710

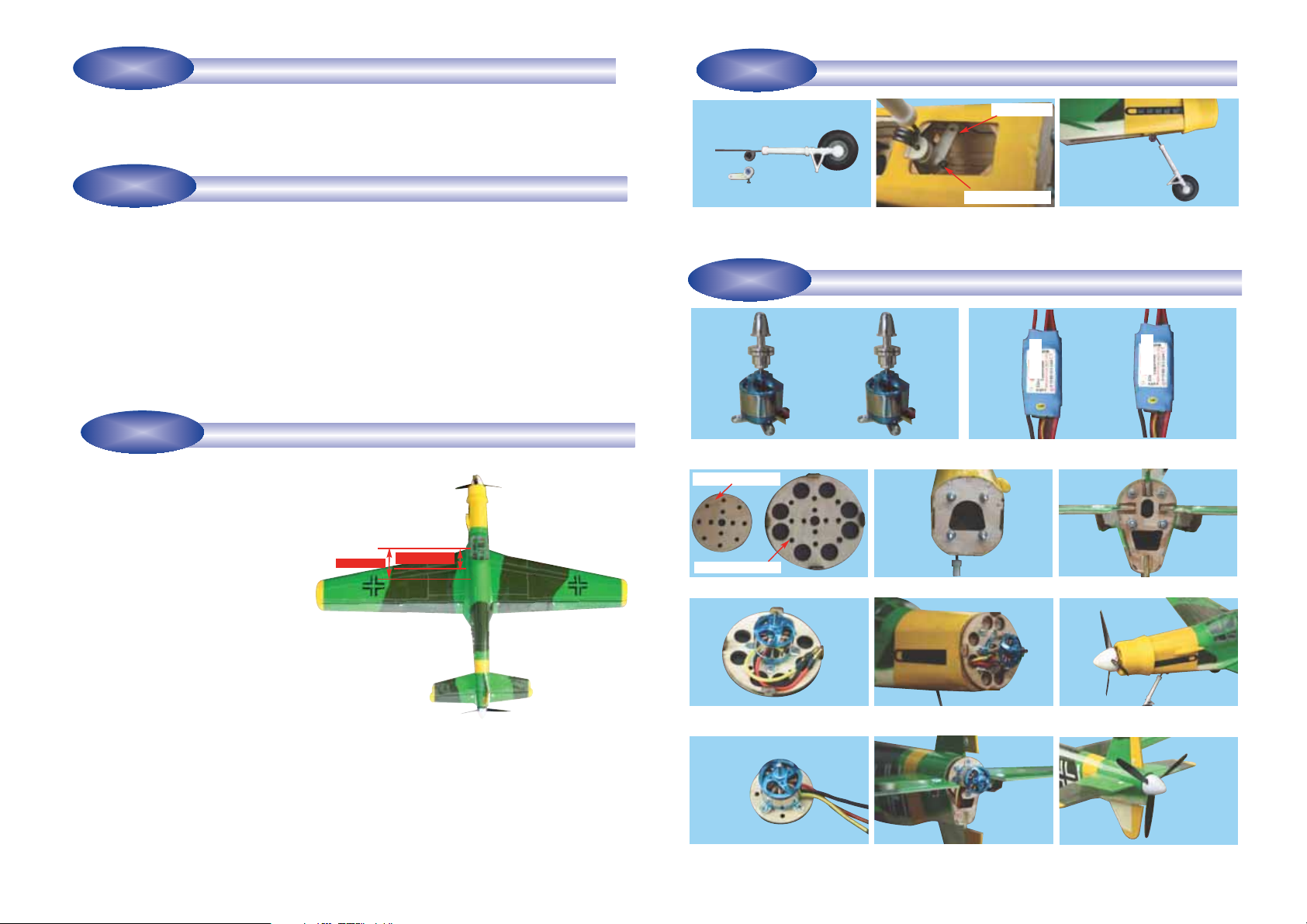

10A- Nose gear assembly 10C- Nose gear assembly installed to

the fuselage (side view)

