5

Table of Contents

Chapter 1: Getting Started 6

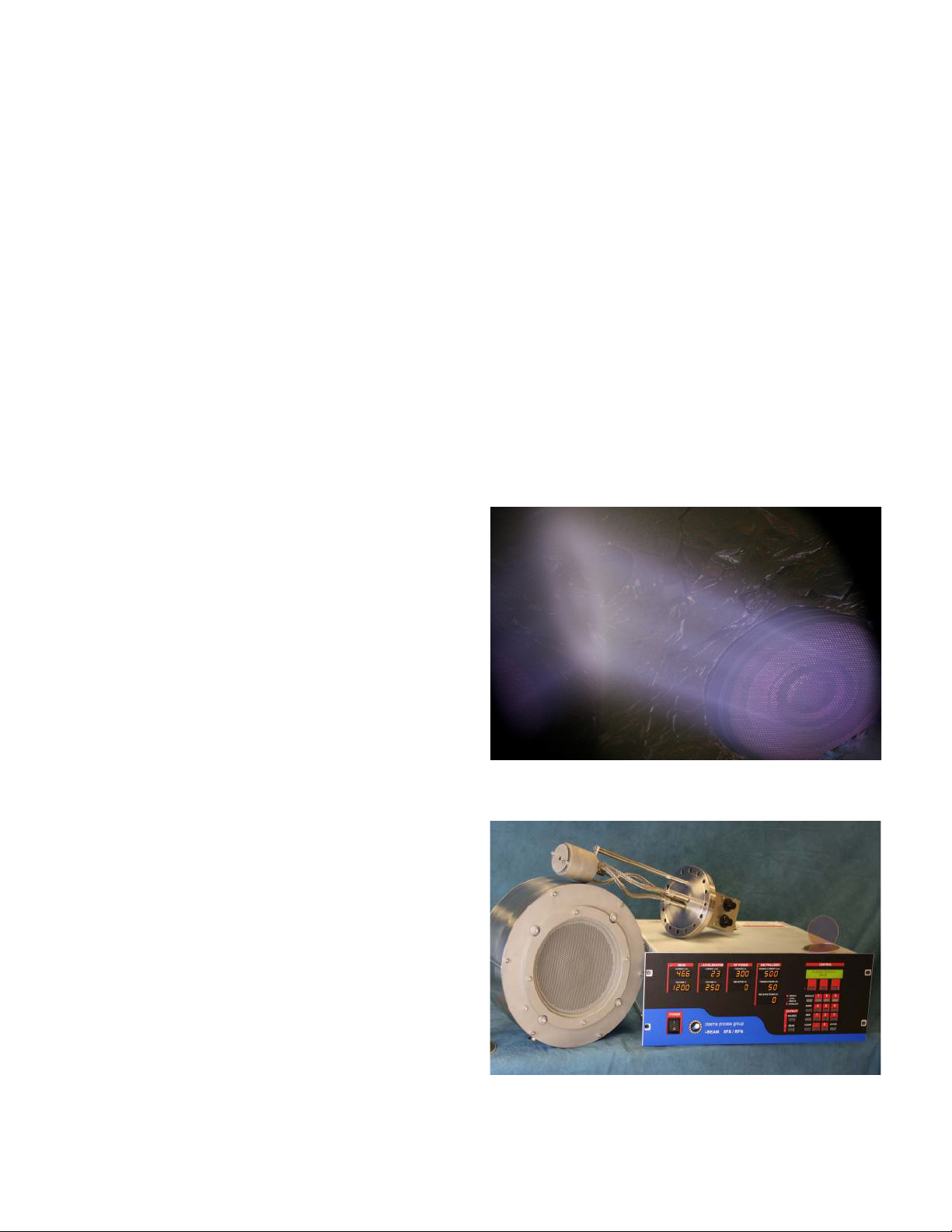

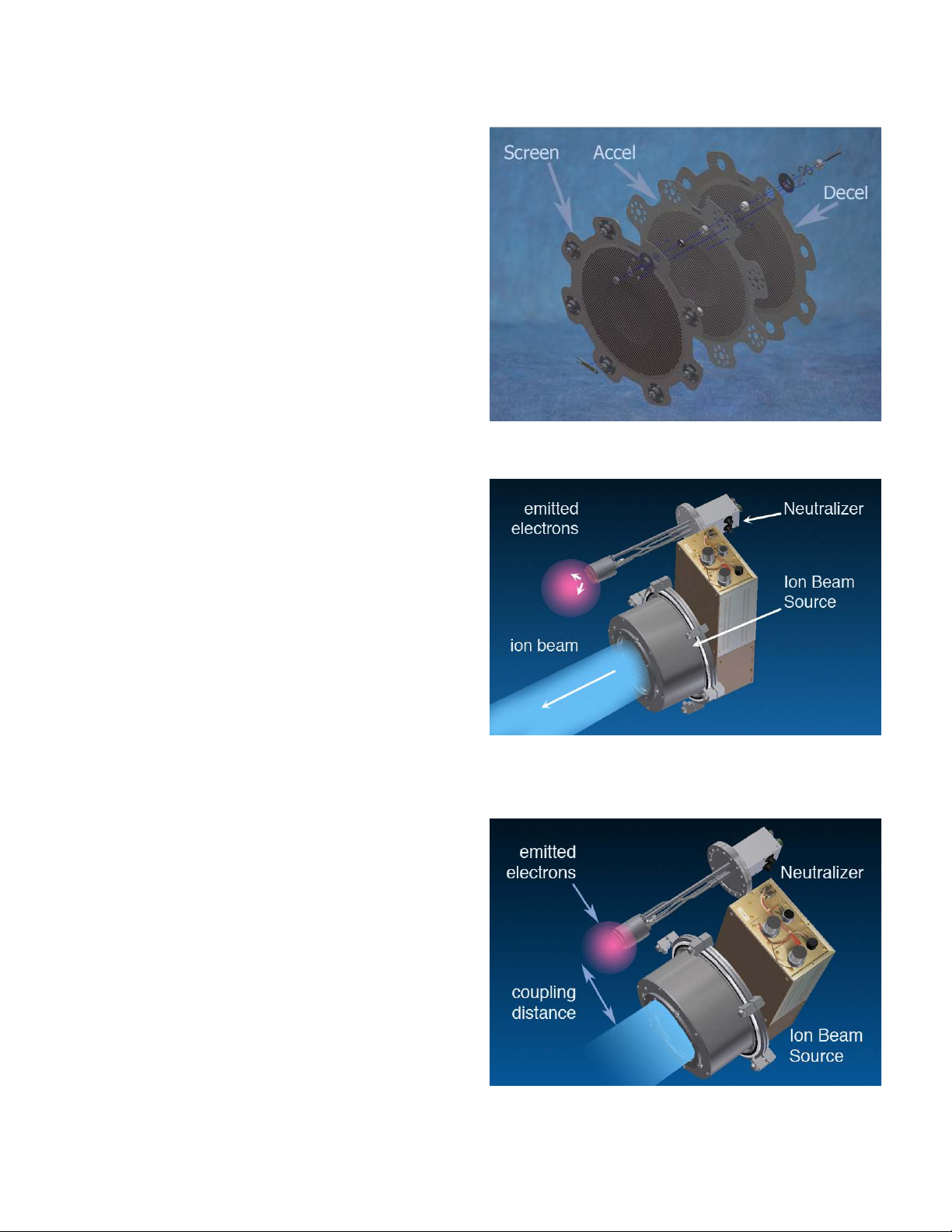

Section 1.1: Terminology 6

Section 1.2: Overview 8

Chapter 2: Installation 11

Section 2.1: General Requirements 11

Section 2.2: Layout 12

Section 2.3: Unpacking 13

Section 2.4: Source Installation 14

Chapter 3: Specications 18

Section 3.1: Specications for RF Neutralizer (RFN) 18

Section 3.2: Specications for 6 cm RF 19

Section 3.3: Specications for 12 cm RF 20

Section 3.4: Specications for 16 cm RF 21

Section 3.5: Specications for 23 cm RF 22

Section 3.6: Specications for Linear RF 23

Section 3.7: Power Supply Specications 24

