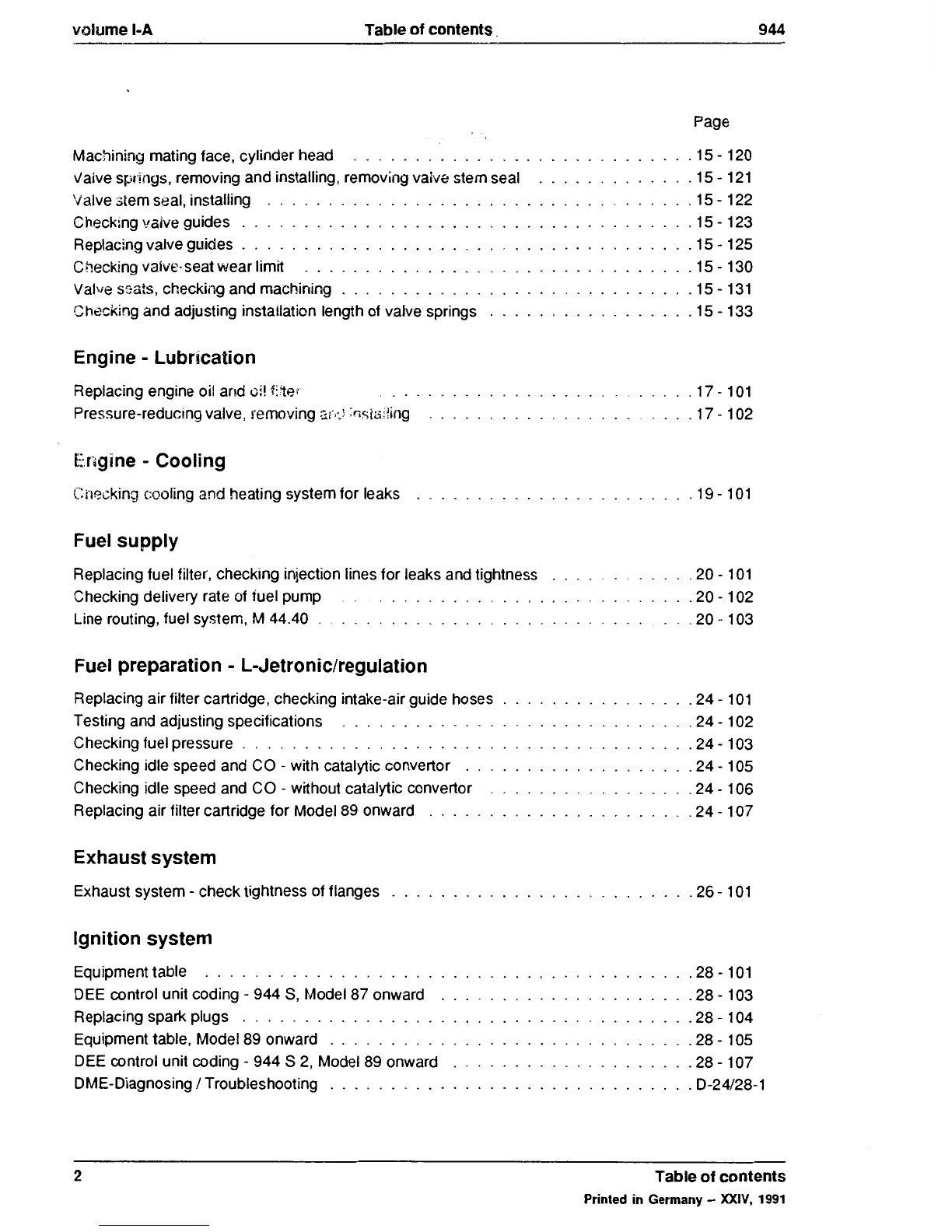

944 Table

of

contents volume

1-A

Page

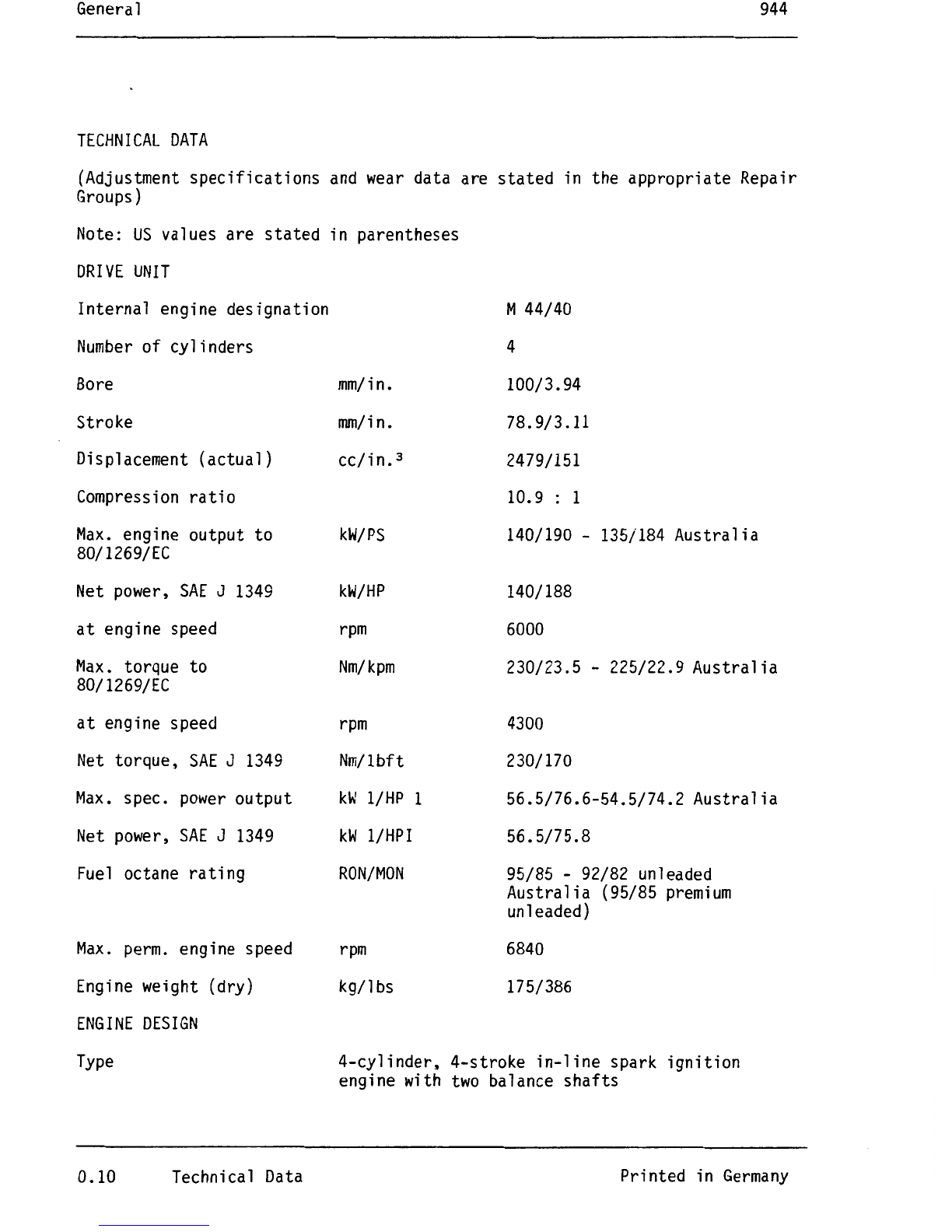

General

Technicaldata

...........................

0.9

Maintenance, Self-diagnosis

Fault diagnosis, DEE control unit

Connecting into the vehicle -944 S .

Starting fault diagnosis . . . . . . . .

Functional test -actuator and input signal .

List of test codes . . . . . . . . .

System adaptation

Knock detection .

Troubleshooting . .

List of fault codes .

Clearing fault memory

Operating conditions for start of diagnosis

Operating instructions for System Tester 9288

Engine, Crankcase

Tightening torques for engine (16-valve)

Tolerances and wear limits

...

Engine, removing and installing

....

Engine, Crankshaft drive, Pistons

Notes on assembly for pistons, from Model 87 onward

Checking pistons and cylinder bore . . .

Pistons from Model

89

onward . . . . . .

Installing cover for oil-centrifuge partition

Engine, Cylinder head, Valve drive

Camshaft setting, checking and adjusting . . . . . . . . . . . .

Camshaft setting, checking and adjusting for Model 89 onward

Applying the TDC mark on the camshaft sprocket . . .

Camshafts and cylinder head, removing and installing .

Cylinder head, installing and tightening

Camshafts,installing

Camshaftseal, installing . . . . . . . .

Camshaftspecifications . . . . . . . . .

Chain tensioner, removing and installing

Cylinder head, disassembling and assembling

Valve springs, removing and installing with Sauertool

Table

of

contents

Printed

in

Germany-

XXIV,

1991

03-

03-

3

03-

5

03-

7

03-

13

03-

15

03-

17

0:1

-19

03-29

03-31

03-32

03-33

10-0101

10-0102

10-

101

13-101

13-

102

13-

103

13-

105

15-

101

15-

104 a

15-

104 b

15-

105

15-110

15-111

15-112a

15-112b

15-113

15-115

15-118

1