ACS CANopen Manual Version 20110928

2 of 44

AC CEL ENS ( AC S) CANo pen

TABLE OF CONTENTS

General Security Advise ............................. 3

About T is Manual ...................................... 3

1. Introduction.............................................. 4

1.1 ACCELENS (ACS) .......................................... 4

1.2 CANopen Interface ......................................... 4

1.3 ACS CANopen ................................................ 5

1.4 Typical Applications of ACS ............................

2. ACS – Modes And Parameters ............... 6

2.1 Operating Modes ............................................ 7

2.2 Transmission Modes ....................................... 8

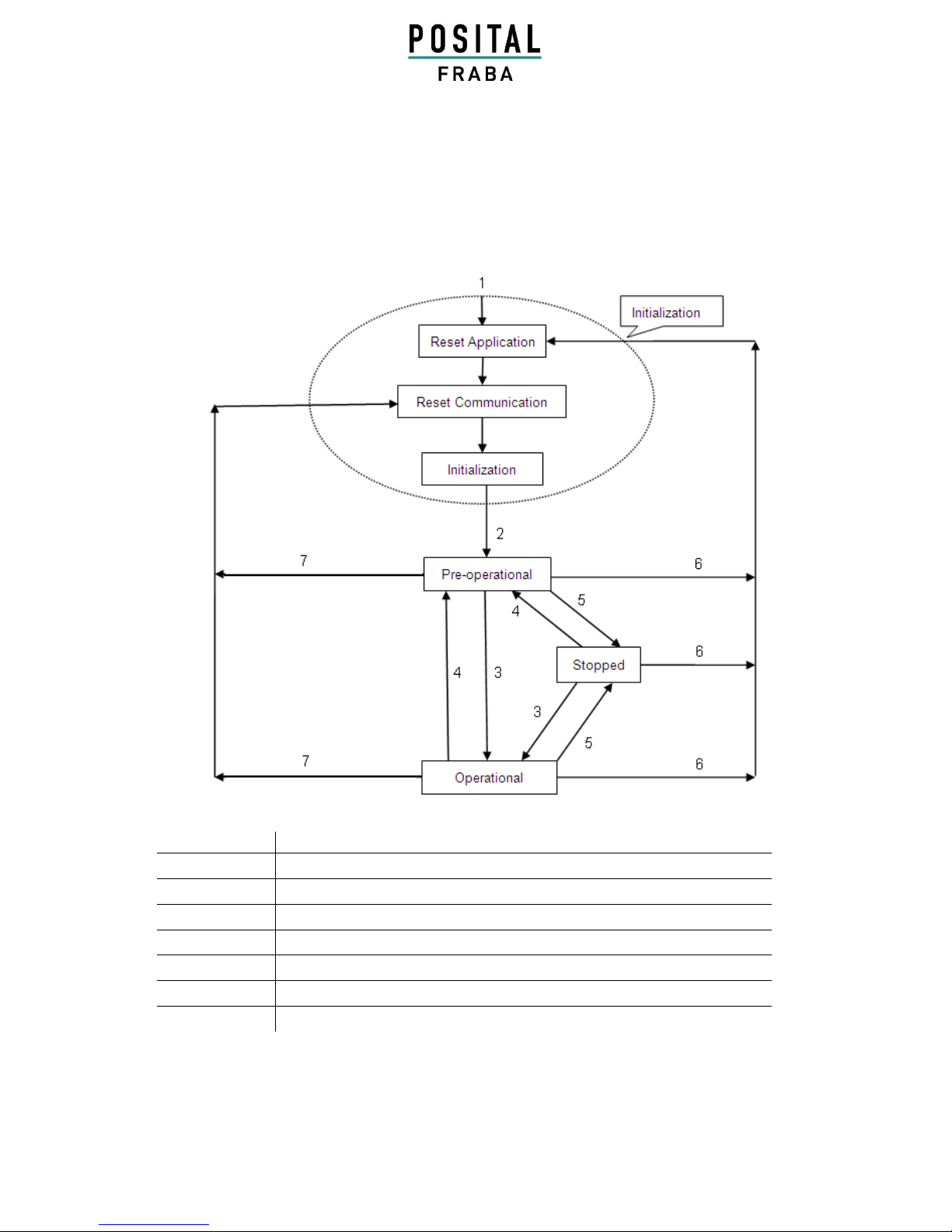

2.3 Boot-Up Procedure ......................................... 9

3. Installation.............................................. 10

3.1 Accessories ................................................... 10

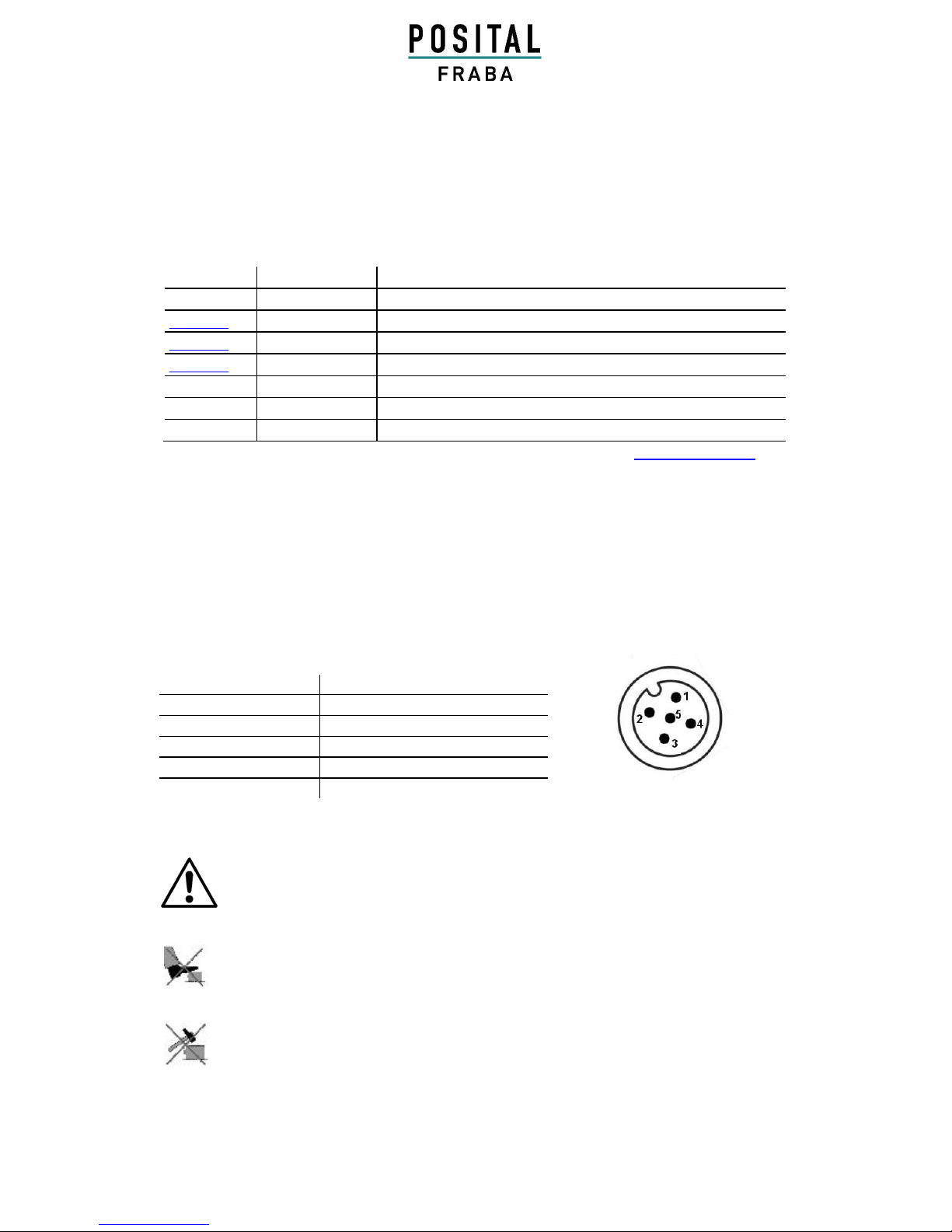

3.2 Pin Assignement ........................................... 10

3.3 Installation Precautions ................................. 10

3.4 Mounting Instructions .................................... 11

3. Measurement Axes ....................................... 12

4.ACS Software Configuration ................. 14

4.1 Important Factory Settings ............................ 14

4.2 Active Programming Objects ......................... 14

4.3 Programmable Parameters ........................... 15

4.4 PDO Transmission ........................................ 17

4.5 Explicit Exchanges (SDO) ............................. 19

5. Working Wit Sc neider PLC ............... 21

5.1 Introduction ................................................... 21

5.2 Network Initialization ..................................... 21

5.2.1 Hardware ................................................... 21

