SMAR TP303 Manual

,

Profibus Simatic www.esma-rt.ru

web: www.esma-rt.ru

www.esma-rt.ru

Specifications and information are subject to change without notice.

Up-to-date address information is available on our website.

smar

Introduction

III

INTRODUCTION

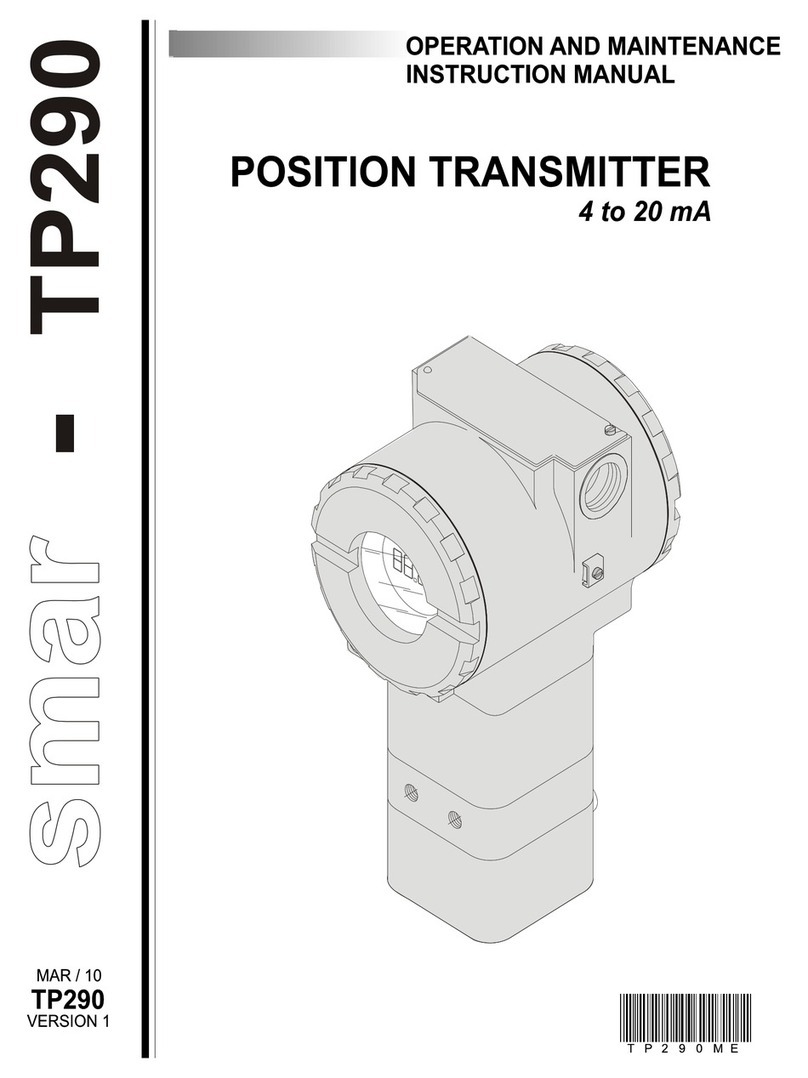

The TP303 is from the first generation of Profibus-PA devices. It is a transmitter for position

measurements. It can measure displacement or movement of rotary or linear type. The digital

technology and communication provide an easy interface between the field and control room and

several interesting features that considerably reduce the installation, operation and maintenance

costs.

The TP303 is versatile and reliable, and has very high accuracy. It may be used for control valve

stem position measurement, or in any other position sensing application such as louvers, dampers,

crushers, etc.

Since the TP303 uses a non-contact magnetic coupling for position sensing, it less sensitive to

vibration than other solutions, resulting in longer operational life. Deadband due to mechanical

imprecision is avoided. The TP303 mounts to any linear or rotary valve, actuator or a variety of other

devices through the use as VDI/VDE and IEC/NAMUR etc.

The TP303 is very versatile; users can standardize one position indicator for all different kinds of

control valves and other machines, keeping spares and training to a minimum.

The TP303 is part of Smar's complete 303 line of Profibus-PA devices.

Some of the advantages of bi-directional digital communications are known from existing smart

transmitter protocols: Higher accuracy, multi-variable access, remote configuration and diagnostics,

and multi-dropping of several devices on a single pair of wires.

The system controls variable sampling, algorithm execution and communication to optimize the

usage of the network, not loosing time. Thus, high closed loop performance is achieved.

Using Profibus technology, with its capability to interconnect several devices, very large control

schemes can be constructed. In order too be user friendly the function block concept was

introduced.

The TP303, like the rest of the 303 family, has some Function Blocks built in, like Analog Input and

Totalizer Block.

The need for implementation of Fieldbus in small as well as large systems was considered when

developing the entire 303 line of Profibus-PA devices. They have common features and can be

configured locally using a magnetic tool, eliminating the need for a configurator or console in many

basic applications.

The TP303 is available as a product on its own, but also replaces the circuit board for the TP301.

They use the same sensor board. Refer to the maintenance section of this manual for instructions

on upgrading. The TP303 uses the same hardware and housing for the TP302.The TP303 is part of

Smar's 303 Series of Profibus-PA devices.

The TP303, like its predecessor TP301, has some built-in blocks, eliminating the need for a

separate control device. The communication requirement is considerably reduced, and that means

less dead time and tighter control is achieved, not to mention the reduction in cost. They allow

flexibility in control strategy implementation.

Get the best results of the TP303 by carefully reading these instructions.

TP303 - Operation, Maintenance and Instructions Manual

IV

NOTE

This Manual is compatible with version 1.XX, where 1 denotes software version and XX software release. The

indication 1.XX means that this manual is compatible with any release of software version 1.

Waiver of responsibility

The contents of this manual abides by the hardware and software used on the current equipment

version. Eventually there may occur divergencies between this manual and the equipment. The

information from this document are periodically reviewed and the necessary or identified corrections

will be included in the following editions. Suggestions for their improvement are welcome.

Warning

For more objectivity and clarity, this manual does not contain all the detailed information on the

product and, in addition, it does not cover every possible mounting, operation or maintenance

cases.

Before installing and utilizing the equipment, check if the model of the acquired equipment complies

with the technical requirements for the application. This checking is the user’s responsibility.

If the user needs more information, or on the event of specific problems not specified or treated in

this manual, the information should be sought from Smar. Furthermore, the user recognizes that the

contents of this manual by no means modify past or present agreements, confirmation or judicial

relationship, in whole or in part.

All of Smar’s obligation result from the purchasing agreement signed between the parties, which

includes the complete and sole valid warranty term. Contractual clauses related to the warranty are

not limited nor extended by virtue of the technical information contained in this manual.

Only qualified personnel are allowed to participate in the activities of mounting, electrical connection,

startup and maintenance of the equipment. Qualified personnel are understood to be the persons

familiar with the mounting, electrical connection, startup and operation of the equipment or othe

r

similar apparatus that are technically fit for their work. Smar provides specific training to instruct and

qualify such professionals. However, each country must comply with the local safety procedures,

legal provisions and regulations for the mounting and operation of electrical installations, as well as

with the laws and regulations on classified areas, such as intrinsic safety, explosion proof, increased

safety and instrumented safety systems, among others.

