3

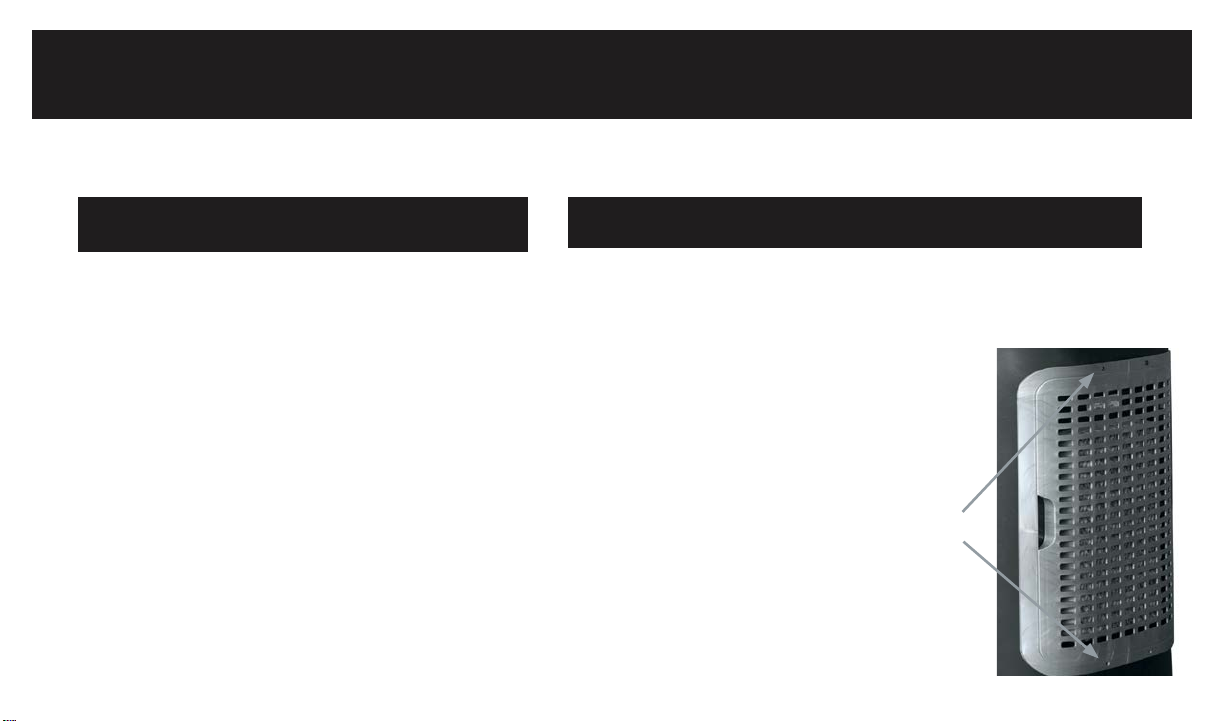

DIGITAL CONTROL PANEL

The user interface includes touch sensitive buttons for operation of the Portacool Islander. The user interface also includes status indicator

LEDs and a 7-segment display to show the cooling unit’s status.

Power

The green Power LED is illuminated when the unit is plugged in.

Water level

The red water level LED is illuminated when the oat switch detects a low water level and the pump is not turning on. This LED

ashes if the pump is running during a low water occurrence to indicate that more water needs to be added in order to continue

running the pump.

Timer

The controller features ve pre-programmed modes which control the fan / pump sequence for a pre-dened period. The LED

ashes slowly if continuously held and ashes quickly if the timer is enabled and then the Pump or Fan buttons are continuously

held, prompting the user to turn o the timer in order to exit fan and pump operation. The green Timer LED is illuminated when the Timer

button is activated. Each touch of the program button cycles through the ve modes: 1HR, 2HR, 4HR, 8HR, and TIMER OFF. During the

program run, the user can adjust the maximum fan speed with the up/down buttons. When the program is active, the Timer LED will be on

and, for ve seconds, the user will be shown which program (1H, 2H, 4H, or 8H) is active.

Pump

Press the pump button once to power on and again to power o. The green Pump LED is illuminated when the pump is enabled.

The LED ashes slowly if continuously held and the timer is disabled.

Fan

When the fan is o, touch the fan button once to turn the fan on in full speed. When the fan is on, touch of the Fan button again

to turn the fan o. The green Fan LED is illuminated when the fan is active. The LED ashes slowly if continuously held and the

timer is disabled.

Speeds

The buttons control the air velocity of the unit. Beginning with “Lo”, or 50% air ow, up to “Hi” or 100% airow and increasing

in ve percent increments.

7-Segment LED Display

LEDs are used to display the status of the cooling unit. The LED ashes slowly if continuously held and ashes quickly if the

timer is enabled and then the Pump or Fan buttons are continuously held, prompting the user to turn o the timer in order to exit

fan and pump operation.

