Pneumax PTO-Driven Compressor Kit Installation Guide

Page 2of 36

Table of Contents

Installation Overview.........................................................................................................................4

Power take-off suggestions ...............................................................................................................5

PTO installation.................................................................................................................................6

Air compressor installation.................................................................................................................7

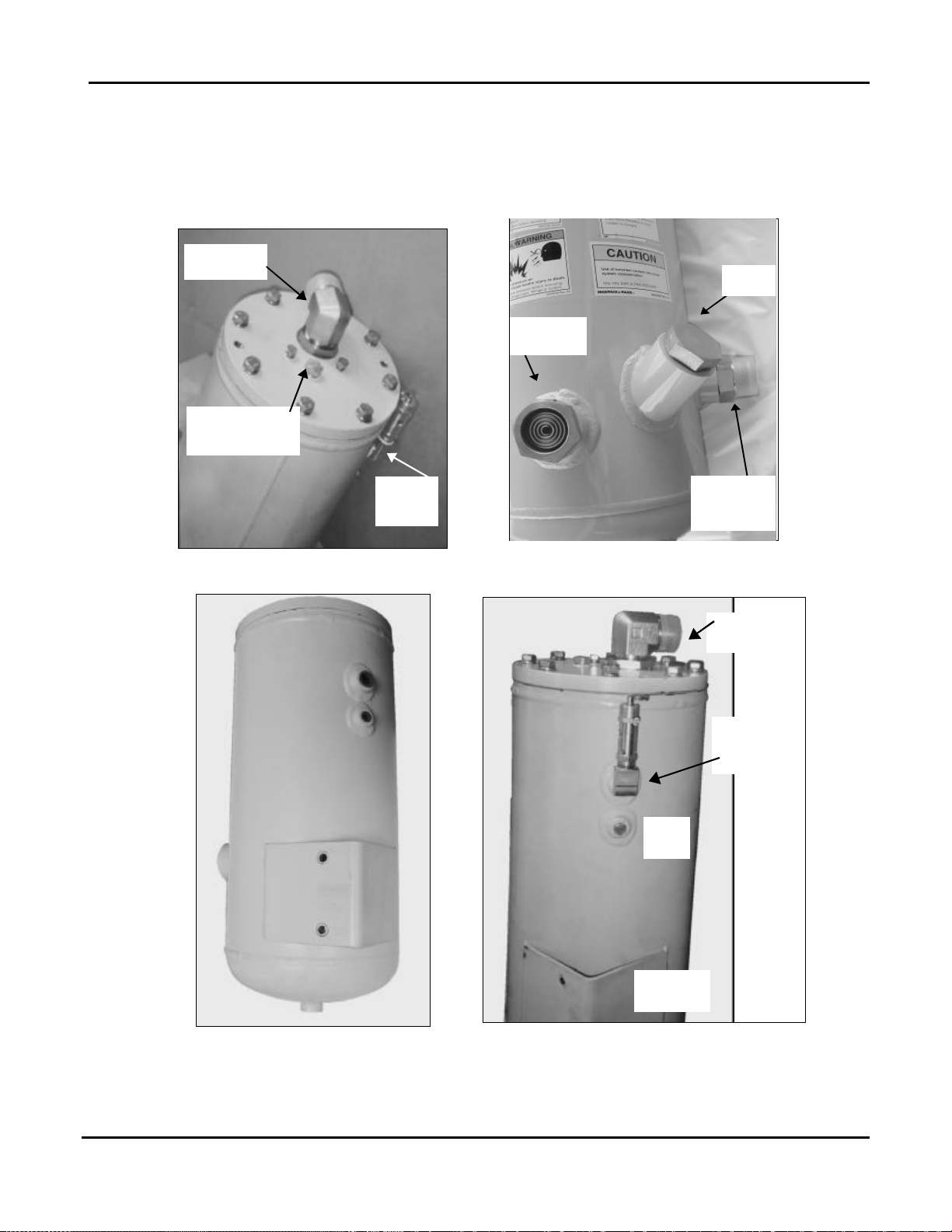

Air-oil sump installation......................................................................................................................8

Oil Temperature Gauge (all sumps).................................................................................................11