The user is responsible for the incorrect or inadequate handling of equipments run with pneumatic

or hydraulic pressure or, still, subject to corrosive, aggressive or combustible products, since thei

r

utilization may cause severe bodily harm and/or material damages.

The field equipment referred to in this manual, when acquired for classified or hazardous areas, has

its certification void when having its parts replaced or interchanged without functional and approval

tests by Smar or any of Smar authorized dealers, which are the competent companies for certifying

that the equipment in its entirety meets the applicable standards and regulations. The same is true

when converting the equipment of a communication protocol to another. In this case, it is necessary

sending the equipment to Smar or any of its authorized dealer. Moreover, the certificates are

different and the user is responsible for their correct use.

Always respect the instructions provided in the Manual. Smar is not responsible for any losses

and/or damages resulting from the inadequate use of its equipments. It is the user’s responsibility to

know and apply the safety practices in his country.

Table of Contents

V

TABLE OF CONTENTS

SECTION 1 - INSTALLATION.................................................................................................................. 1.1

GENERAL...................................................................................................................................................................................1.1

HOUSING ROTATION................................................................................................................................................................1.5

BUS TOPOLOGY AND NETWORK CONFIGURATION.............................................................................................................1.6

INTRINSIC SAFETY BARRIER ..................................................................................................................................................1.7

JUMPER CONFIGURATION ......................................................................................................................................................1.7

POWER SUPPLY .......................................................................................................................................................................1.7

DISASSEMBLY PROCEDURE...................................................................................................................................................1.8

ASSEMBLY PROCEDURE.........................................................................................................................................................1.9

SECTION 2 - OPERATION....................................................................................................................... 2.2

FUNCTIONAL DESCRIPTION – HALL SENSOR.......................................................................................................................2.2

FUNCTIONAL DESCRIPTION – ELECTRONICS ......................................................................................................................2.2

HALL EFFECT SENSOR............................................................................................................................................................2.3

SECTION 3 - CONFIGURATION.............................................................................................................. 3.1

TRANSDUCER BLOCK..............................................................................................................................................................3.1

TRANSDUCER BLOCK DIAGRAM FOR POSITION TRANSMITTER........................................................................................3.1

TRANSDUCER BLOCK PARAMETER DESCRIPTION..............................................................................................................3.2

TRANSDUCER BLOCK PARAMETER ATTRIBUTES................................................................................................................3.4

TRANSDUCER BLOCK VIEW OBJECT.....................................................................................................................................3.5

HOW TO CONFIGURE THE TRANSDUCER BLOCK................................................................................................................3.6

HOW TO CONFIGURE THE ANALOG INPUT BLOCK..............................................................................................................3.7

TP303 CYCLICAL CONFIGURATION........................................................................................................................................3.9

HOW TO CONFIGURE THE TOTALIZER BLOCK...................................................................................................................3.10

LOWER AND UPPER TRIM .....................................................................................................................................................3.12

POSITION TRIM - TP303..........................................................................................................................................................3.13

TEMPERATURE TRIM .............................................................................................................................................................3.14

BACKUP RESTORE.................................................................................................................................................................3.15

TRANSDUCER DISPLAY – CONFIGURATION .......................................................................................................................3.15

DISPLAY TRANSDUCER BLOCK............................................................................................................................................3.16

DEFINITION OF PARAMETERS AND VALUES.......................................................................................................................3.16

PROGRAMMING USING LOCAL ADJUSTMENT ....................................................................................................................3.19

SECTION 4 - MAINTENANCE PROCEDURES........................................................................................ 4.1

GENERAL...................................................................................................................................................................................4.1

DISASSEMBLY PROCEDURE...................................................................................................................................................4.2

TRANSDUCER ...........................................................................................................................................................................4.2

REASSEMBLY PROCEDURE....................................................................................................................................................4.3

ELECTRONIC CIRCUIT..............................................................................................................................................................4.3

UPGRADING TP301 TO TP303 .................................................................................................................................................4.3

SECTION 5 - TECHNICAL CHARACTERISTICS .................................................................................... 5.1

FUNCTIONAL SPECIFICATIONS ..............................................................................................................................................5.1

PERFORMANCE SPECIFICATIONS..........................................................................................................................................5.1

PHYSICAL SPECIFICATIONS....................................................................................................................................................5.2

ORDERING CODE......................................................................................................................................................................5.2

APPENDIX A – SRF – SERVICE REQUEST FORM................................................................................A.1

RETURNING MATERIALS......................................................................................................................................................... A.2

APPENDIX B – SMAR WARRANTY CERTIFICATE ...............................................................................B.1

