LIMITED WARRANTY

Warranty Coverage - Flex Innovations, Inc. and its authorized resellers (“Flex”)

warrant to the original purchaser that the product purchased (the “Product”) it

will be free from defects in materials and workmanship at the date of purchase.

Outside of Coverage - This warranty is not transferable and does not cover: (i)

Products with more than 45 days after purchased date; (ii) Damage due to acts

of God, accident, misuse, abuse, negligence,commercial use, or due to

improper use, installation, operation or maintenance; (iii) Modication of or to

any part of the Product; (iv) Product not compliant with applicable technical

regulations; (v) Shipping damage; (vi) Cosmetic damage

OTHER THAN THE EXPRESS WARRANTY ABOVE, FLEX MAKES NO OTHER

WARRANTY OR REPRESENTATION, AND HEREBY DISCLAIMS ANY AND ALL

IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED

WARRANTIES OF NONINFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE

HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIRE-

MENTS OF THE PURCHASER’S INTENDED USE.

Purchaser’s Solution - Flex’s sole obligation and purchaser’s sole and

exclusive remedy shall be that Flex will, at its option, either (i) service, or (ii)

replace, any Product determined by Flex to be defective. Flex reserves the right

to inspect any and all Product(s) involved in a warranty claim. Service or

replacement decisions are at the sole discretion of Flex. Proof of purchase is

required for all warranty claims. SERVICE OR REPLACEMENT AS PROVIDED

UNDER THIS WARRANTY IS THE PURCHASER’S SOLE AND EXCLUSIVE

REMEDY.

Limitation of Liability - FLEX SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUC-

TION OR COMMERCIAL LOSS IN ANY WAY, REGARDLESS OF WHETHER SUCH

CLAIM IS BASED IN CONTRACT, WARRANTY, TORT, NEGLIGENCE, STRICT

LIABILITY OR ANY OTHER THEORY OF LIABILITY, EVEN IF FLEX HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Further, in no event shall the liability of Flex exceed the individual price of the

Product on which liability is asserted. As Flex has no control over use, setup,

assembly, modication or misuse, no liability shall be assumed nor accepted for

any resulting damage or injury. By the act of use, setup or assembly, the user

accepts all resulting liability. If you as the purchaser or user are not prepared to

accept the liability associated with the use of the Product, purchaser is advised

to return the Product immediately in new and unused condition to the place of

purchase.

Law - These terms are governed by Florida law (without regard to conict of

law principals). This warranty gives you specic legal rights, and you may also

have other rights which vary from state to state. FLEX RESERVES THE RIGHT

TO MODIFY THIS WARRANTY AT ANY TIME WITHOUT PRIOR NOTICE.

Questions & Assistance - For customer support in your region, visit:

http://www.exinnovations.com/index.php/reseller-sub

Inspection or Services - If this Product needs to be inspected or serviced and

is compliant in the region you live and use the Product in, please contact your

regional Flex authorized reseller. Pack the Product securely using a shipping

carton. Please note that original boxes needs to be included, but are not

designed to withstand the rigors of shipping without additional protection.

Ship via a carrier that provides tracking and insurance for lost or damaged

parcels, as Flex is not responsible for merchandise until it arrives and is

accepted at our facility.

Warranty Requirements - For Warranty consideration, you must include

your original sales receipt verifying the proof of purchase date. Provided

warranty conditions have been met, your Product will be replaced free of

charge. Shipping charges are as follow: to Flex by customer, Flex out it is by

Flex. Service or replacement decisions are at the sole discretion of Flex.

