Version 02/09 UME-MCD-CA 2

ABSOLUTE ROTARY ENCODER

CANOPEN

Table of Contents

Main Features........................................................1

Mechanical Structure.............................................1

Programmable Parameters....................................1

Electrical Features.................................................1

Table of Contents.................................................2

General Security Advise......................................4

About this Manual................................................4

1. Introduction......................................................5

1.1 General CANopen Information.........................5

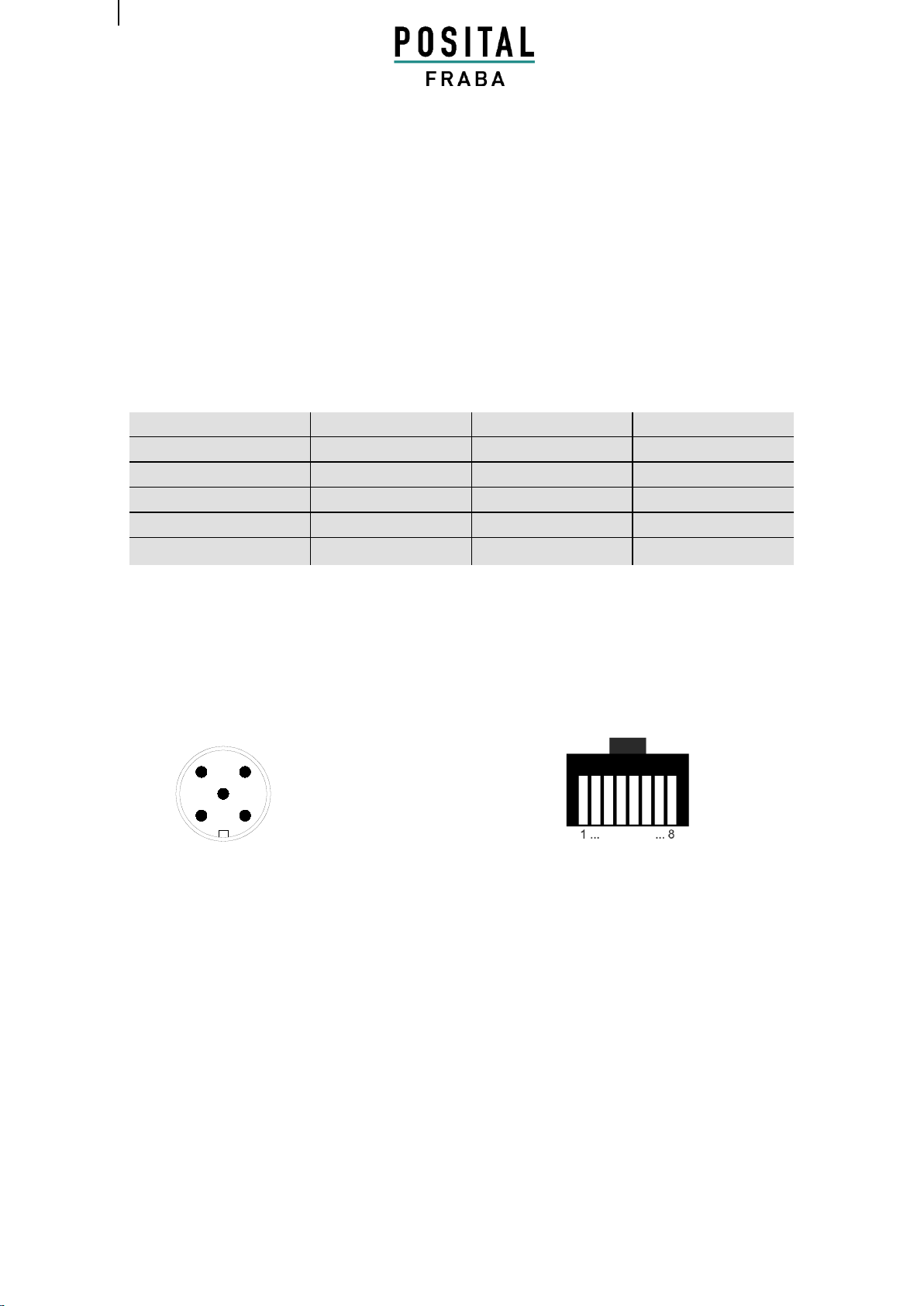

2. Installation........................................................7

2.1 Electrical Connection.......................................7

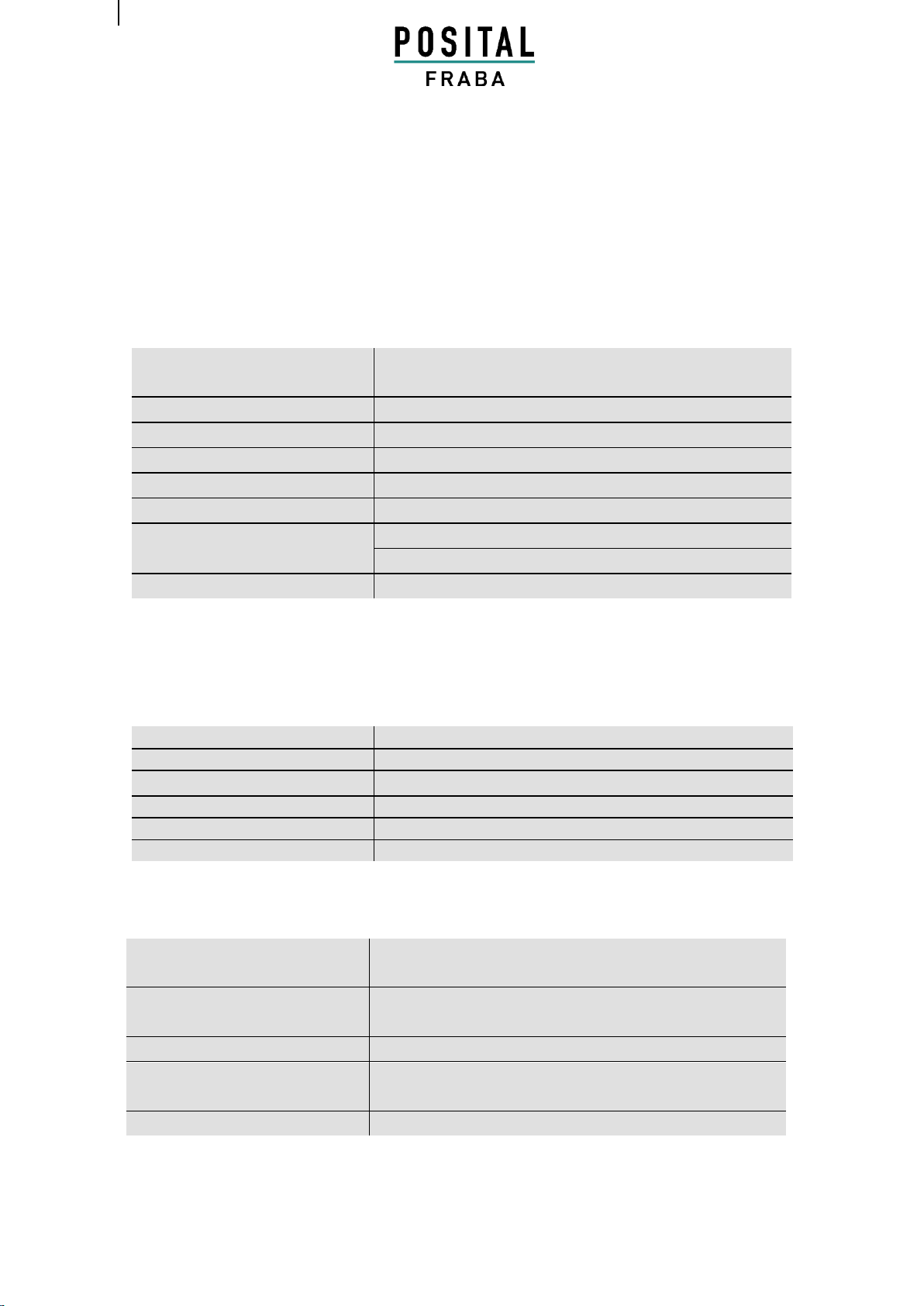

3. Technical Data..................................................9

Electrical Data........................................................9

Sensor data............................................................9

Tab. 3 Sensor data....................................................9

Flange..................................................................10

Synchro (S)..........................................................10

Blind hollow shaft (B)...........................................10

Clamp (C) ............................................................10

Minimum Mechanical Lifetime..............................10

Cable ...................................................................10

4. Configuration .................................................11

4.1 Operating Modes ...........................................11