TP303 - Operation, Maintenance and Instructions Manual

VI

Table of Contents

VII

I

nsta

ll

at

i

on

Fl

owc

h

art

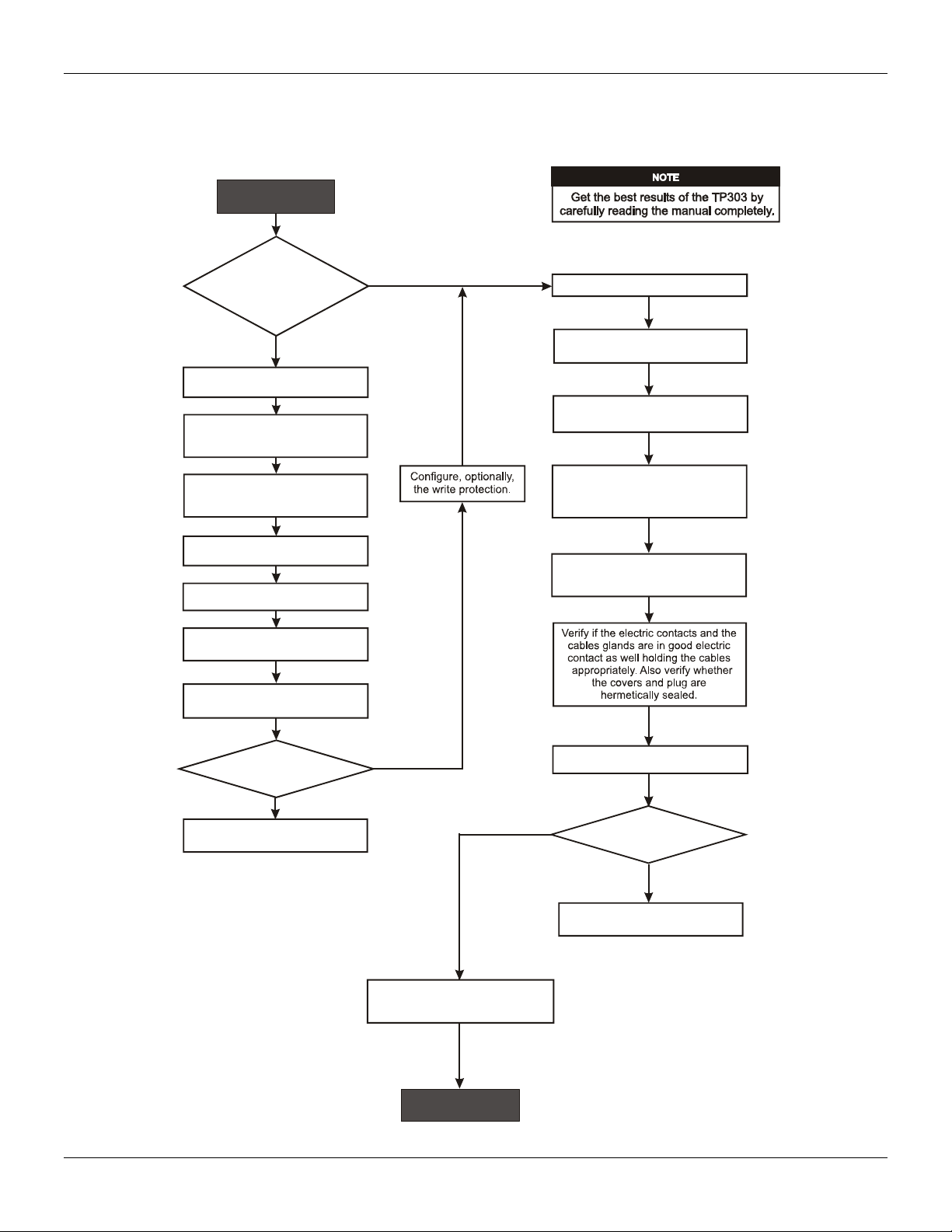

Quick Installation Guide

Has the transmitter

been configured

in bench for the

application ?

Configure the transmitter

( section 1 and section 3).

Start

Field Installation.

Install the transmitter in

protected areas.

Install the transmitter (mechanically

and electrically) according to the

application, verifying the most

appropriate position of the LCD.

Verify area classification and

its respective practices.

NO

YES

Configure Fail Safe value

(Section 3).

Configure Damping (Section 3).

Configure the indication in LCD

(Section 3).

Configure the user unit in case

of specific measurements.

Is the measurement

OK ?

NO

YES

Is ?

the

measuring ok

OK

NO

Using the GSD file, configure

the cyclic data in the system

configuration tool (Section 3)

YES

Consult the manual

Section 4 - Maintenance.

Consult the manual

Section 4 - Maintenance.

Dislocate the system to

upper position, execute the

upper position trim for 100%.

Dislocate the system to

lower position, execute the

lower position trim for 0%.

Power the transmitter appropriately.

Fix the transmitter magnet

in a position that allows to the

sensor to travel all magnet range.

TP303 - Operation, Maintenance and Instructions Manual

VIII

Section 1

1.1

INSTALLATION

The overall accuracy of measurement and control depends on several variables. Although the

converter has an outstanding performance, proper installation is essential, in order to maximize its

performance.

Among all factors, which may affect converter accuracy environmental conditions are the most

difficult to control. There are, however, ways of reducing the effects of temperature, humidity and

vibration.

In warm environments, the transmitter should be installed to avoid, as much as possible, direct

exposure to the sun. Installation close to lines and vessels subjected to high temperatures should

also be avoided.

Use of sunshades or heat shields to protect the transmitter from external heat sources should be

considered, if necessary.

Humidity is fatal to electronic circuits. In areas subjected to high relative humidity, the O-rings for the

electronics cover must be correctly placed. Removal of the electronics cover in the field should be

reduced to the minimum necessary, since each time it is re-moved; the circuits are exposed to the

humidity. A humidity proof coating protects the electronic circuit, but frequent exposures to humidity

may affect the protection provided. It is also important to keep the covers tightened in place. Every

time they are re-moved, the threads are exposed to corrosion, since painting cannot protect these

parts. Code approved sealing methods on conduit entering the transmitter should be employed.

Although the transmitter is virtually insensitive to vibration, installation close pumps, turbines or

other vibrating equipment should be avoided.

General

MOUNTING

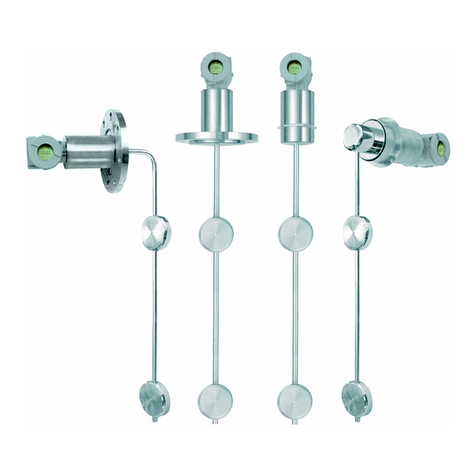

The mounting of transmitter TP303 will depend on type movement, if it is linear or rotary. Two

supports are required for mounting, one for the magnet and the other for the transmitter itself. Smar

may supply then both since they are specified in the order code (See page 4.7)

