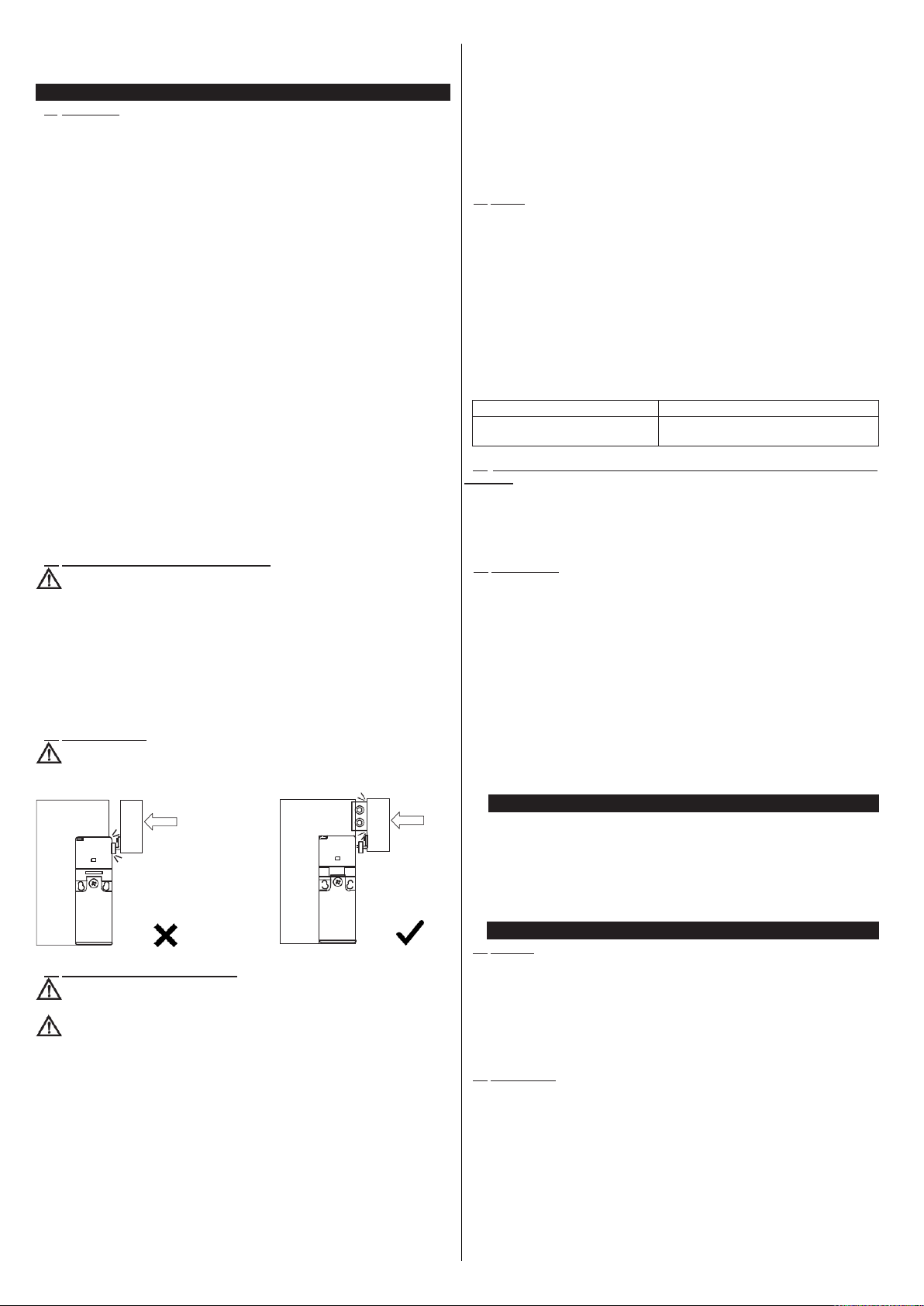

Contact blocks 20, 21, 22, 33, 34

Contact blocks 5, 6, 7, 9, 11, 13, 14, 18, 37, 66

min 1 x 0.34 mm2 (1 x AWG 22)

max. 2 x 1.5 mm2 (2 x AWG 16)

min 1 x 0.5 mm2 (1 x AWG 20)

max. 2 x 2.5 mm2 (2 x AWG 14)

6.6

Additional prescriptions for safety applications with operator protection

functions

Provided that all previous requirements for the devices are fulfilled, for installations with

operator protection function additional requirements must be observed.

-

The utilization implies knowledge of and compliance with following standards: EN

60947-5-3, EN ISO 13849-1, EN 62061, EN 60204-1, EN ISO 14119,

EN ISO 12100.

6.7

Limits of use

-

Use the device following the instructions, complying with its operation limits and the

standards in force.

-

The devices have specific application limits (min. and max. ambient temperature,

mechanical endurance, IP protection degree, etc.) These limitations are met by the

device only if considered individually and not as combined with each other.

-

The manufacturer’s liability is to be excluded in the following cases:

1)

Use not conforming to the intended purpose;

2)

Failure to adhere to these instructions or regulations in force;

3)

Fitting operations not carried out by qualified and authorized personnel;

4)

Omission of functional tests.

-

For the cases listed below, before proceeding with the installation contact our techni-

cal assistance service (see paragraph SUPPORT):

a)

In nuclear power stations, trains, airplanes, cars, incinerators, medical devices or

any application where the safety of two or more persons depend on the correct opera-

tion of the device;

b)

Applications not contemplated in this instruction manual.

7

MARKINGS

The outside of the device is provided with external marking positioned in a visible place.

Marking includes:

-

Producer trademark

-

Product code

-

Batch number and date of manufacture. Example: A18 FR1-123456. The batch's first

letter refers to the month of manufacture (A=January, B=February, etc.). The second

and third letters refer to the year of manufacture (18 = 2018, 19 = 2019, etc…).

8

TECHNICAL DATA

8.1

Housing

housing made of glass fibre reinforced technopolymer, self-extinguishing, shock-proof

and with double insulation

FR series: one threaded conduit entry M20x1.5 (standard)

FK series: one threaded conduit entry M16x1.5 (standard)

FX series: two knock-out threaded conduit entries M20x1.5 (standard)

FW series: three knock-out threaded conduit entries M20x1.5 (standard)

Protection degree: IP67 acc. to EN 60529 with cable gland of equal or higher

protection degree.

8.2

General data

SIL (SIL CL): up to SIL 3 acc. to EN 62061

Performance Level (PL): Up to PL e acc. to EN ISO 13849-1

Mechanical interlock, coded: type 2 acc. to EN ISO 14119

Coding level: low acc. to EN ISO 14119

B10d safety parameters: 2,000,000 for NC contacts

Mission time: 20 years

Ambient temperature: -25°C … +80°C

Storage temperature: -40°C … +80°C

Max.actuation frequency: 3600 operating cycles/hour

Mechanical endurance: 1 million operating cycles

Max.actuation speed: 0.5 m/s

Min. actuation speed: 1 mm/s

Mounting position: any

Actuator extraction force: 10 N (standard), 30 N (-E3 versions)