10B- Insert the nose gear steering

control arm to the EZ connector then

insert the nose gear assembly into

the nose gear bearing then tighteng

the control arm screw

11C- Front and rear motor mount

11F- Mount the brushless motor to

the front motor mount

11I- Mount the brushless motor to the

rear motor mount

11G-The front motor mount with the

motor install to the nose

11H- Cowl,propeller and spinner are

installed to the nose

11H- Cowl,propeller and spinner

installed to the rear end

11D- Front motor location 11E- Read motor mount location

11B- The pair of the suitable ESC come with motor

11A- Front and rear brushless motors are same 150 watts

brushless motor recommended

INSTALL THE NOSE GEAR

STAGE 10

INSTALLING THE ELECTRIC MOTOR AND ESC

STAGE 11

Control arm screw

Front motor mount

Rear motor mount

EZ connector

E

S

C

E

S

C

11G-The rear motor mount with the

motor install to the rear end

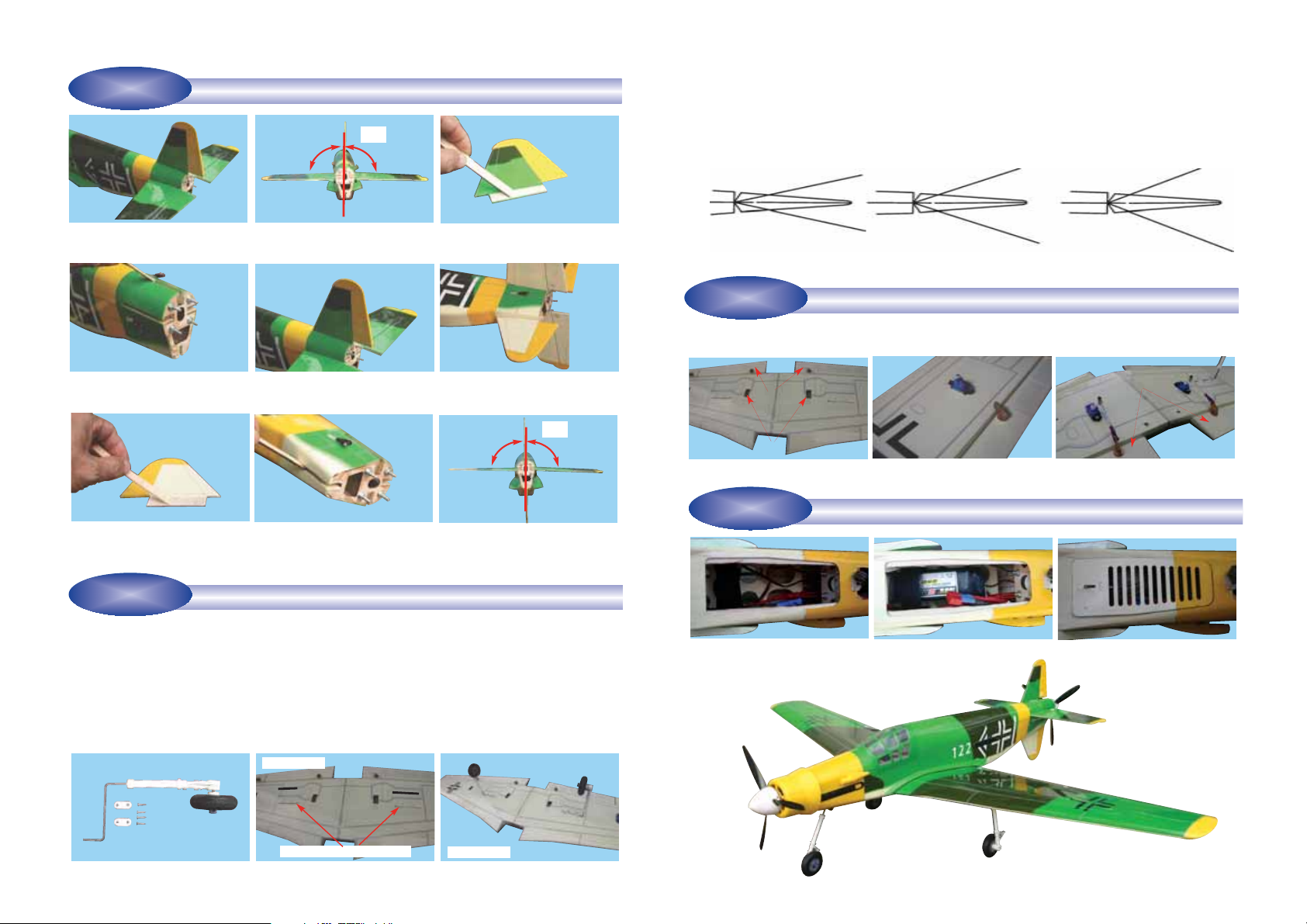

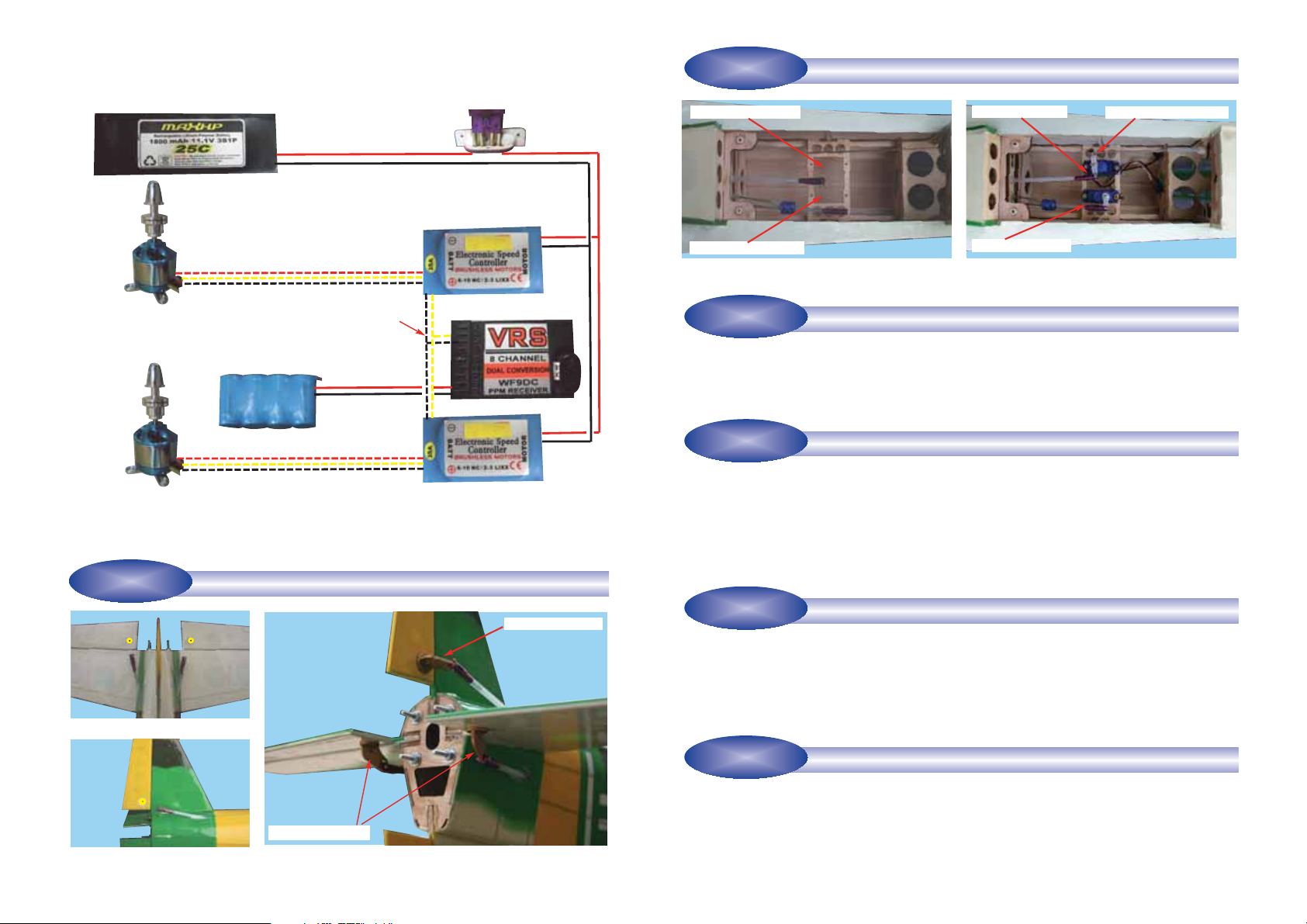

CONFIRM RADIO OPERATION

STAGE 18

Step 18.1 Consult your radio manual for instructions about

testing and operating your radio system.

Step 18.2 Pay particular attention to charging your batter-

ies and range testing your system before and after each

flight.

Step 18.3 Check that all controls are working correctly

before and after each flight.

BALANCING THE AIRCRAFT

STAGE 19

Step 19.1 The CG for your DO 335 is located at 3.1/2 in to

4 in (87mm - 102mm) back from the leading edge of the

wing when the wing has been attached to the fuselage as

per illustration 20A.

Step 19.2 For the initial flight, the CG should be located at

3.1/2 (87mm) back from the leading edge of the wing when

the wing has been attached to the fuselage.

Step 26.3 The CG is measured with the engine,radio gear

and all other components installed

