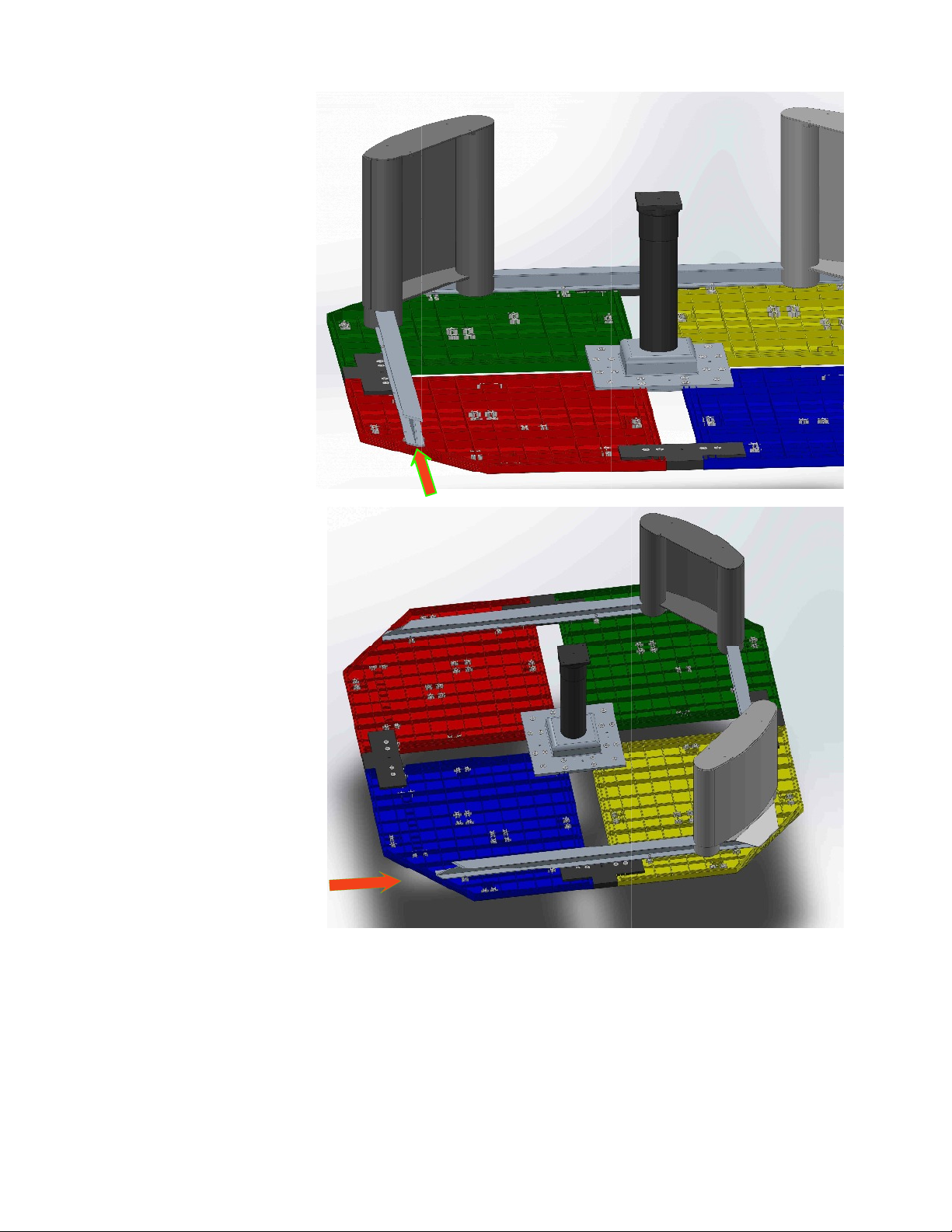

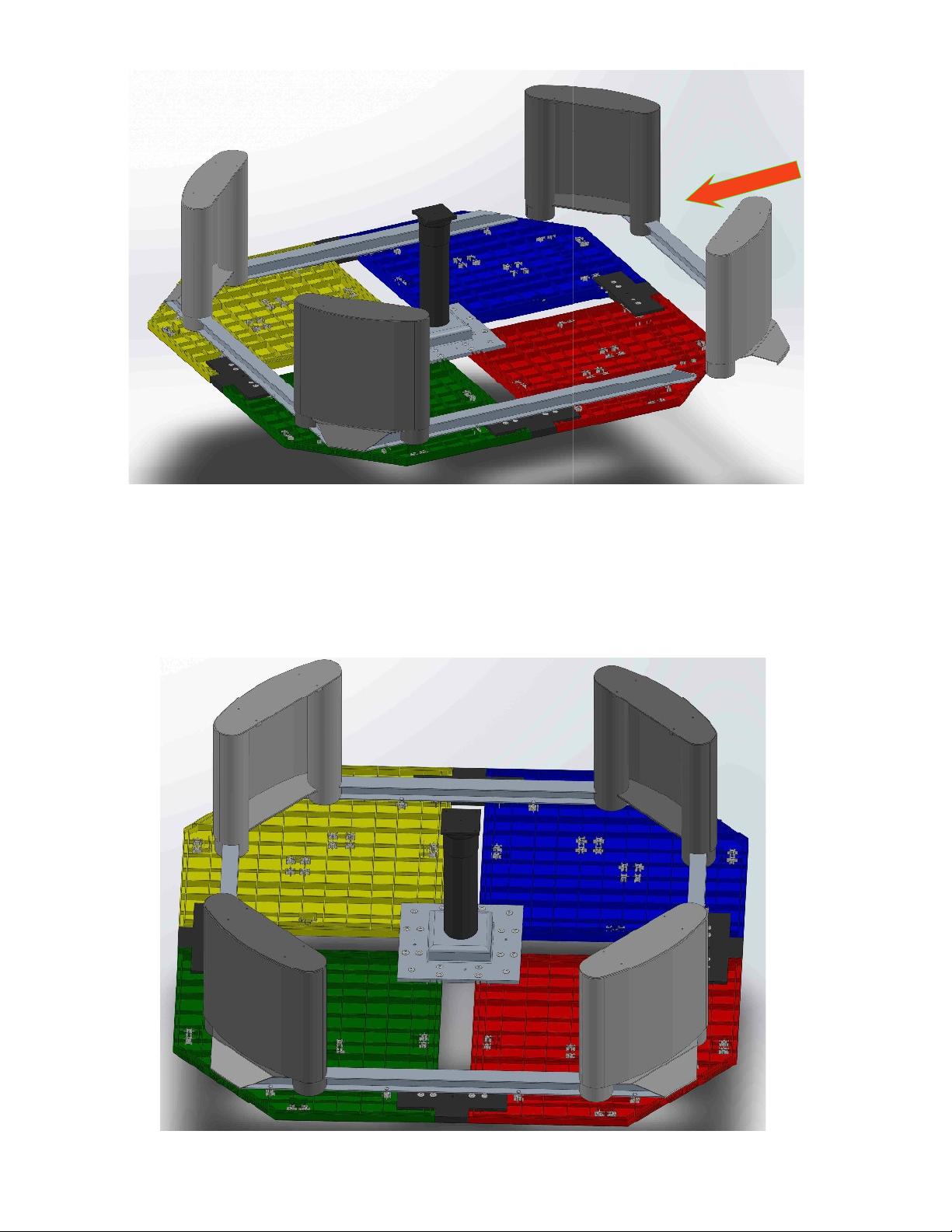

Now locate the center post. This will be

placed in the center of the four tables with

the large end down. It should fit snugly

between the table tops. Fig. 5.

