Les risques suivants peuvent survenir durant l’emploi normal de ce produit:

Les solvants 1,1,1 - trichloroéthane et

dichlorométhane peuvent avoir une réaction

chimique au contact de l’aluminium utilisé dans la

majorité des équipements de pulvérisation—et ce

pistolet et godet—peuvent provoquer un risque

d’explosion et entraîner des blessures graves ou

la mort.

Lire l’étiquette ou la fiche signalétique sur le matériau

utilisé pour la pulvérisation.

1. Ne jamais utiliser de matériau de revêtement qui

contient des solvants.

2. Ne jamais utiliser ces solvants pour nettoyer ou

purger l’équipement.

3. En cas de doute sur la compatibilité du matériau,

communiquer avec le fournisseur du matériau.

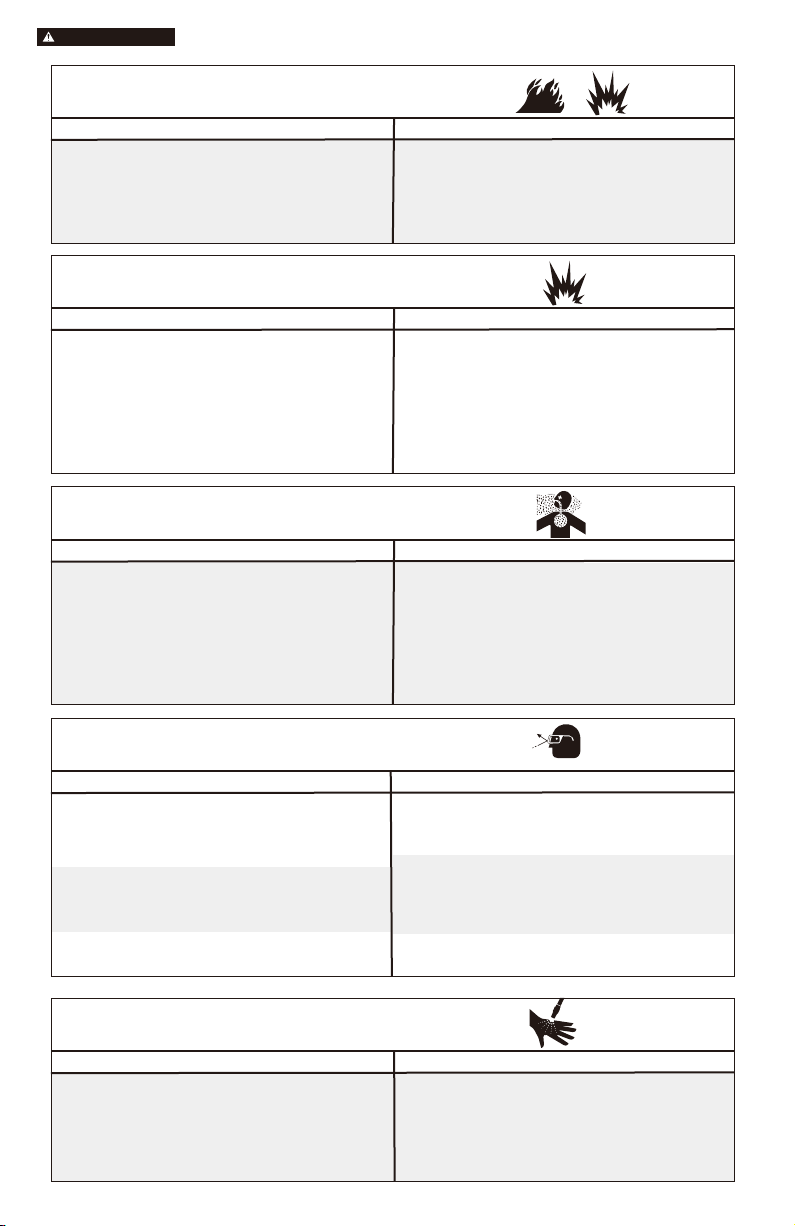

RISQUE

COMMENT PRÉVENIR

CE QUI POURRAIT ARRIVER

Risque d’explosion ou de feu – matériaux inflammables

En pulvérisant les peintures ou matériaux, ils

peuvent se briser en très petites particules et se

mélanger à l’air. Certaines peintures et matériaux

deviendront alors extrêmement inflammables et

cela pourrait entraîner des blessures graves ou la

mort.

Ne jamais vaporiser près des flammes nues ou des

flammes pilotes des cuisinières ou appareils de

chauffage.

Ne jamais fumer pendant les travaux de pulvérisation.

Prévoir une ventilation suffisante pour les travaux à

l’intérieur.

RISQUE

COMMENT PRÉVENIRCE QUI POURRAIT ARRIVER

Risque d’explosion – matériaux incompatibles

RISQUE

CE QUI POURRAIT ARRIVER

Risque d’inhalation

Quelques peintures, revêtements et solvants

peuvent endommager les poumons, et causer

des brûlures s’ils sont aspirés ou entrent en contact

avec la peau ou les yeux.

Porter le masque ou respirateur NIOSH approuvés

et les vêtements de protection conçus pour être

portés pour votre travail spécifique et les matériaux

de pulvérisation. Quelques masques offrent

seulement une protection limitée contre les toxiques

et les solvants nocifs. Consultez un expert en

sécurité ou un hygiéniste industriel si vous avez des

doutes au sujet de votre équipement ou les matériaux

L’exposition prolongée à la pulvérisation peut

causer des dommages auditifs permanents.

Les pistolets de pulvérisation fonctionnent à des

pressions et vélocités suffisamment élevées pour

pénétrer le corps humain et la chair des animaux,

et pourraient entraîner une amputation ou une

blessure grave.

1. Consulter un médecin immédiatement!

Ne jamais placer la main devant la buse.

Ne pas diriger la pulvérisation vers soi et autrui.

RISQUE

COMMENT PRÉVENIRCE QUI POURRAIT ARRIVER

Risque d’objets volants

Risque de pénétration

Certaines pièces sont sous pression lorsque le

pistolet est branché sur les conduites d’air sous

pression. Ces pièces peuvent être projetées si le

pistolet est démonté.

Débrancher le pistolet de la conduite d’air, ou

dépressuriser complèment la conduite d’air lorsque

le pistolet doit être démonté.

Ne jamais pointer la buse ou le pulvérisateur en

direction d’une personne ou d’une partie du corps.

Toujours porter de lunettes de protection ANSI 278.1

approuvées ou des lunettes pendant la pulvérisation.

Toujours porter une protection auditive pour utiliser

le pistolet.

L’air comprimé peut propulser la saleté, les copeaux

de métal, etc., et pourra entraîner des blessures

AVERTISSEMENT

COMMENT PRÉVENIR

RISQUE

COMMENT PRÉVENIRCE QUI POURRAIT ARRIVER