8

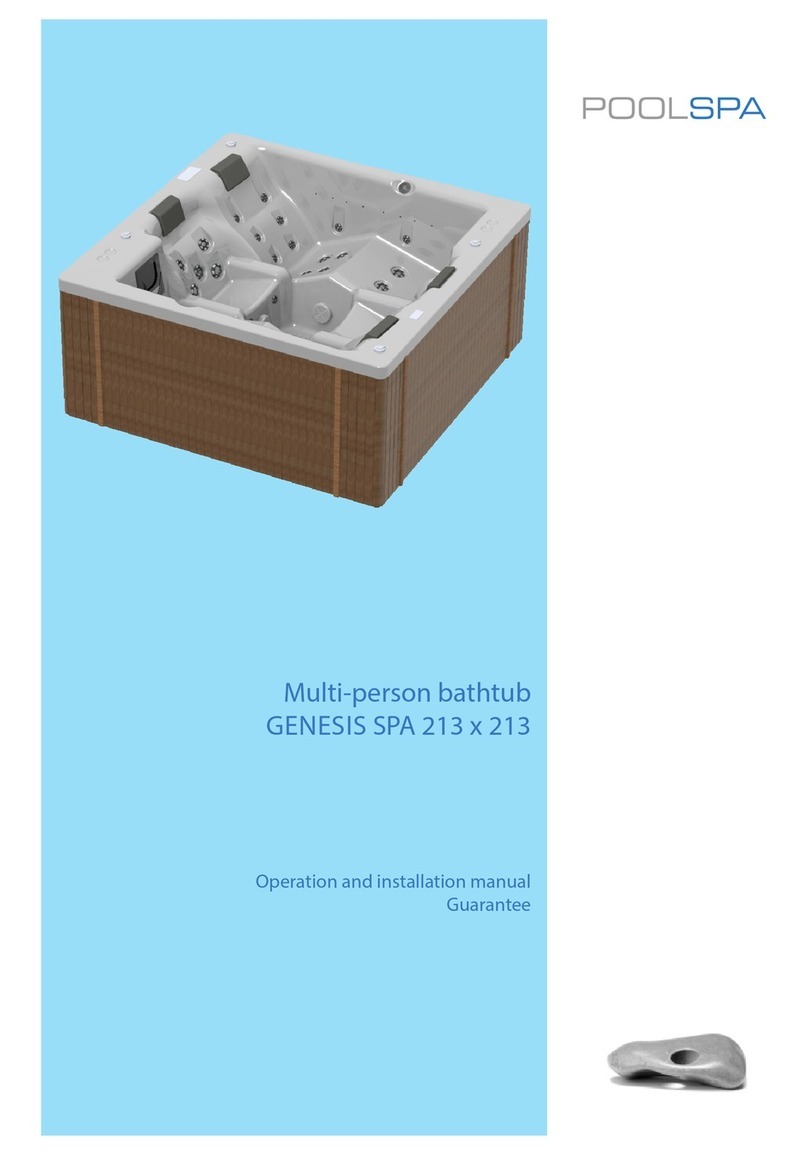

2. INSTALLATION PLACE PREPARATION

- The SPA bath can operate in both closed and open spaces.

- The SPA bath should be installed on a hard substrate to avoid equipment settlement.

- When the SPA bath is located in a closed space, enough space should be provided to carry the equipment in.

- Dimensions of a foundation plate on which the SPA bath is to be installed should be large enough to enable proper

arrangement of legs, conduits and cables.

- A method of the SPA bath emptying should be kept in mind. The substrate must be leveled.

- Note also walls and ceiling material. They should be resistant against water vapour volatizing during the SPA bath operation.

- Because of water splashing during SPA bath use, its substrate must be made of highly water-resistant material, such

as glace or plastic coatings. Floor finish must be appropriately protected against bacteria breeding in a wet environment.

Special rugs or floor finishes applied in sailing should be used. Parquet or other wooden floor are not recommended,

unless they were subjected to an appropriate processing like wood used for gardening or outdoor constructions. Ensure

that the floor hydraulic gradient towards the local floor sewer inlet is 2%.

3. INSTALLATION OF SPA BATH AND ACCESSORIES

- Proper SPA bath operation requires its installation on a durable and carefully leveled substrate, e.g. on 10 cm thick

concrete plate, to avoid equipment settlement.

- Weight of the fully water-filled SPA bath with 3 bathing persons amounts to about 1200 kg. The pressure exerted on

the substrate amounts to 360 kg/m2.

- After the bath installation height is set, a concrete block on which both stationary and telescopic legs will lean should

be prepared.

- Pit and concrete block dimensions should be large enough for proper placement of legs, piping and cables.

- After telescopic legs are installed, bath crown should be leveled.

- Fasten legs to the concrete block in such a way they are not able to move accidentally.

- All connections of accessories to the bath should be made of glue-joined pipes and fittings. Do not use metal pipes

and components.

- After the bath is filled with water check joints and connections for their leakproofness.

- Do not fill the space around the bath with any material. Access to all pipes and connections should be ensured.

- Accessories should be installed very carefully. It is the best to install them in an air-conditioned space and in a distance

to the bath not exceeding 10 m horizontally. Height of foundation plate on which accessories are installed should not be

bigger than that of the bath foundation plate. Also, accessories should not be installed more than 2,5 m below the bath

level. When distances are larger consult manufacturer service.

- It is advisable to locate a floor sewer inlet within the bath installation area and below its level.

4. ELECTRICAL CONNECTION

Electrical system connection to the power network should be performed by an authorized electrician.

Internal connections of accessories are factory-made.

The SPA bath electrical system should be protected with balanced-current circuit breaker with 30 mA rated

switch-off value, as well as with 40 A magnetic - thermal circuit breaker equipped with all poles disconnection

mechanism and at least 3 mm opening distance. Both circuit breakers should be located outside safety

zones marked on Figure 1.

4.1. Grounding

Proper operation of balanced-current circuit breaker requires a grounded system according to provisions in force, as

well as equalizer connections installed in the apartment.

4.2. Feeder cable location

The SPA bath feeder cable should be permanently connected to the electrical network, in no case through a wall socket.

Electrical system should be made according to the requirements for low voltage systems in force. Therefore it is impor-

tant to have in mind that the SPA bath installation creates 4 safety zones as shown in Figure 1. So, the feeder cable

should be located in zone 3 or on an suspended ceiling more than 2.25 m overhead.

4.3. Power supply connection

When connecting the power supply, note that:

- The SPA bath electrical power supply should be permanently connected to the power network.

-Cable used should fulfill appropriate low voltage system requirements. It should be remembered that yellow-green

grounding wire should be at least 40 mm longer than phase and neutral wires so as to be disconnected as the last one

in case of violent pulling.

- Power supply connection under the SPA bath can be made only when at least IPX5 protection level is ensured and the

connection is at least 20 cm above the floor.