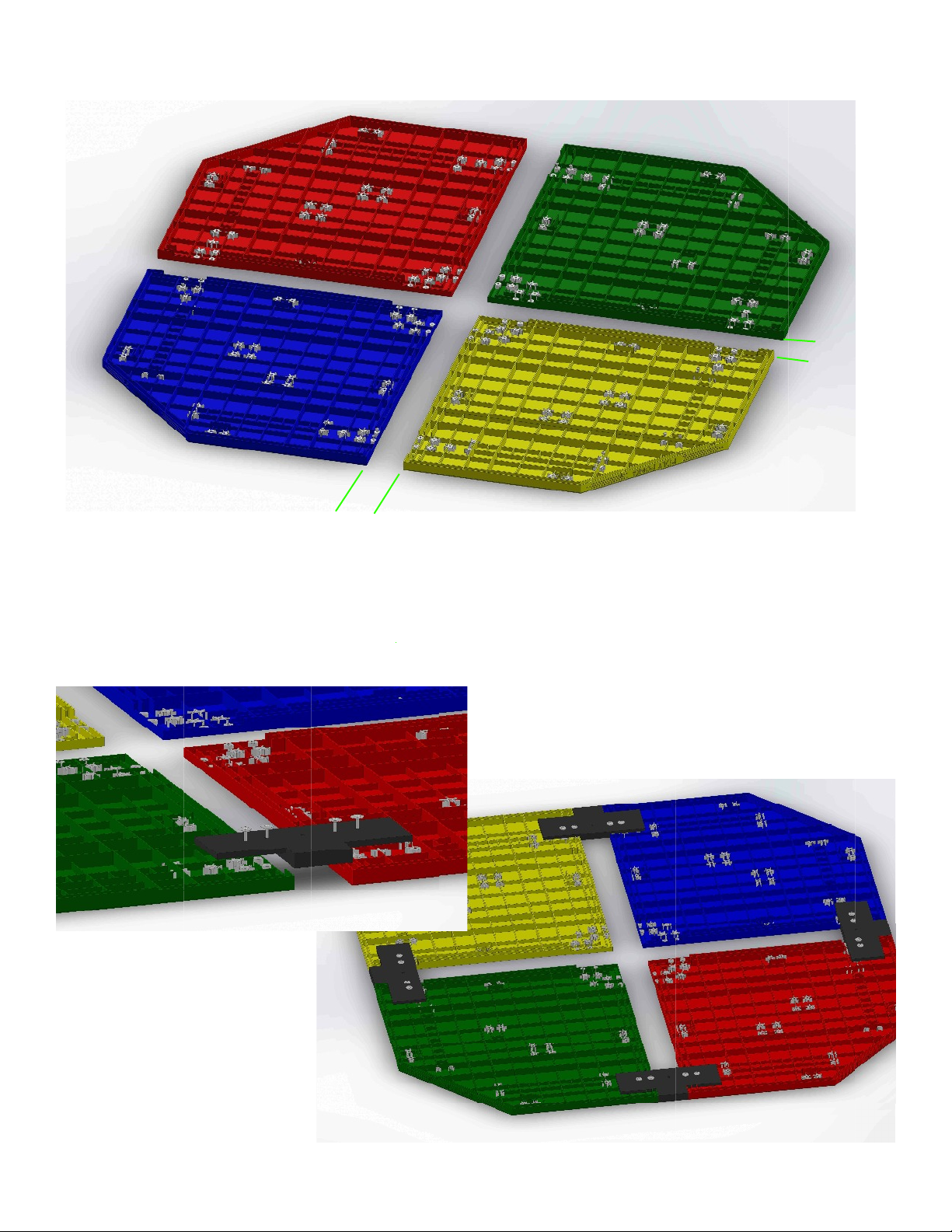

Four 8 mm x 30 mm screws with large

washers should be screwed into the molded

nuts that are in the corners of each of the

four table tops. THESE SHOULD BE

ONLY TIGHTENED LOOSELY. Fig. 6.