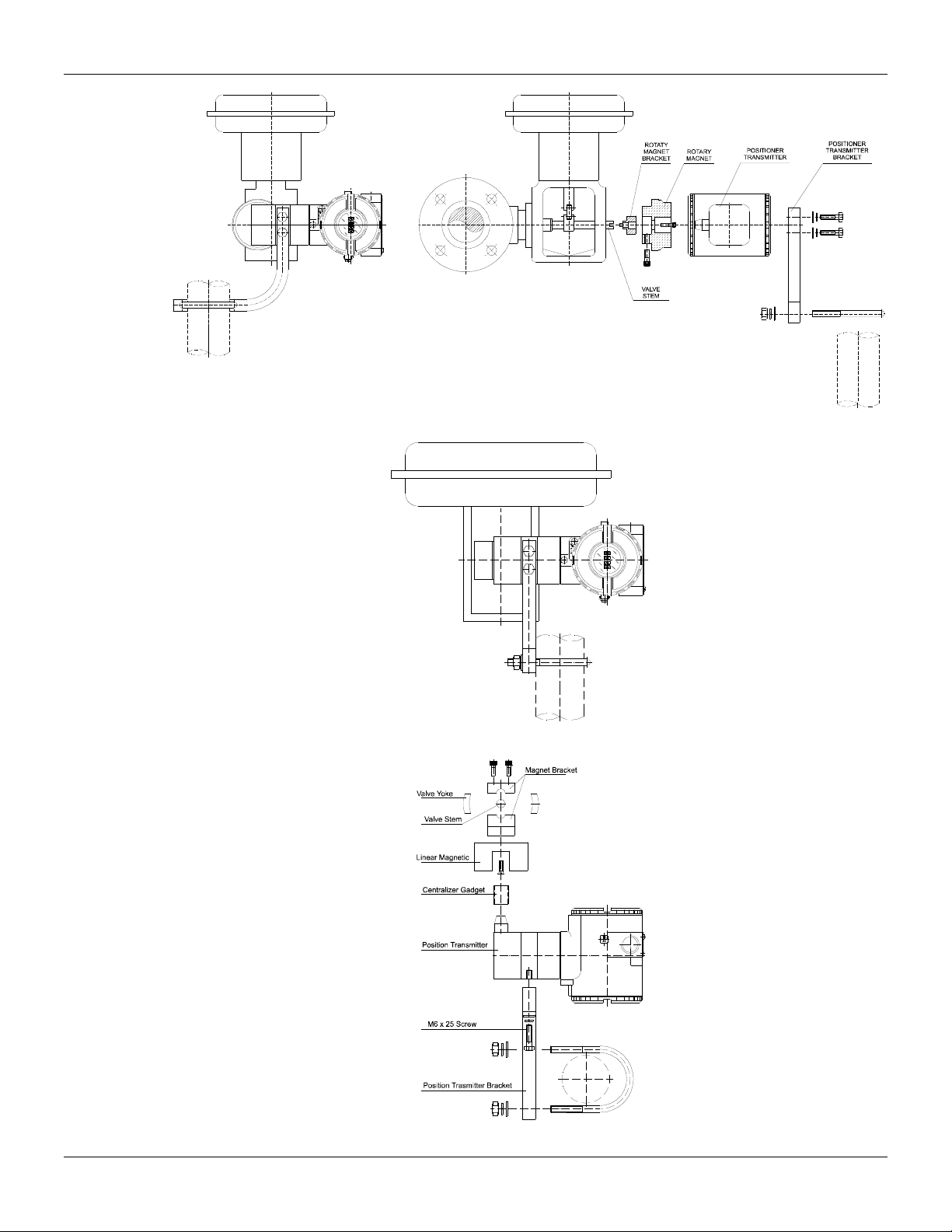

Rotary Movement

Install the magnet on the valve stem using the magnet support (See figure 1.2). Install the

transmitter support on the actuator. Should the actuator be in accordance with standard VDI/VDE

5845, all you have to do is tighten the four screws with the lock washers on the standard support.

For special supports, refer to specify instructions. After installing the support on the actuator, it is

possible to mount transmitter TP303 on the support by means of the four screws with lock washers.

Make sure that the arrow engraved on the magnet coincides with the arrow engraved on the

transmitter when the system is in mid travel. In case the installation of the transmitter or magnet is

altered, or should there be any other modification, the transmitter will require a recalibration.

Linear Movement

Install the magnet on the valve stem using the magnet support (See figure 1.3). Install the

transmitter support on the actuator. The actuator support may be secured in place as per standard

NAMUR/IEC 536-4 or in accordance with user specified boring. Install the transmitter on the support

and tighten the four screws in the threaded bores located on the side opposite to the sensor (Figure

1.3). Use lock washers in order to prevent screw slackening.

Make sure that the support is not obstructing the exhaustion outlets.

TP303 - Operation, Maintenance and Instructions Manual

1.2

NOTE

Make sure that arrow engraved on the magnet coincides with the arrow engraved on the position transmitter

when the system is in mid travel. The magnet mounting in relation to the hall sensor:

1 . Must not have attrict between the internal magnet face and the hall sensor salience during the travel

(rotary or linear), through the magnet.

2. The magnet and the salience of hall sensor must not be distant.

A minimum distance of 2mm and a maximum distance of 4mm is recommended between the magnet external

face and the position transmitter face.

Should the installation of the transmitter or magnet be altered, or should there be any other

modification, the transmitter will require a re-calibration.

Installation

1.3

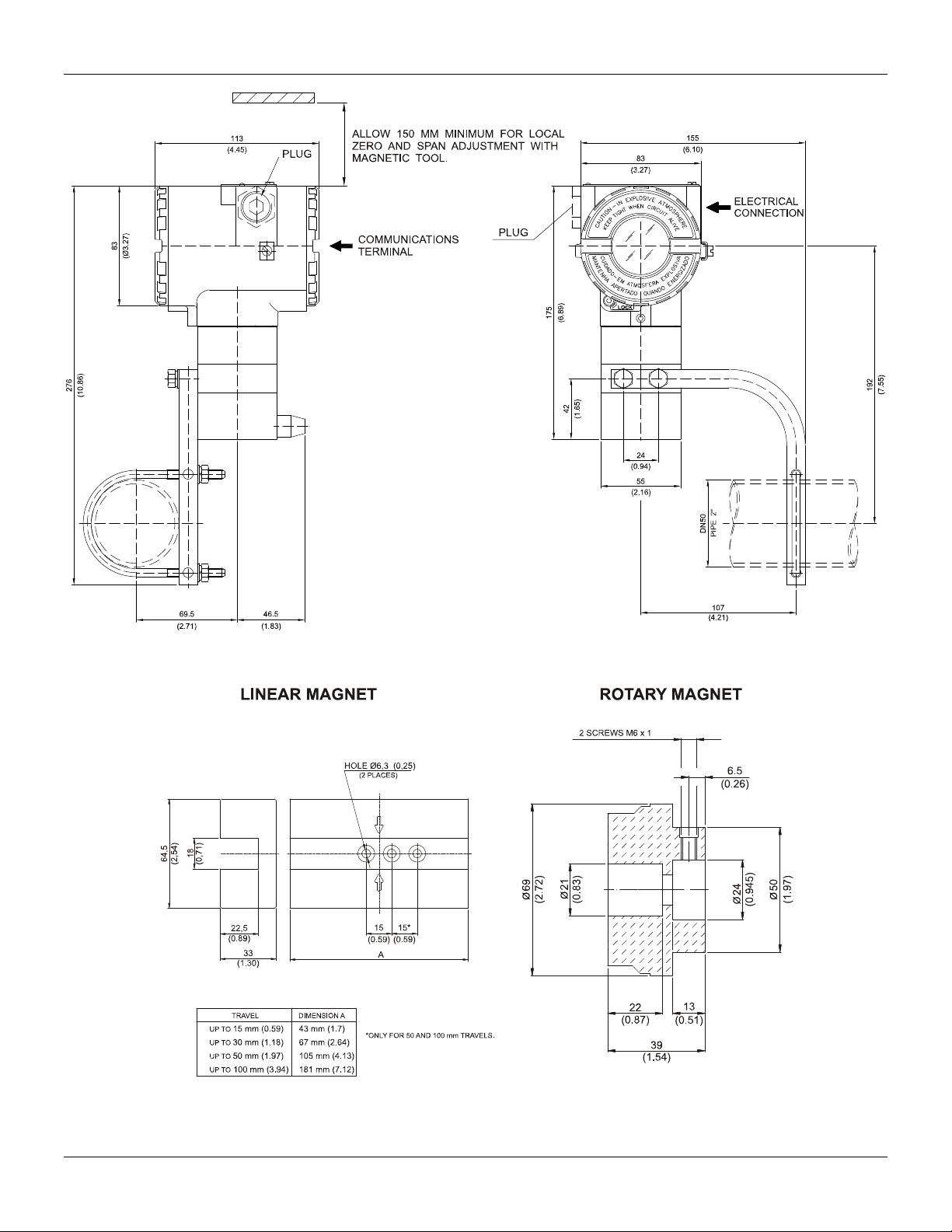

Figure 1.1 – TP303 and Magnet Dimensional Drawing

TP303 - Operation, Maintenance and Instructions Manual

1.4

Figure 1.2 – Transmitter on the Rotary Actuator

Figure 1.3 – Transmitter on the Linear Actuator

Installation

1.5

Housing Rotation

The electronic housing can be rotated in order to better position the digital display. To rotate it, uses

the housing rotation set screw, see figure 1.4.