Two digits display the unit’s tempera-

ture, fan speed, and timer program. If

the unit does not have a temperature

sensor connected, the display will

constantly show fan speed. If the unit

does feature a temperature sensor,

then the temperature is displayed

unless: a fan speed change is being

called upon either by means of the

up/down button or by the timer’s

program. When a fan speed change

is requested, the fan speed will be

displayed for ve seconds before

returning to the unit temperature.

LOCK OUT FEATURE

If the operator would like to lock

settings so that they can’t be adjusted, simply press the “up” arrow and the fan button simultaneously to lock the controls. To unlock, press the

“down” button and the fan icon. When enabled, “L-E”, or “Lock Enabled”, will be displayed in the LED.

PRE-PROGRAMMED TIMER FUNCTION

1) PUMP STARTS (INCLUDES FIVE SECOND DELAY TO ALLOW WATER TO START REACHING THE PADS)

2) FAN STARTS AT 100% (HI) SPEED (A “KICK START” FOR BEST VARIABLE SPEED MOTOR OPERATION)

3) FAN RAMPS DOWN TO 50% SPEED

4) FAN RAMPS UP TO FULL SPEED IN 10% STEPS AT ONE MINUTE INTERVALS (BEGIN INCREASING AIRFLOW AS THE PADS WET

OUT FOR BEST EFFICENCY)

5) FAN RUNS AT MAXIMUM SPEED FOR THE DURATION OF THE TIMER SETTING (100% SPEED IS DEFAULT, OR IT CAN BE WHATEVER

THE USER SELECTS)

6) PUMP SHUTS OFF WHEN TIMER SETTING EXPIRES

7) FAN RAMPS DOWN TO 50% SPEED

8) FAN RUNS 30 MINUTES (PAD DRYING PERIOD)

9) FAN SHUTS OFF

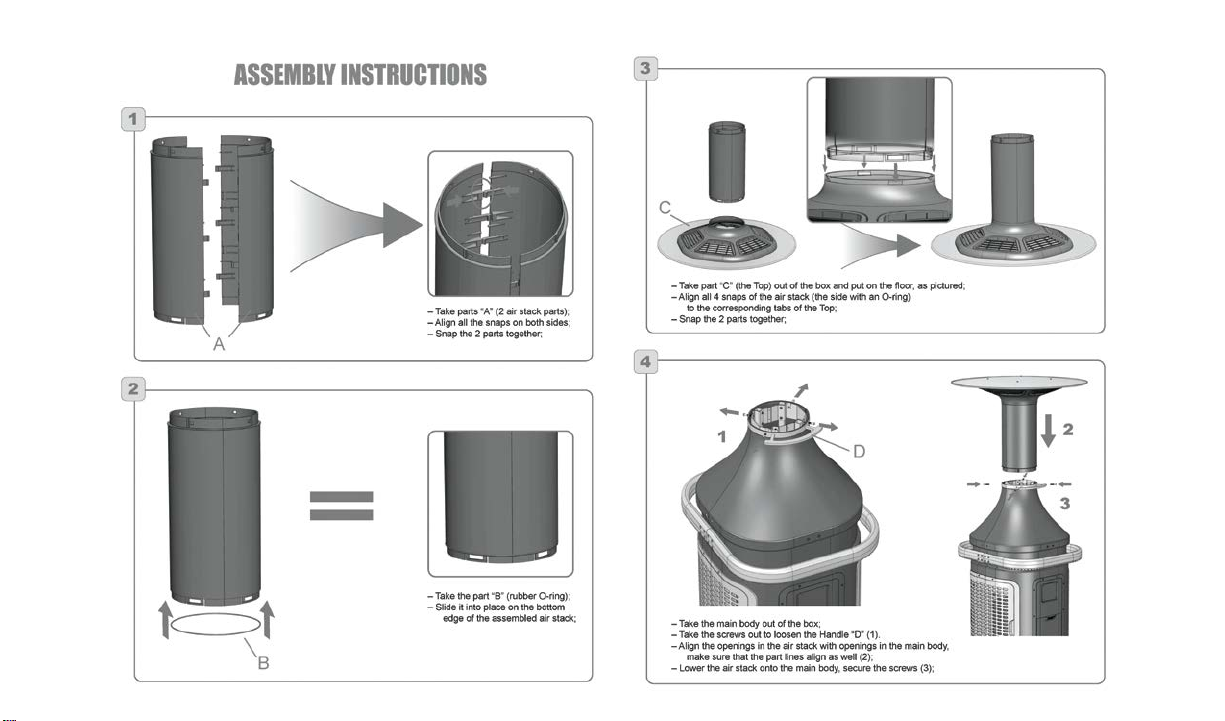

1

2

3

4

5

6

7

2

1

3

4

5

6

7