CONTENTS

1. GENERAL..............................................................................................................4

1.1 Safety instructions.................................................................................................................................... 4

1.2 Labeling .................................................................................................................................................... 4

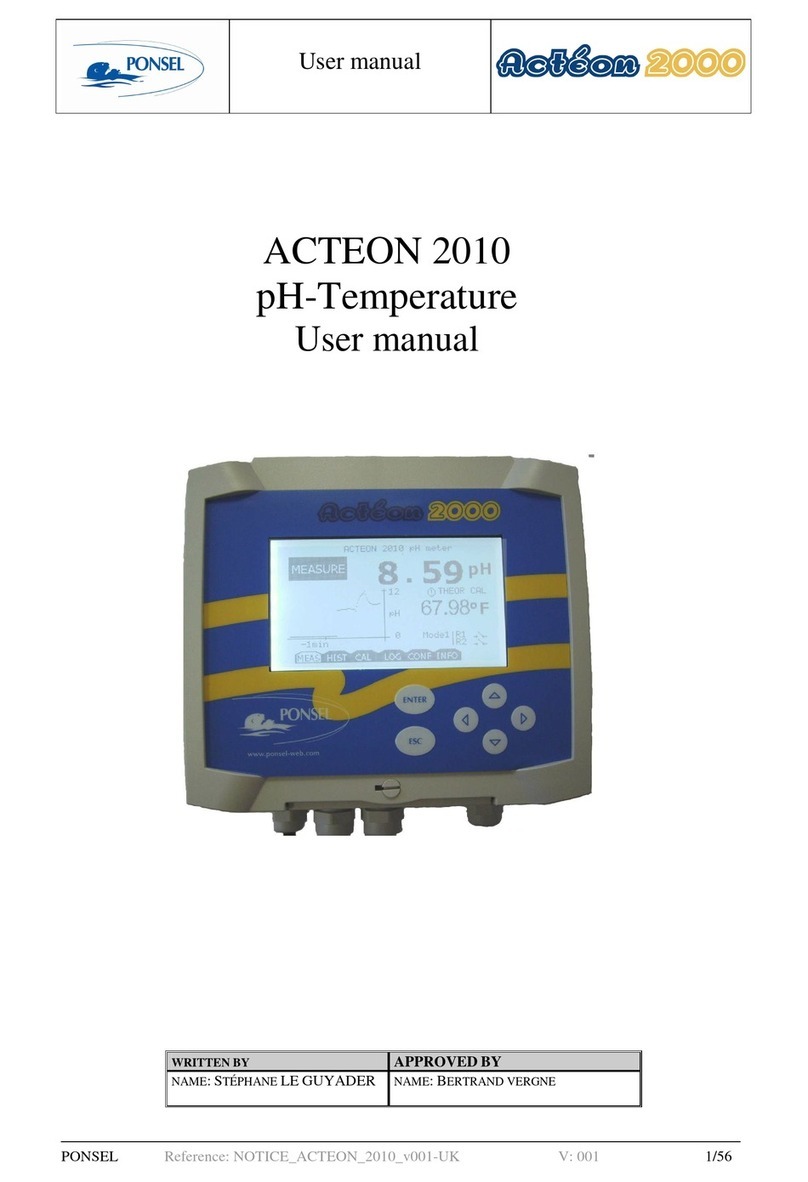

2. DESCRIPTION OF THE EQUIPMENT...................................................................5

2.1 ACTEON 5000 transmitter. ........................................................................................................................... 5

2.1.1 General description. ................................................................................................................................... 5

2.1.2 Technical characteristics. ........................................................................................................................... 5

2.2 Digital sensors.................................................................................................................................................. 6

2.2.1 OPTOD sensor: dissolved oxygen (optical technology). ........................................................................... 6

2.2.2 PHEHT sensor: pH and temperature.......................................................................................................... 7

2.2.3 EHAN sensor: Redox and temperature. ..................................................................................................... 8

2.2.4 NTU sensor: Turbidity in NTU-mg/l. ........................................................................................................ 9

2.2.5 C4E sensor: 4-electrode conductivity....................................................................................................... 10

2.2.6 CTZN sensor: inductive conductivity. ..................................................................................................... 11

2.2.7 VB5 sensor: Sludge Blanket detection..................................................................................................... 12

2.2.8 MES5 sensor: Sludge Blanket detection, Suspended Solid, Turbidity..................................................... 13

3. INSTALLATION ...................................................................................................14

3.1 Description and mounting of the controller................................................................................................ 14

3.1.1 Description of the front face..................................................................................................................... 14

3.1.2 Equipment required.................................................................................................................................. 14

3.1.3 Outline drawings of the ACTEON 5000.................................................................................................. 15

3.2 Electrical connections. .................................................................................................................................. 16

3.2.1 Safety instructions –Installation.............................................................................................................. 16

3.2.2 Description of the wiring.......................................................................................................................... 17

4. USER INTERFACE..............................................................................................20

4.1 Home screen................................................................................................................................................... 20

4.2 Navigation icons. ........................................................................................................................................... 21

5. SETTING UP........................................................................................................22

5.1 Initial start-up. .............................................................................................................................................. 22

5.2 Installation of digital sensors........................................................................................................................ 23

5.3 Selection of the parameters. ......................................................................................................................... 23

6. PROGRAMMING .................................................................................................25

6.1 Main menu..................................................................................................................................................... 25

6.2 Description of the menus. ............................................................................................................................. 25

6.2.1 Configuring the digital inputs................................................................................................................... 25

6.2.2 Configuring the On/Off inputs. ................................................................................................................ 32

6.2.3 Configuring the Analog inputs................................................................................................................. 33

6.2.4 Configuring the ACTEON 5000. ............................................................................................................. 37

6.2.5 Configuring the Analog outputs............................................................................................................... 38

6.2.6 Configuring the relay outputs................................................................................................................... 41

6.2.7 Configuring the Recording output............................................................................................................ 44

7. MAINTENANCE...................................................................................................45

7.1 Maintaining the transmitter:........................................................................................................................ 45

7.2 Maintenance of digital sensors:.................................................................................................................... 46