Step 26.4 Set up the CG as it will be when you fly it.

Step 26.5 It is very important to have the CG correct. Flying

your model with the CG too far back will likely lead to loss

of control and a crash. If you discover that after you have

assembled your model and installed your radio, motor and

battery that the CG of your model is incorrect you must

bring the CG to the correct location by doing the following

BEFORE FLYING :

- Move the battery pack fore or aft

- Move other components fore or aft

- Change engine to a lighter or heavier model

- Add weight to the nose or tail. If adding it to the nose,try

to make it useful by going to a heavier duty engine or

adding a spinner with a heavy metal backing plate. As a last

resort, add stick on “dead” weight where appropriate

CONFIRM MECHANICAL INTEGRITY

STAGE 20

Step 20.1 Once you have confirmed that the

CG is correct, you should do a thorough review

of the entire model before your first flight.

Check everything twice! Every hook up, every

coupling, everything! Do it twice!!

Step 20.2 Before your first flight, have an

experienced flyer review your work. Do not fly

your model until it has been checked out by a

third party who knows how to fly and how to

set up a model aircraft. Do not fly alone. Seek

experienced help.

Step 20.3 Once you have completed your first

flight, get in the habit of checking your model over

before and after each flight! Don’t fly if you find

something that is not right!

3.1/2in (152mm)

4in (102mm)

27A - CG location

CONTROL SURFACE THROW SPECIFICATIONS:

The throws are measured at the widest part of the control

surface. Adjust the position of the pushrods at the control

and/or servo horns to control the amount of throw. You may

also use ATV's if your radio has them but the mechanical

linkages should still be set so that the ATV's are near 100%

for best servo resolution.