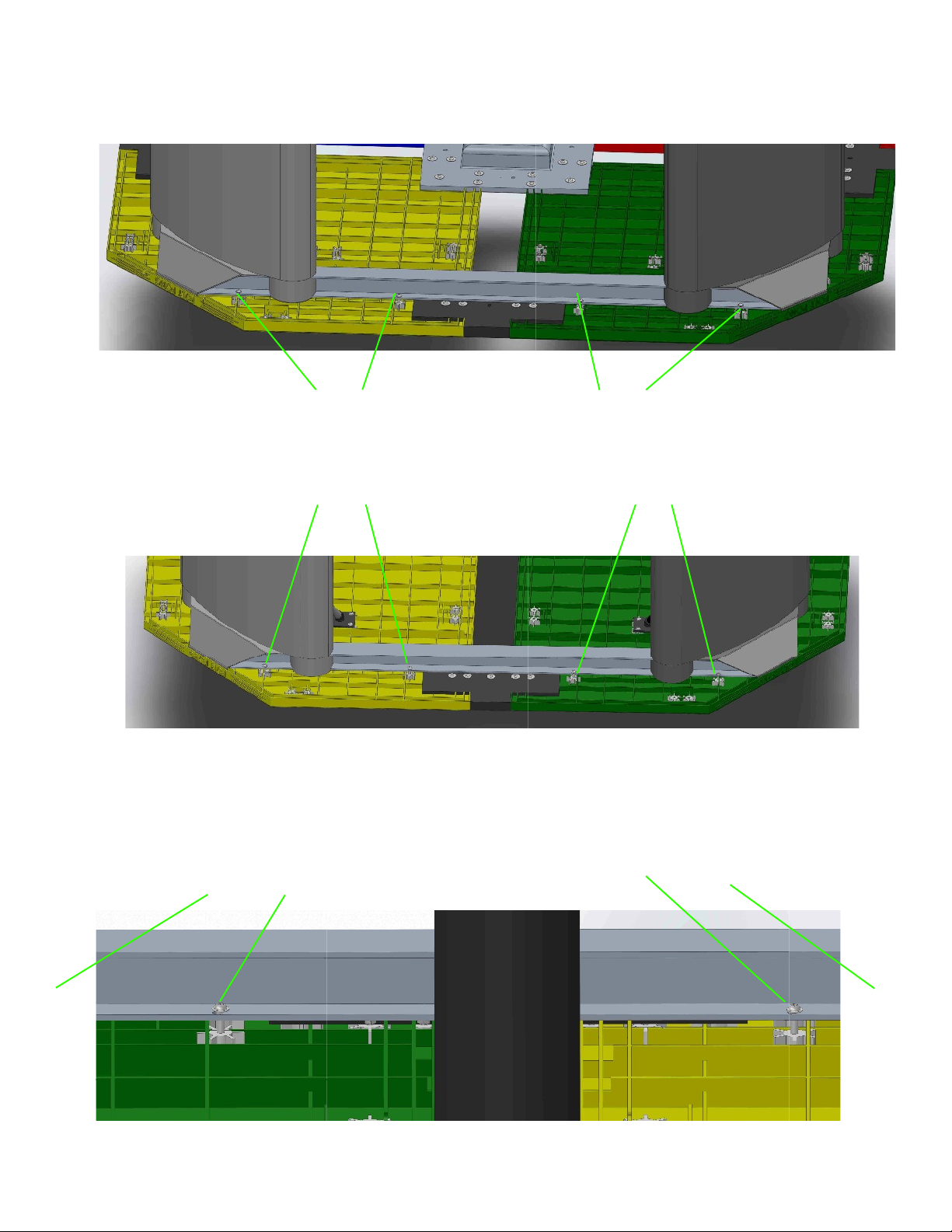

You may now tighten all loose screws

in the table joiners and the four screws

in the center post. Now add sixteen

more 8 mm x 30 mm screws and large

washers to the remaining holes in the

center post, using four per table top.

Cinch these screws up tightly. Your

assembly should now look like Fig. 7.

Fig. 6

Fig. 5

NOW CHECK AGAIN TO MAKE SURE

THAT THE DISTANCE BETWEEN EACH

TABLE TOP AND ITS ADJOINING TWO

TABLE TOPS IS EXACTLY 6 INCHES.

ALSO SIGHT ALONG THE OUTER

EDGES OF THE FOUR TABLE TOPS

AND INSURE THAT THEY ARE IN

PERFECT ALIGNMENT.

Fig. 7

NOTE: Use both large

and small washers as

shown in this picture

for the 20 bolts in this

page.