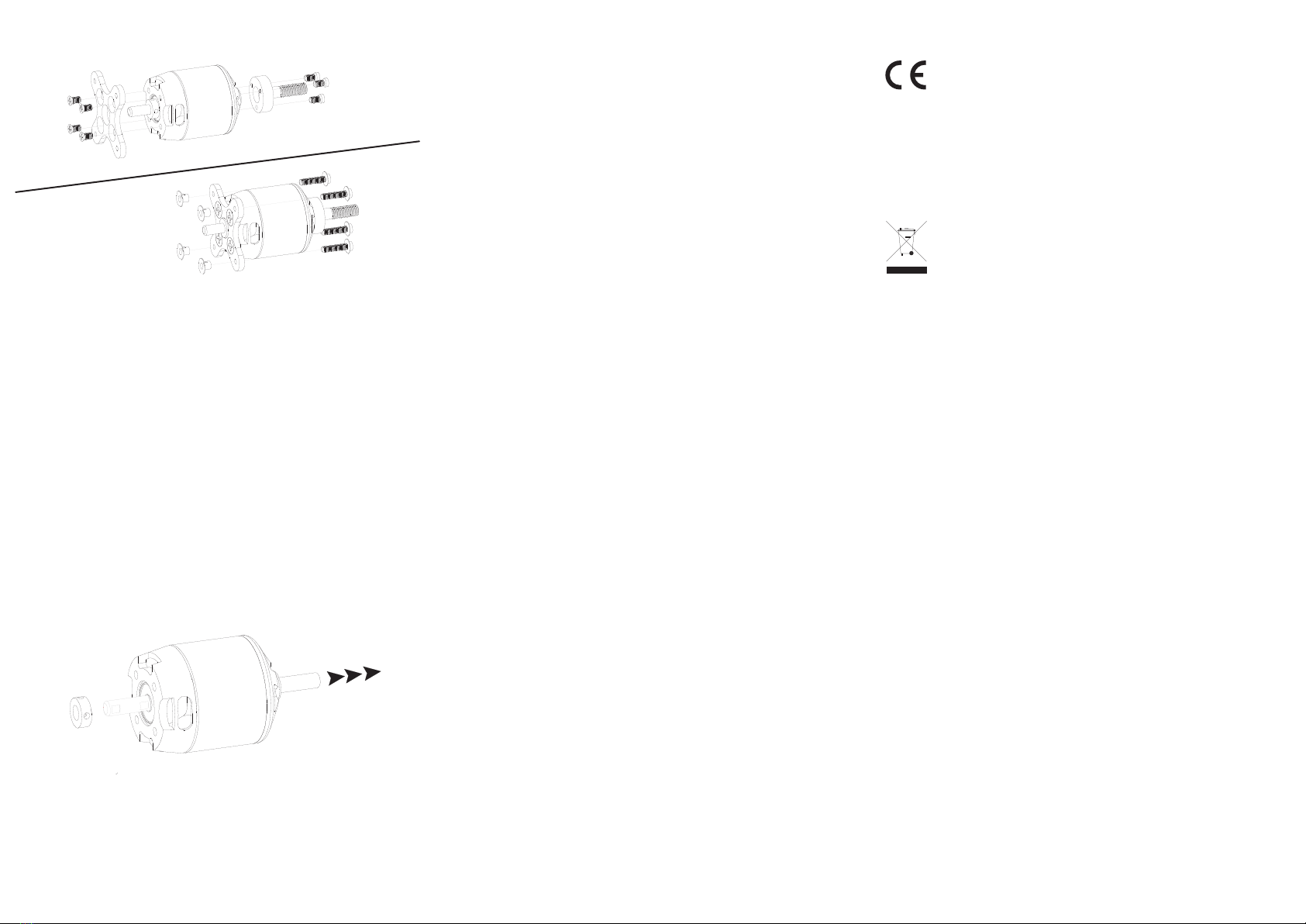

MOTOR MOUNTING USING X-MOUNT

The most common installation of brushless outrunner motors is to install the

X-mount on the rear of the motor and attach this mount to the rewall. Other

options exist for mounting motors including mounting in reverse directly to the

nose ring or using standos. Please consult the directions with your model to

ensure proper motor mounting and conguration. DO NOT install the X-mount

onto the motor until the rewall has been prepared for the motor mount.

1. Trial-t the aluminum X-mount on the model’s rewall and mark the

locations for the four screw holes and shaft (if applicable).

2. Using the appropriate size drill bit, drill out the four holes for the mounting

screws, and enlarge them properly for blind nut installation.

3. Install the (4) blind nuts on the rear side of the rewall. Run medium CA

around the perimeter of the blind nuts, but ensure that no adhesive enters

the threaded shank.

4. Attach the X-mount to the motor using (4) countersunk screws and a small

amount of blue threadlocker.

5. Attach the motor assembly to the rewall with the included socket head cap

screws and at washers.

6. Once satised with the nal assembly of the motor, apply blue threadlocker

to all mounting screws EXCEPT the prop nut.

CHANGING SHAFT POSITION

1. Loosen the set screws on the shaft collar and remove the collar from the shaft.

2. Loosen the set screw on the ange of the motor can (the rotating

portion of the motor)

3. Carefully push the shaft through the motor. A small hammer may be

required to lightly tap the shaft.

4. Reinstall the shaft collar against the main bearing, apply blue threadlocker to

the set screws and tighten them

5. Apply blue threadlocker and tighten the screw on the ange of the motor can.

COMPLIANCE INFORMATION FOR THE EUROPEAN UNION

Declaration of Conformity (In accordance with ISO/IEC 17050-1)

Product(s): Potenza 60 470Kv Motor

Item Number(s): FPZM1060A

The object of declaration described above is in conformity with the requirements of the

specications listed below, following the provisions of the EMC Directive 2004/108/EC.

EN55022:2010 + AC:2011

EN55024:2010

Instructions for disposal of WEEE by users in the European Union

This product must not be disposed of with other waste. Instead, it is the

user’s responsibility to dispose of their waste equipment by handing it over

to a designated collections point for the recycling of waste and electronic

equipment. The sepearate collection and recycling of your waste equipment

at the time of disposal will help to conserve natural resources and ensure

that it is recycled in a manner that protects human health and the

environment. For more information about where to drop o your waste

equipment for recycling, please contact your local city oce, your household

waste disposal service or where you purchased the product.