Table of Contents

Preface ............................................................................................................................................................ 1

1INTRODUCTION ............................................................................................................................................. 1

1.1 Warranty and liability .......................................................................................................................... 1

1.1.1 Guarantee conditions ................................................................................................................ 1

1.1.2 Liability ...................................................................................................................................... 1

1.2 Safety .................................................................................................................................................. 2

1.2.1 Safety regulations...................................................................................................................... 2

1.2.2 Safety provisions and measures ............................................................................................... 2

1.2.3 Pictograms used ....................................................................................................................... 2

2. FOR THE INSTALLER ..................................................................................................................................... 3

2.1 ComfoAirconguration...................................................................................................................... 3

2.2 Technicalspecications ..................................................................................................................... 4

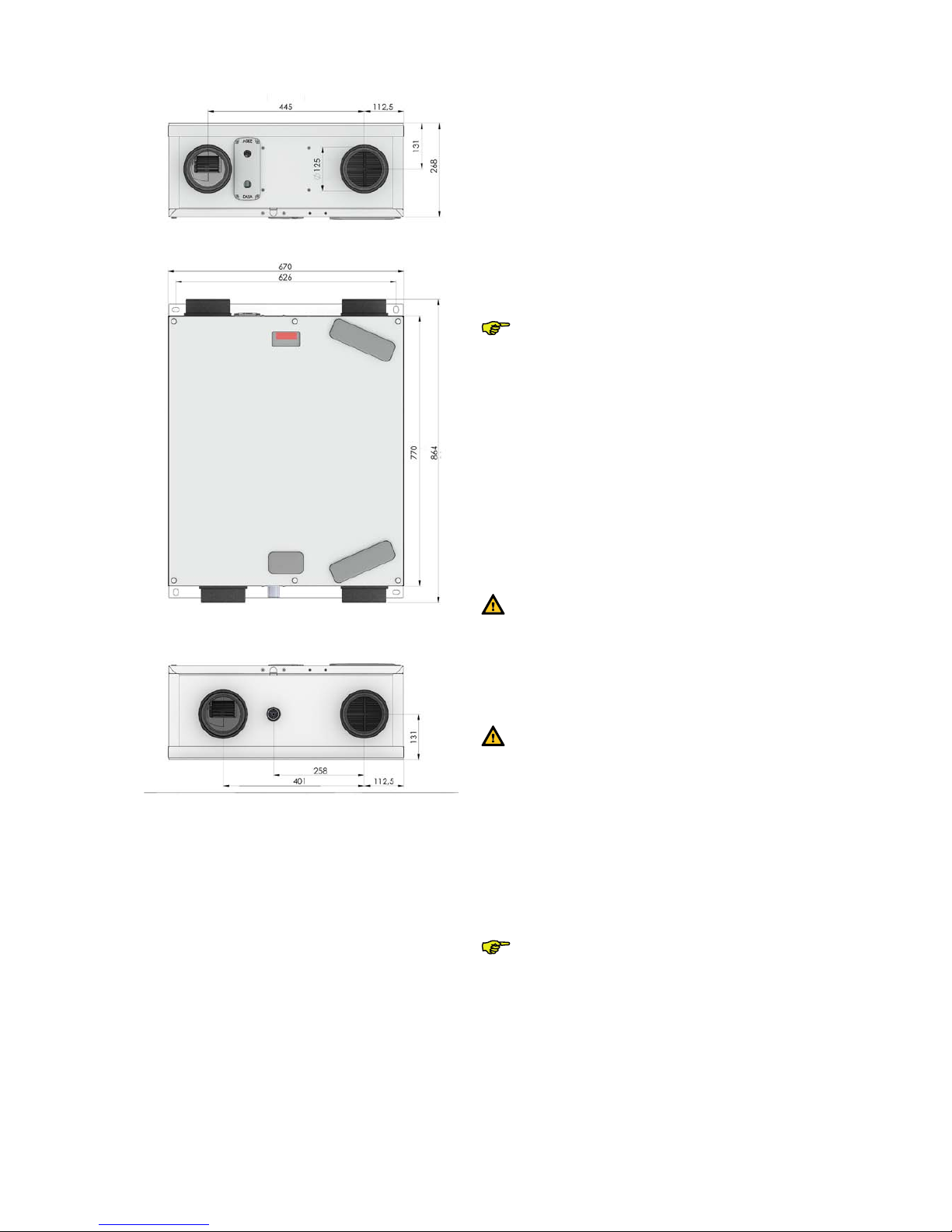

2.3 Dimension sketch ............................................................................................................................... 6

2.4 Installation conditions ........................................................................................................................ 6

2.5 Installation of the ComfoAir ............................................................................................................... 6

2.5.1 Transport and unpacking...........................................................................................................6

2.5.2 Checking the delivery ................................................................................................................ 6

2.5.3 Rework Right to Left version ..................................................................................................... 7

2.5.4 Connecting the power cord.......................................................................................................7

2.6 MountingoftheComfoAir.................................................................................................................. 7

2.6.1 Mounting on the ceiling ............................................................................................................ 7

2.6.2 Mounting on the wall ................................................................................................................. 8

2.6.3 Connection of the air ducts ....................................................................................................... 8

2.6.4 Connection of the condensation drain ......................................................................................9

2.7 CommissioningtheComfoAir............................................................................................................ 9

2.7.1 Display on the unit................................................................................................................... 10

2.7.2 CC Ease panel......................................................................................................................... 10

2.7.3 P menus for the user ............................................................................................................... 12

2.7.4 P menus for the installer.......................................................................................................... 14

2.8 Programmingairspecications ...................................................................................................... 17

2.9 Maintenance by the installer............................................................................................................ 18

2.9.1 Inspecting and cleaning the heat exchanger........................................................................... 18

2.9.2 Inspecting and cleaning the fans............................................................................................. 19

2.10 Malfunctions...................................................................................................................................... 19

2.10.1 Malfunction alerts on digital operating devices....................................................................... 19

2.10.2 3-position switches with malfunction indicator.......................................................................19

2.10.3 What to do in the event of a malfunction / Trouble shooting .................................................. 20

2.10.4 Malfunctions (or problems) without alerts .............................................................................. 26

2.11 Service parts...................................................................................................................................... 27

2.12 Wiringdiagram:ComfoAir160........................................................................................................ 28

2.13 EEC declaration of conformity ........................................................................................................ 29

III - EN