4.1.1 General.......................................................11

4.1.2 Mode: Preoperational..................................11

4.1.3 Mode: Start - Operational............................11

4.1.4 Mode: Stopped............................................11

4.1.2 Reinitialization of the Encoder.....................12

4.2 Normal Operating...........................................12

4.3 Storing Parameter..........................................13

4.3.1 List of storable Parameter...........................13

4.3.1 Storing Procedure.......................................13

4.4 Restoring Parameters....................................14

4.5 Usage of Layer Setting Services (LSS)..........14

5. Programmable Parameters ...........................16

5.1 Programming example: Preset Value ............17

5.1.1 Set Encoder Preset Value...........................17

5.2 Communication Profile DS301 specific

objects from 1000h - 1FFFh.................................18

5.3 Manufacturer specific objects 2000h –

5FFFh..................................................................19

5.4 Application specific objects 6000h –67FEh .. 19

5.5 Object Descriptions ....................................... 20

Object 1000h: Device Type ................................. 20

Object 1001h: Error Register............................... 21

Object 1003h: Pre-Defined Error Field ................ 21

Object 1005h: COB-ID Sync................................ 22

Object 1008h: Manufacturer Device Name.......... 22

Object 1009h: Manufacturer Hardware Version... 22

Object 100Ah: Manufacturer Software Version.... 22

Object 100Ch: Guard Time.................................. 23

Object 100Dh: Life Time Factor........................... 23