The local indicator itself can also be rotated. See section 5, figure 5.2.

Electric Wiring

Reach the wiring block by removing the electrical connection cover (figure 1.4). This cover can be

locked closed by the cover locking screw. To release the cover, rotate the locking screw clockwise.

Figure 1.4 – Cover Locking and Housing Rotation Set Screw

The wiring block has screws on which fork or ring-type terminals can be fastened. See figure 1.5.

For convenience there are two ground terminals: one inside the cover and one external, located

close to the conduit entries.

Figure 1.5 – Wiring Block

The TP303 uses the 31.25 kbit/s voltage mode option for the physical signaling. All other devices on

the same bus must use the same signaling. All devices are connected in parallel along the same

pair of wires.

Various types of Fieldbus devices may be connected on the same bus.

The TP303 is powered via the bus. The limit for such devices is according to DP/PA coupler

limitations for one bus for non-intrinsically safe requirement.

In hazardous area, the number of devices may be limited by intrinsically safe restrictions, according

to the DP/PA couples and barriers limitations.

The TP303 is protected against reverse polarity, and can withstand ±35 VDC without damage, but it

will not operate when in reverse polarity.

TP303 - Operation, Maintenance and Instructions Manual

1.6

WARNING

HAZARDOUS AREAS

In hazardous zones with explosion proof requirements the covers must be tightened with at least 7 turns. In

order to avoid moisture or corrosive gases, hand tighten the covers until the O-rings are compressed. Lock the

covers closed with the locking screw.

In hazardous zones with intrinsically safe or non-incentive requirements, the circuit entity parameters and

applicable installation procedures must be observed.

Cable access to wiring connections is obtained by the two conduit outlets. Conduit threads should be sealed by

means of code-approved sealing methods. The unused outlet connection should be plugged and sealed

accordingly.

Should other certifications be necessary, refer to the certification or specific standard for installation limitations.