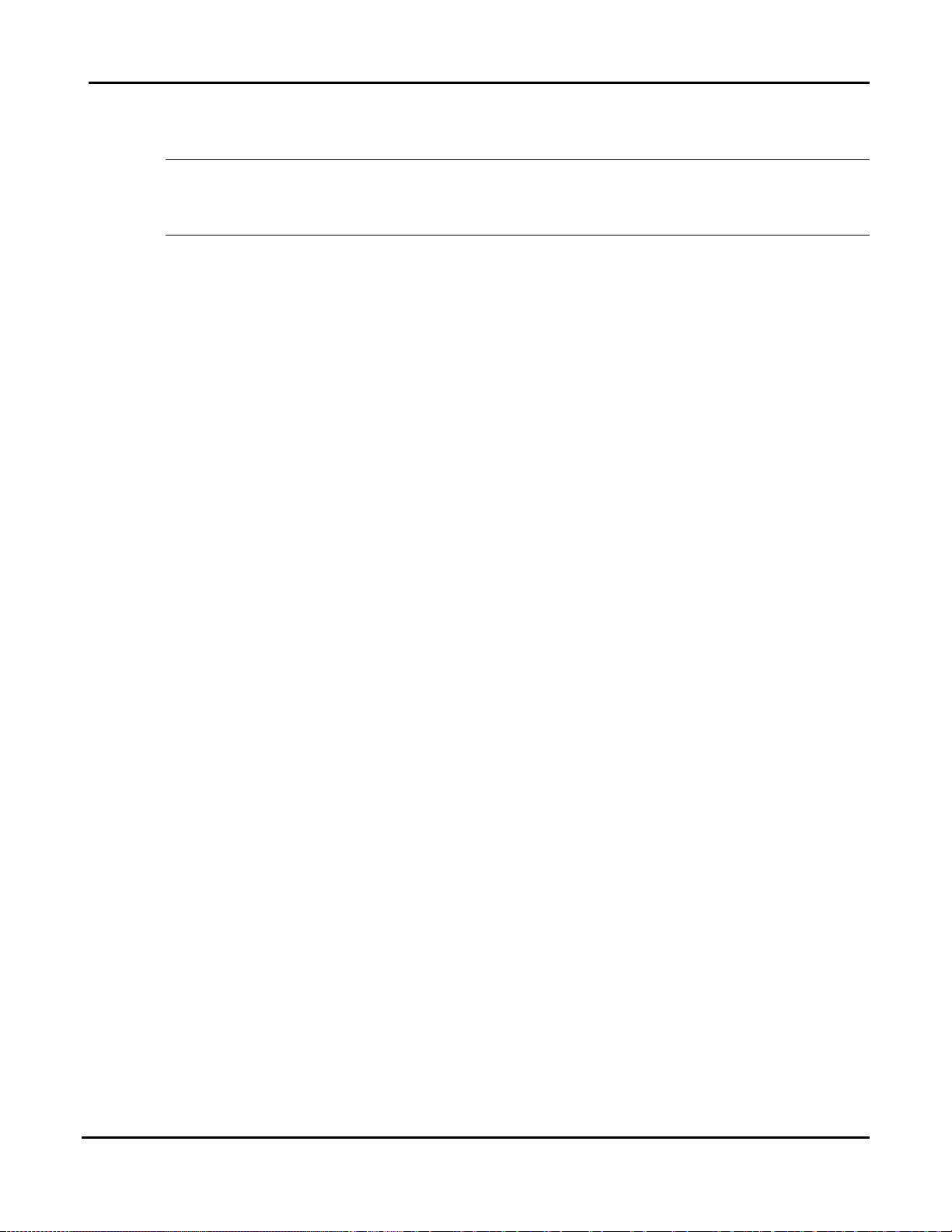

Separator/filter installation............................................................................................................... 12

Air Compressor Cooler and Hydraulic Filter Installation....................................................................13

Auto-Sync....................................................................................................................................... 15

1. UNLOAD Mode Adjustment.....................................................................................15

2. FIXED Mode Adjustment .........................................................................................16

3. AUTO Mode Adjustment..........................................................................................17

Suggested components for CAFS discharges:.................................................................................18

Discharge kits...............................................................................................................18

Air distribution manifold: ...............................................................................................18

Suggested air hose ......................................................................................................18

Air Pressure Gauge......................................................................................................18

Compressor System........................................................................................................................19

Schematics and Dimensional Drawings...........................................................................................23

Basic Compressed Air Foam System (CAFS) Schematic..............................................23

80-SP with 8-inch Vertical Sump, Hydraulic Schematic.................................................24

140/200-SP with 10-inch Vertical Sump, Hydraulic Schematic......................................25

80-SP Manual Auto-Sync Valves, Air and Water Connections.......................................26

140/200-SP Manual Auto-Sync Valves, Air and Water Connections..............................27

Compressor Installation Angles....................................................................................28

Eight-Inch Vertical Sump..............................................................................................29

Ten-Inch Vertical Sump................................................................................................30

80-P Heat Exchanger (Oil cooler).................................................................................31

140/200-SP Heat Exchanger (Oil Cooler) .....................................................................32

80-SP Separator Filter..................................................................................................33

140/200-SP Oil and Separator Filters ...........................................................................34

Balance Valve and Auto-Sync Controls, Panel Cutout...................................................35

Companion Flange.......................................................................................................36