Object 1010h: Store Parameters......................... 23

Object 1011h: Restore Parameters..................... 24

Object 1012h: COB-ID Time Stamp Object......... 24

Object 1013h: High Resolution Time Stamp........ 24

Object 1014h: COB-ID Emergency Object .......... 25

Object 1016h: Consumer Heartbeat Time........... 25

Object 1017h: Producer Heartbeat Time............. 25

Object 1018h: Identity Object .............................. 26

Object 1020h: Verify configuration....................... 26

Object 1029h: Error behaviour............................. 26

Object 1800h: 1st Transmit PDO Communication

Parameter............................................................ 27

Object 1801h: 2nd Transmit PDO Communication

Parameter............................................................ 27

Event Timer......................................................... 28

Object 1A00h: 1st Transmit PDO Mapping

Parameter............................................................ 28

Object 1A01h: 2nd Transmit PDO Mapping

Parameter............................................................ 29

Object 1F50h: Download Program Area.............. 29

Object 1F51h: Program Control........................... 29

Object 2000h: Position Value .............................. 30

Object 2100h: Operating Parameters.................. 30

Object 2101h: Resolution per Revolution ............ 31

Object 2102h: Total Resolution ........................... 31

Object 2103h: Preset Value................................. 32

Object 2104h: Limit Switch, min. ......................... 32

Object 2105h: Limit Switch, max. ........................ 33

Object 2160h: Customer storage......................... 33

Object 2200h: Cyclic Timer PDO......................... 34