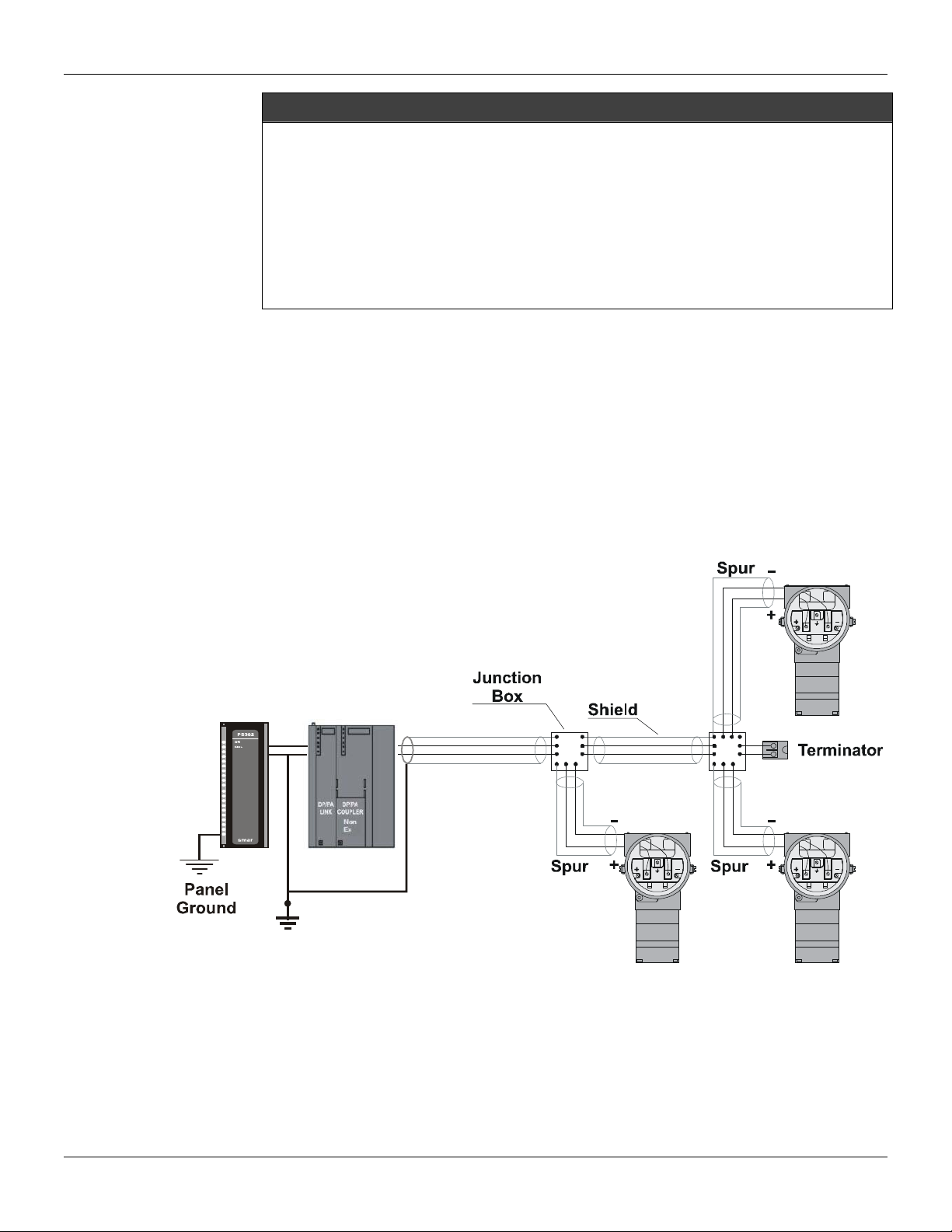

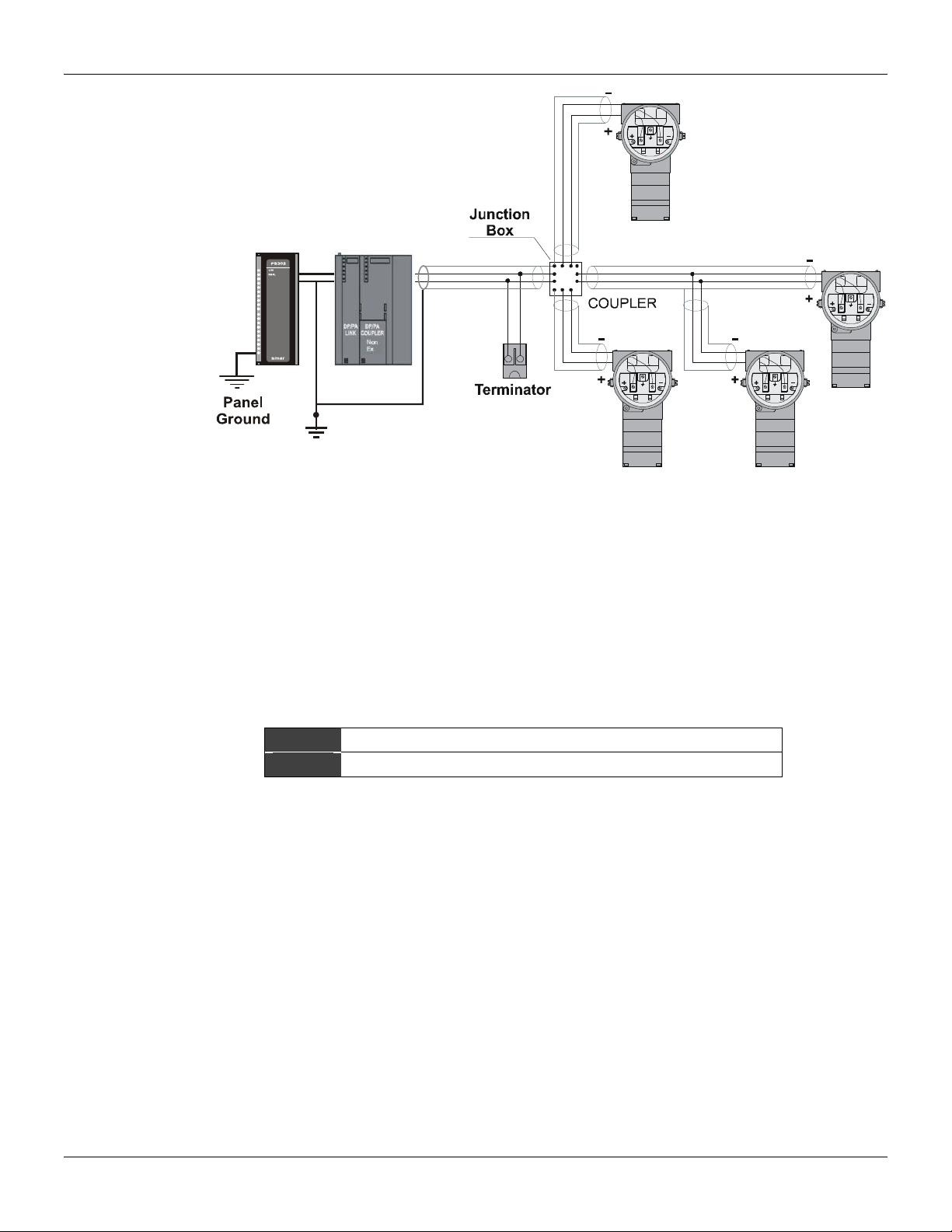

Bus Topology and Network Configuration

Bus and tree topology are supported. Both types have a trunk cable with two terminations. The

devices are connected to the trunk via spurs. The spurs may be integrated in the device giving zero

spur length. A spur may connect more than one device, depending on the length. Active couplers

may be used to extend spur length.

Active repeaters may be used to extend the trunk length.

The total cable length, including spurs, between any two devices in the Fieldbus should not exceed

1900m.

In following figures, the DP/PA link depends on the application needs.

Analog

Ground

+

-+

-

Figure 1.6 - Bus Topology

Installation

1.7

Analog

Ground

+

-+

-

Figure 1.7 - Tree Topology

Intrinsic Safety Barrier

When the Fieldbus is in an area requiring intrinsic safety, a barrier must be inserted on the trunk

between the power supply and the DP/PA coupler, when it is Non-Ex type.

Use of DF47 is recommended.

Jumper Configuration

In order to work properly, the jumpers J1 and W1 located in the TP303 main board must be correctly

configured.

J1 This jumper enables the simulation mode parameter in the AI block.

W1 This jumper enables the local adjustment-programming tree.

Table 1.1 - Description of the Jumpers

Power Supply

The TP303 receives power from the bus via the signal wiring. The power supply may come from a

separate unit or from another device such as a controller or DCS.

The voltage should be between 9 to 32 Vdc for non-intrinsic safe applications.

A special requirement applies to the power supply used in an intrinsically safe bus and depends on

the type of barrier used.

Use of PS302 is recommended as power supply.

Remote Hall Sensor

The remote Hall magnetic sensor is recommended for applications where there are high

temperatures and extreme vibrations applications. It prevents excessive wear of the equipment and,

consequently, the reduction of its useful lifetime.

TP303 - Operation, Maintenance and Instructions Manual

1.8

The electric signals on the remote sensor’s connection cable are of low intensity. Therefore, it is

recommended to install the cable inside a conduit (maximum length 20 meters) away from possible

sources of induction and/or electromagnetic interferences. The cable supplied by Smar is shielded

in order to protect it against electromagnetic interferences. Despite this protection, it is not

recommended for the cable to share the same conduit with other cables. The parts for the sensor’s