5.2.2 Software Project Information ...................... 22

5.3 Configuration ................................................. 25

5.4 Debugging ..................................................... 27

5.4 Run................................................................ 29

6. Troubles ooting ................................... 32

Appendix A: ACS CANopen Objects ....... 33

Object 1000h: Device Type ................................. 33

Object 1001h: Error Register ............................... 33

Object 1003h: Pre-Defined Error Field ................ 34

Object 1005h: Cob-Id Sync ................................. 34

Object 1008h: Mfr Device Name ......................... 34

Object 1009h: Mfr Hardware Version .................. 34

Object 100ah: Mfr Software Version ................... 34

Object 100ch: Guard Time .................................. 35

Object 100dh: Life Time Factor ........................... 35

Object 1010h: Store Parameters ......................... 35

Object 1011h: Restore Parameters ..................... 35

Object 101 h: Consumer Heartbeat Time ........... 3

Object 1017h: Producer Heartbeat Time ............. 3

Object 2200h: Cyclic Timer ................................. 3

Object 2300h: Save Parameter With Reset......... 3

Object 2 00h: Preset X/Z-Axis ........................... 37

Object 3000h: Node Number ............................... 37

Object 3001h: Baudrate ...................................... 37

Object 3100h: Moving Average Filter .................. 38

Object 000h: Resolution* ................................... 38

Object 010h: Position Value X/Z-Axis................ 38

Object 012h: Preset X/Z-Axis ............................ 38

Object 020h: Position Value Y-Axis ................... 39

Appendix B: Ordering Code ..................... 39

Appendix C: Output Grap s ...…………...40

Glossary ..................................................... 40