2) CALIBRATION PROCEDURE (THE EASY PART)

As trimpots on VCOs go out of adjustment over time, so do the trimpots on the power supplies that run them. Therefore it’s best to cal

your VCOs while powered by the PSU they will connected to in the system. This assures they are calibrated to the same supply voltage

they will see in their working environment. Before you do this:

1) Make sure you are powering your Model 15’s with the same power supply they will be powered from once remounted in your

synthesizer

2) Make sure the VCOs you are calibrating are on for at least ten minutes before you perform these tests.

3) Perform these tests in a comfortable room-temperature environment with little to no air flow (don’t attempt to cal a

synth module with an air conditioner, heater or fan blowing in over them.

A) FIRST CALIBRATION: 1 VOLT PER OCTAVE TRACKING ADUSTMENT

A1) Connect a 1v/oct standard CV into the 1v/OCT input of your Model 15. For best calibration, this should come from the output of a

midi to CV converter because you’re going to need a reference signal (that form either a midi or VA instrument) to set up the 1V/Oct

tracking.

A2) Make a patch by which you can simultaneously hear the output of your VCO and that of preferably either a VA softsynth or some

Type of digital instrument - something you know is in calibration. (there’s no use calibrating to a false reference). Configure this ref.

to a RAMPWAVE which BYPASSES ANY FILTERING, EFFECTS or PROCESSING. A RAW WAVEFORM IS REQUIRED.

A3) With your Model 15 sounding continuously in the speakers, play and hold a C1 on your midi keyboard. While sustaining that note,

tune your Model 15 so that it is in tune with the pitch coming from your reference (digital) instrument. This is probably the most critical

part of this test. Take your time, tune carefully for the minimum amount of phasing.

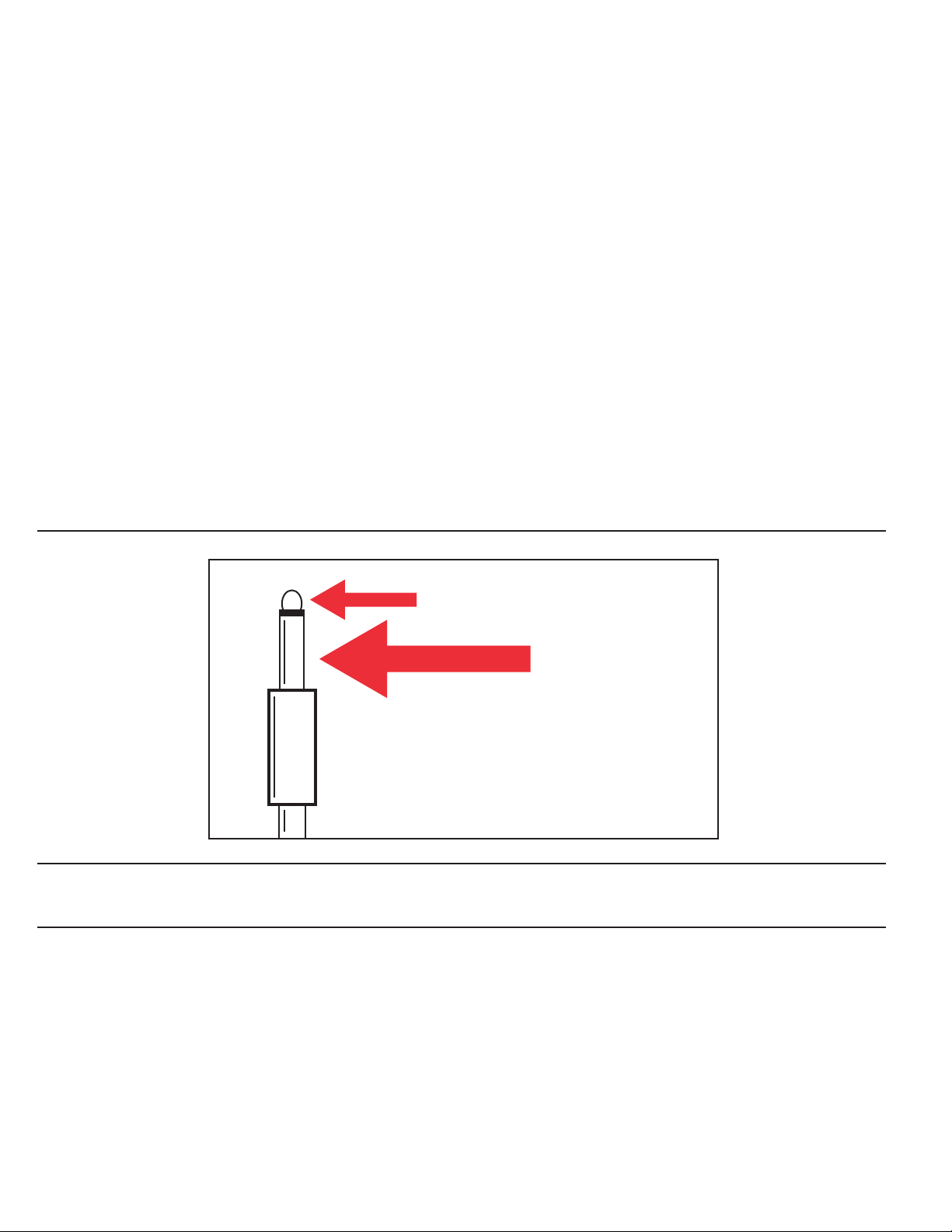

A4) Play and hold a C4 on your midi keyboard. Using a plastic pot tweeker tool (see diagram 3), turn the 1 volt/octave trim pot (labeled

A in diagrams 2A and 2B) until the pitch form your M15 and your digital reference tone are tuned.

A5) Once they are in tune, play notes in-between C1 and C4 to verify tracking. If they don’t, then repeats steps A2 and A4 until they do.

A6) Now play and hold a C5 on your reference instrument and repeat the trim pot tuning performed in A4. Once you’re there, repeat the

process with a C6, C7, etc...until you’ve reached the maximum usable calibrated range the Model 15.

A7) If you a adjusting more than one Model 15, repeat steps A2 through A6 - but replace your digital reference with a Model 15 you

have already adjusted. You need to make sure your VCOs are tracking with each other. This is why their power is daisy-chained with a

single power cable and why you need to calibrate them all while running off the same PSU each will be while mounted in your synthesizer.

So go down the line of every Model 15 you’re adjusting, and use the previous one as the reference tone for the next, down the line until

they are all tracking not only to 1v/octave...but to each other.