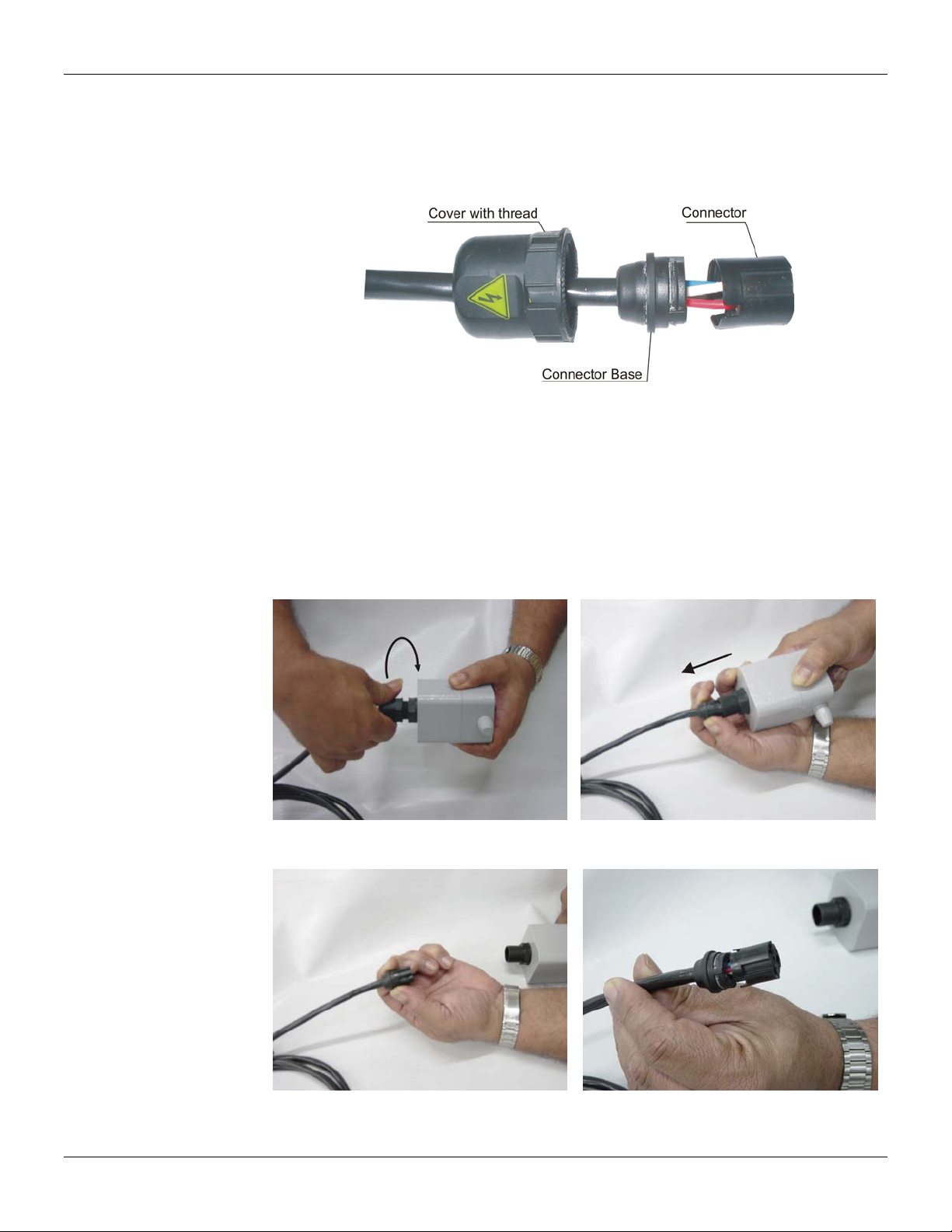

connection cable are:

Figure 1.08 – Hall Sensor Cable and Accessories

Disassembly Procedure

Figures 1.09 to 1.12 show the correct disassembling order for the Hall sensor. The steps for

disassembling are:

1. Unscrew the cover, by turning it on counter-clockwise direction (direction of the arrow) for the

remote Hall side according to figure 1.09.

2. Pull the cable following the arrow as in figure 1.10,

3. Pull the cable connector base, to release it from the block connector, according to figures 1.11

and 1.12.

Figure 1.09 – Disconnecting the cover of

the Hall sensor cable Figure 1.10 – Disconnecting the Hall

sensor cable

Figure 1.11 – Unfastened Connector

Figure 1.12 – Connector with the cable’s

wires maintained in their orifices

Installation

1.9

Figure 1.13 – Wires position in the connector Figure 1.14 – Release the cables’ connector

Assembly Procedure

Mount the components following the sequence:

1. Pass the cable through the cover orifice (Figure 1.15);

2. Pass the cable through the base connector orifice (Figure 1.16);

3. The red, white, and black wires should be inserted in the base connector orifice marked by

numbers beside them, look at figure 1.17 e 1.18.

Figure 1.15 – Assembling the cover Figure 1.16 – Assembling the wire bracket

Orifice to the

white cable Orifice to the

red cable

Orifice to the

black cable

Figure 1.17 – Inserting the wires in the

connector Figure 1.18 – Orifice Cable’s Connector with

numbers beside them

Insert the cable connector in the remote Hall's block connector as figure 1.19. The block connector

has internal saliencies that perfectly fit the groove, in order to prevent errors in the assembly. The

cutting pins inside of the block connector will cut the wire insulators and press against them, thus

establishing the electric contact between the cable and the hall sensor’s circuit.

To finish, fasten the cover to the Hall sensor’s connection (figure 1.20).

TP303 - Operation, Maintenance and Instructions Manual

1.10

Figure 1.19 – Fasten the cover to the remote

Hall Figure 1.20 – Assembly finished

Section 2

2.1

OPERATION

Functional Description – Hall Sensor

Sensor Hall supplies an output voltage proportional to the applied magnetic field. This magnetic

sensor is ideal for use in system of sensor of linear or rotative position. The mechanical vibrations

do not affect Sensor Hall.