Chapter 4: Operation 25

Section 4.1: Quick Start Sequence 25

Section 4.2: Additional Resources 29

Chapter 5: Advanced Operation 30

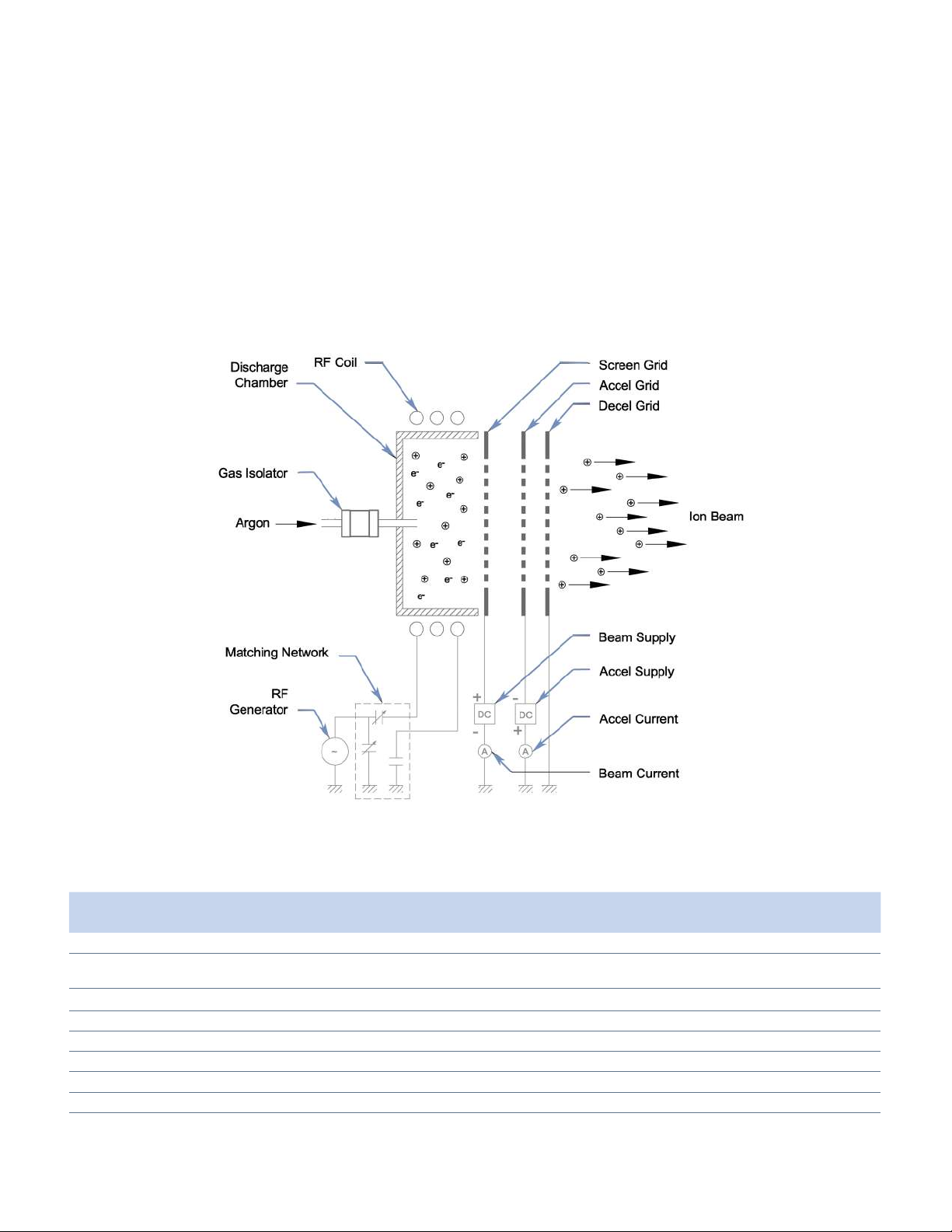

Section 5.1: Grid Theory 30

Section 5.2: Source Ignition 36

Section 5.3: Source Ignition Sequence 38

Section 5.4: Technical Tips 39

Chapter 6: Maintenance 42

Section 6.1: Maintenance Work Station 42

Section 6.2: Schedule 43

Section 6.3: Common Wear and Tear 44

Section 6.4: Recommended Spare Parts 45

Chapter 7: Troubleshooting 46

Section 7.1: Common Issues and Quick Fixes 47

Section 7.2: Power Supply Error Codes 48

Section 7.3: RF Neutralizer (RFN) Errors 51

Section 7.4: Starting the Source 53

Section 7.5: Turning on the Beam 54

Section 7.6: Additional Resources 55

Chapter 8: Parts and Drawings 56

Section 8.1: Navigating Grid Assembly Drawings 56

Section 8.2: Part Numbers for RFN 57

Section 8.3: Part Numbers for 6 cm RF Source 58

Section 8.4: Part Numbers for 12 cm RF Source 61

Section 8.5: Part Numbers for 16 cm RF Source 64

Section 8.6: Part Numbers for 23 cm RF Source 69

Section 8.7: Part Numbers for 6x22 cm RF Source 72

Section 8.8: Part Numbers for 6x30 cm RF Source 73

Appendix A: Cleaning Guide 75

Section A.1: Molybdenum Grid Cleaning Procedure 75

Section A.2: Reassemble 78

Section A.3: Electrical Testing 82