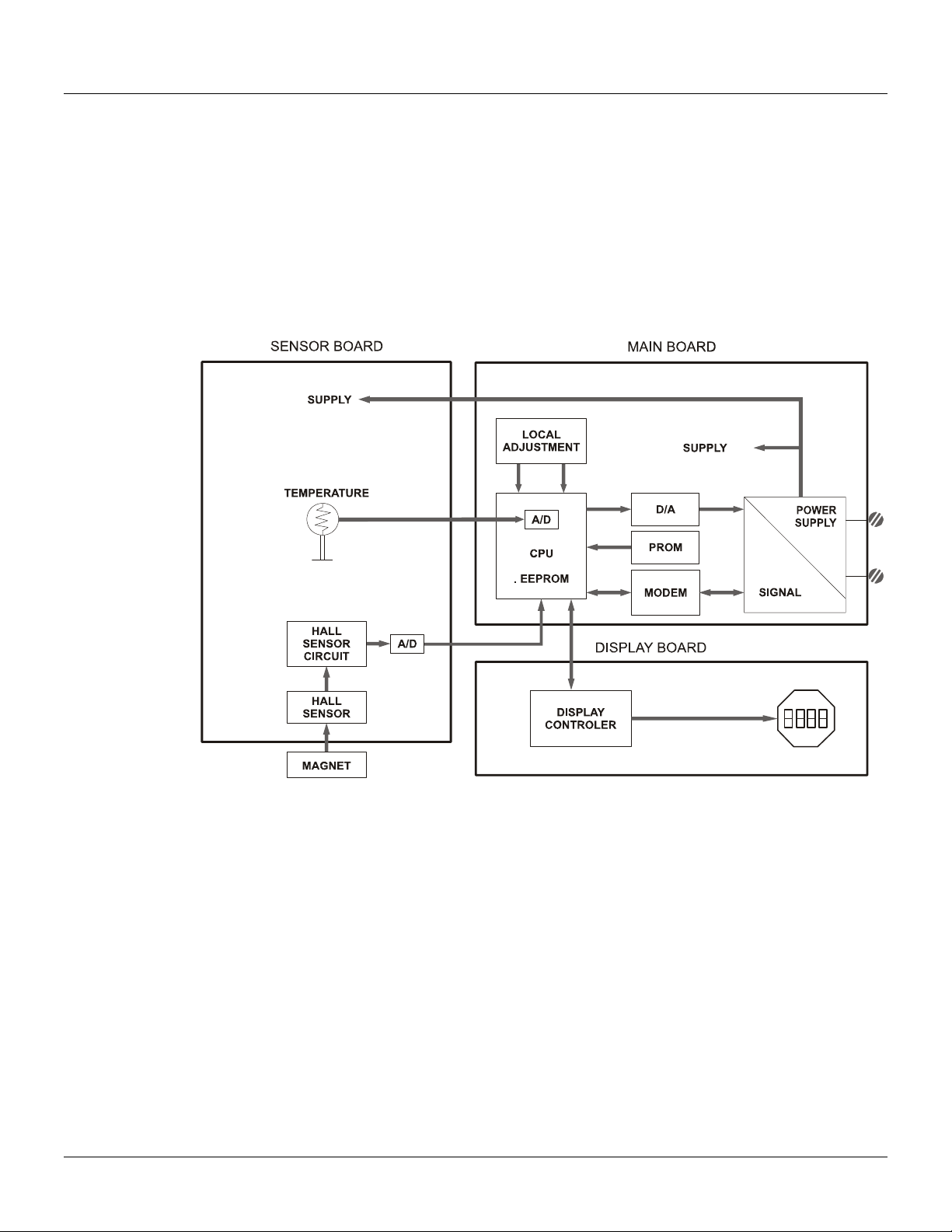

Functional Description – Electronics

Refer to the block diagram. The function of each block is described below.

Figure 2.1 - TP303 Block Diagram Hardware

Oscillator

This oscillator generates a frequency as a function of sensor capacitance.

Signal Isolator

The control signals from the CPU and the signal from the oscillator are isolated to avoid ground

loops.

Central Processing Unit (CPU), RAM, FLASH and EEPROM

The CPU is the intelligent portion of the transmitter, being responsible for the management and

operation of measurement, block execution, self-diagnostics and communication. The program is

stored in a flash memory for easy upgrade and saving data on power-down event occurrence. For

temporary storage of data, there is a RAM. The data in the RAM is lost if the power is switched off,

however the main board has a nonvolatile EEPROM memory where the static data configured that

must be retained is stored. Examples of such data are the following: calibration, links and

identification data.

Fieldbus Modem

Monitors line activity, modulate and demodulate communication signals; inserts and deletes start

and end delimiters, and check integrity of frame received.

TP303 - Operation, Maintenance and Instructions Manual

2.2

Power Supply

Takes power of the loop-line to power the transmitter circuitry.

Power Isolation

Isolates the signals to and from the input section, the power to the input section must be isolated.

Hall Effect Sensor

Measures the position actual to the CPU.

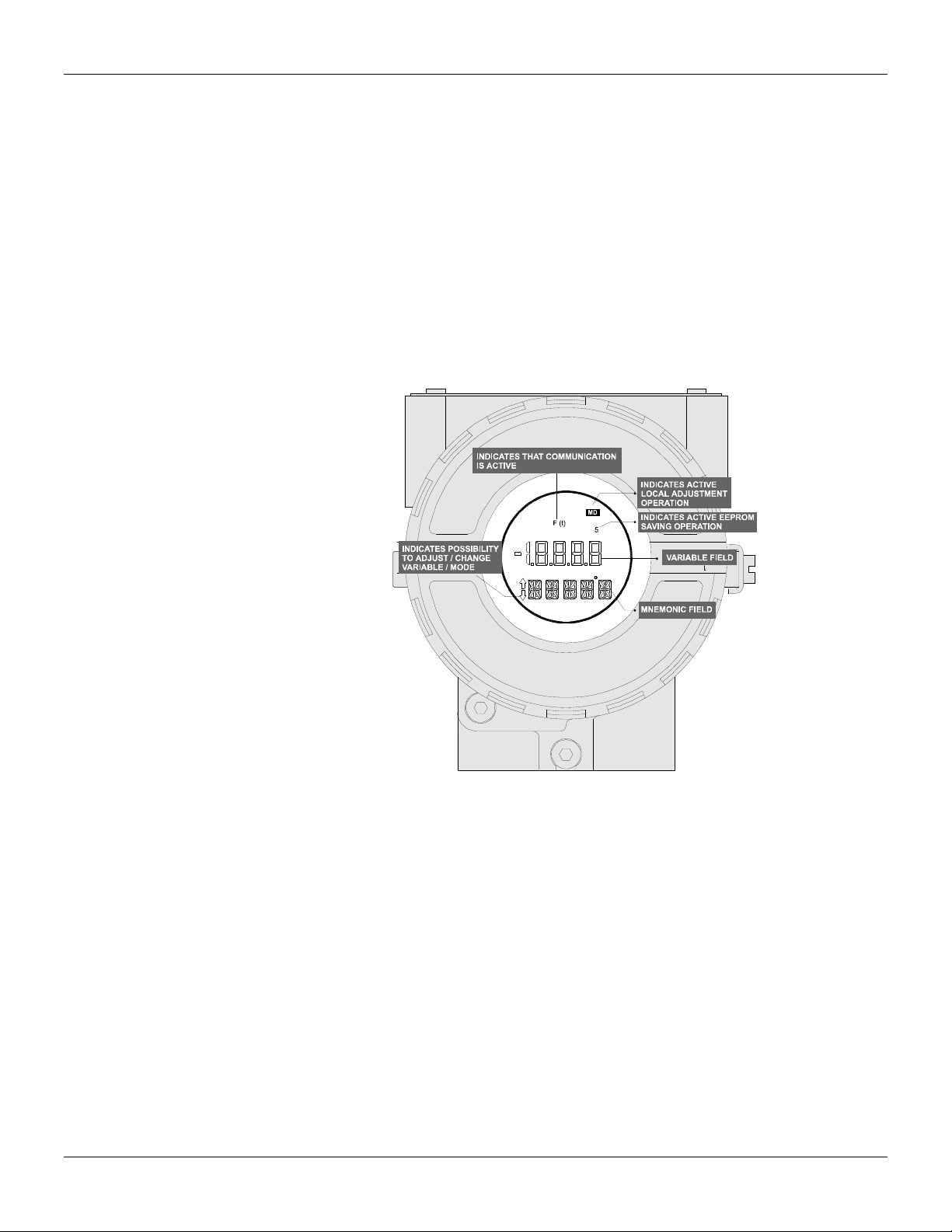

Display Controller

Receives data from the CPU identifying which segments on the liquid crystal display use to turn on.

The controller drives the backplane and the segment control signals.

Local Adjustment

There are two switches that are magnetically activated. The magnetic tool without mechanical or

electrical contact can activate them.

Figure 2.2 - LCD Indicator

Table of contents

Other SMAR Transmitter manuals

Popular Transmitter manuals by other brands

Intercoax

Intercoax Ipify ECP-2704R-4T-PKG Quick install guide

Velleman

Velleman VM121 manual

Air Monitor

Air Monitor ELECTRA-flo G5 Installation and operation manual

RF Central

RF Central RFX-NLL Operator's manual

AMG

AMG AMG4783E-DR-SF instruction manual

Broadcast Warehouse

Broadcast Warehouse TX 25/50 Technical manual